The Construction Method of Removing Staged Wall and Temporary Support in Staged Construction of Deep Foundation Pit

A construction method and temporary support technology, applied in basic structure engineering, excavation, construction, etc., can solve problems such as secondary deformation of deep foundation pits, and achieve the effects of reducing environmental impact, improving construction efficiency, and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with accompanying drawing:

[0029] Please refer to Figure 1-5 , the present embodiment provides a method for constructing a basement structure in phases before and after a deep foundation pit, comprising the following steps:

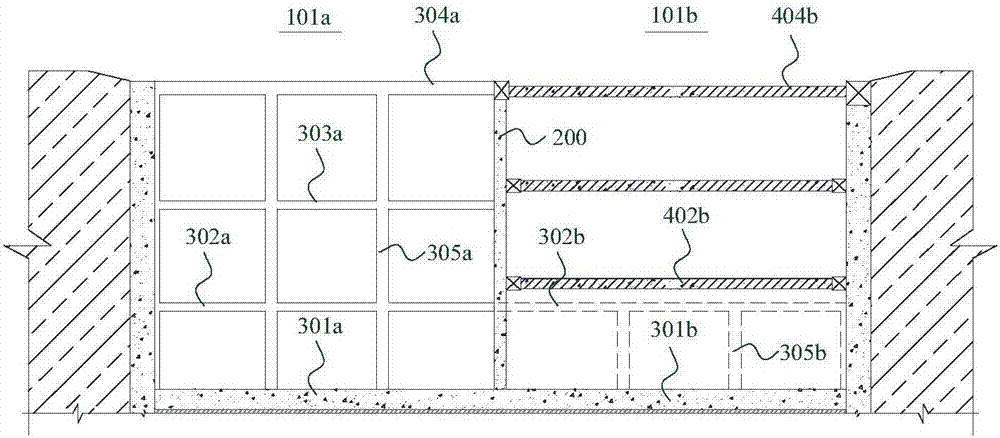

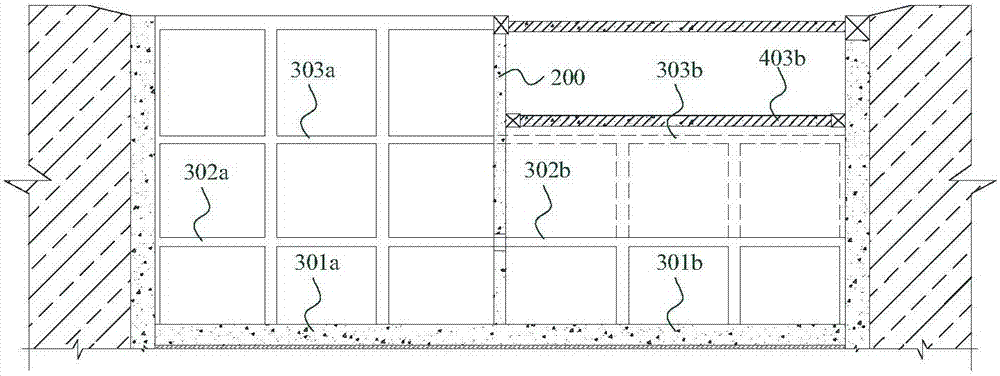

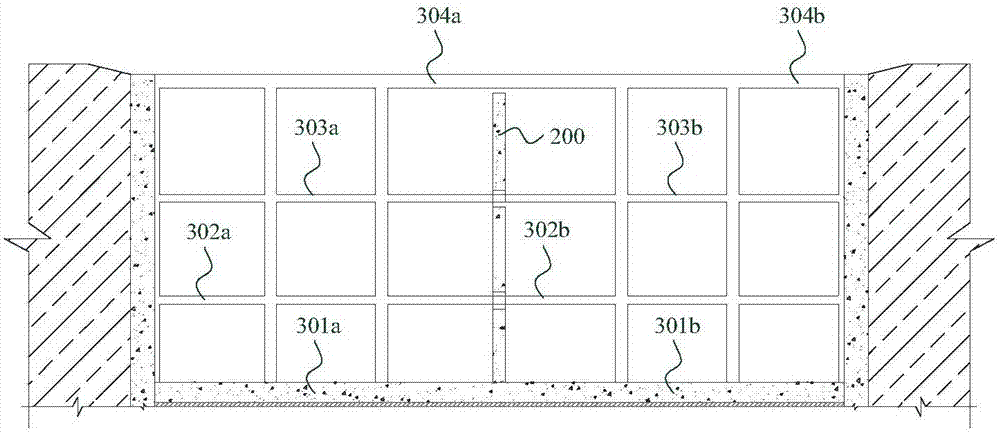

[0030] Step 1, construction staged wall 200, with the staged wall 200 as the boundary, carry out the construction of front pit 101a, form the basement structure of front pit 101a, wherein the basement structure includes at least one layer of structural beams and foundation floor 301a; Wherein the front pit 101a is Figure 1-3 The area on the left side of the middle stage wall 200, wherein the rear pit 101b is the area on the right side of the stage wall;

[0031] Step 2: Start the earthwork excavation of the rear pit 101b with the boundary of the stage wall 200, and carry out temporary support construction at the same time, and complete the foundation floor 301b of the rear pit 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com