Telescopic bracket, steel box girder hoisting device and hoisting method

A telescopic bracket and steel box girder technology, applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve the problems of large investment, long construction period, time-consuming erection and disassembly, and achieve the effect of less consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Below, the present invention will be further described in conjunction with the accompanying drawings and specific implementation methods. It should be noted that, under the premise of not conflicting, the various embodiments described below or the technical features can be combined arbitrarily to form new embodiments. .

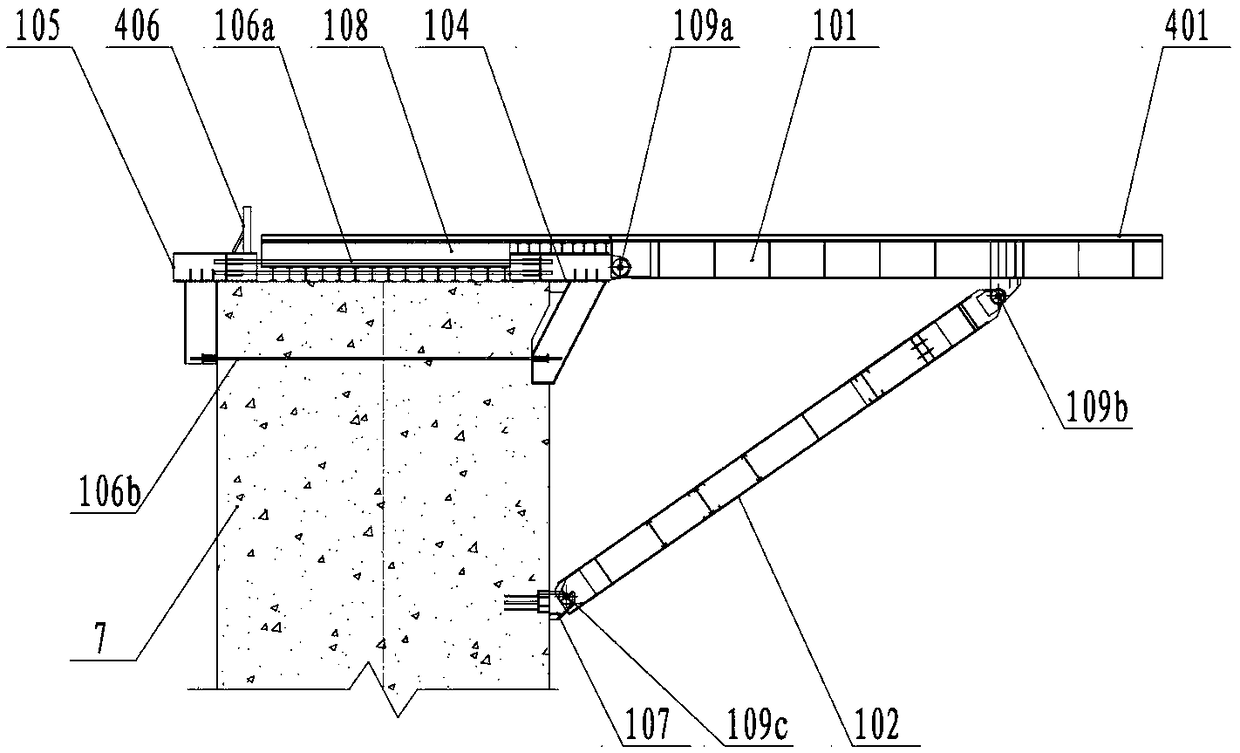

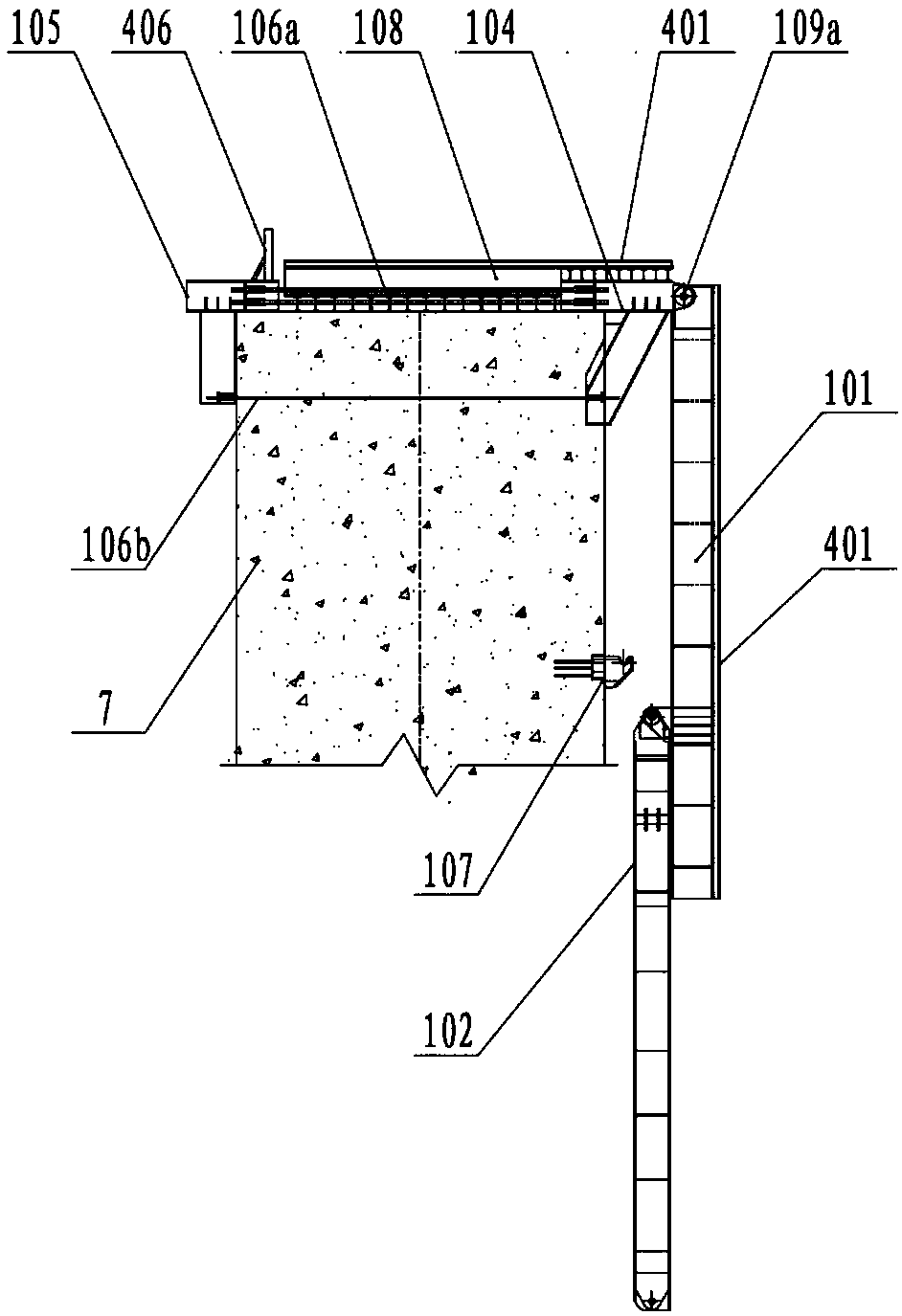

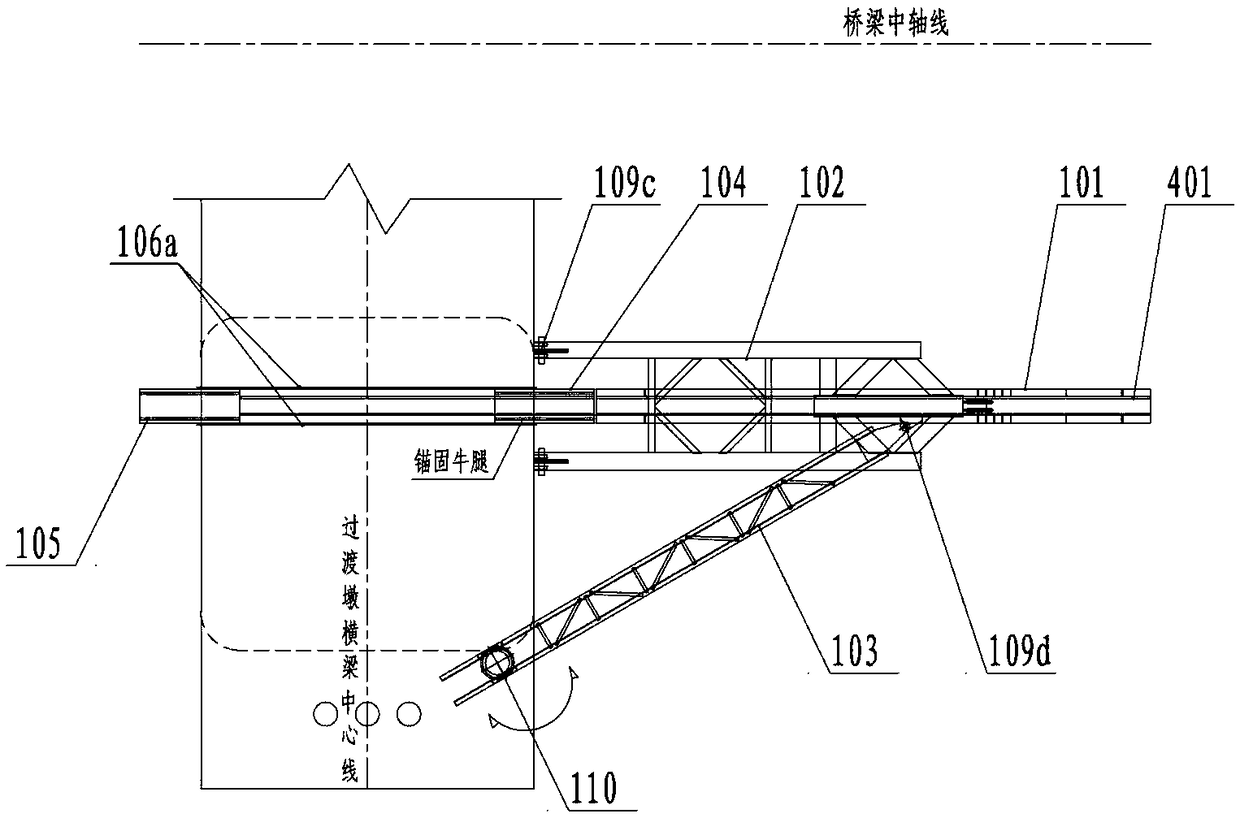

[0064] The telescopic bracket 1 of this technical solution is installed on the top of the transition pier 7 of the suspension bridge, and two are symmetrically installed and arranged according to the central axis of the bridge. After the telescopic bracket 1 is installed, it is divided into two states, namely the extended state and the retracted state. The structure of a single telescopic bracket 1 consists of a main beam 101, a vertical brace 102 for vertically supporting the main beam 101, a horizontal brace 103 for horizontally supporting the main beam 101, including an anchoring corbel 104 and a reverse pull corbel. 105 anchoring mechanism, anchori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com