Steel pipe straightening machining device and application method

A processing device and steel pipe technology, applied in the field of mechanical processing, can solve problems such as poor processing effect, achieve the effects of preventing offset, improving processing efficiency, and reducing steel pipe damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

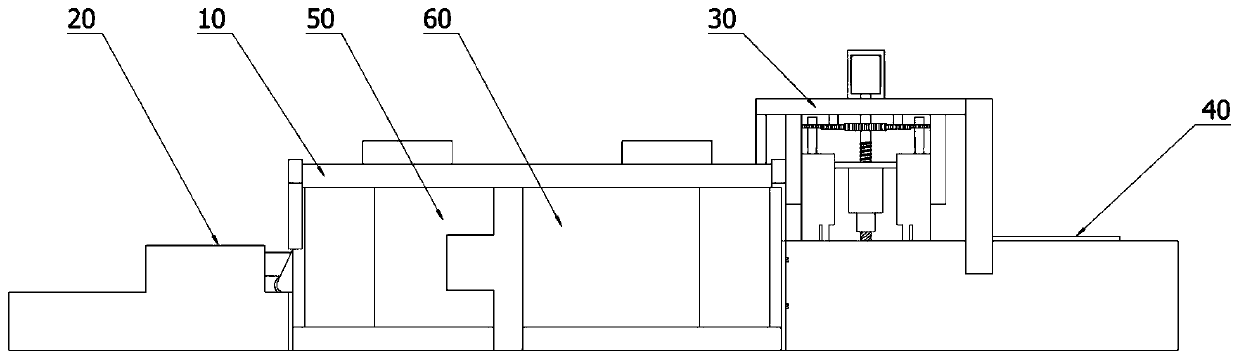

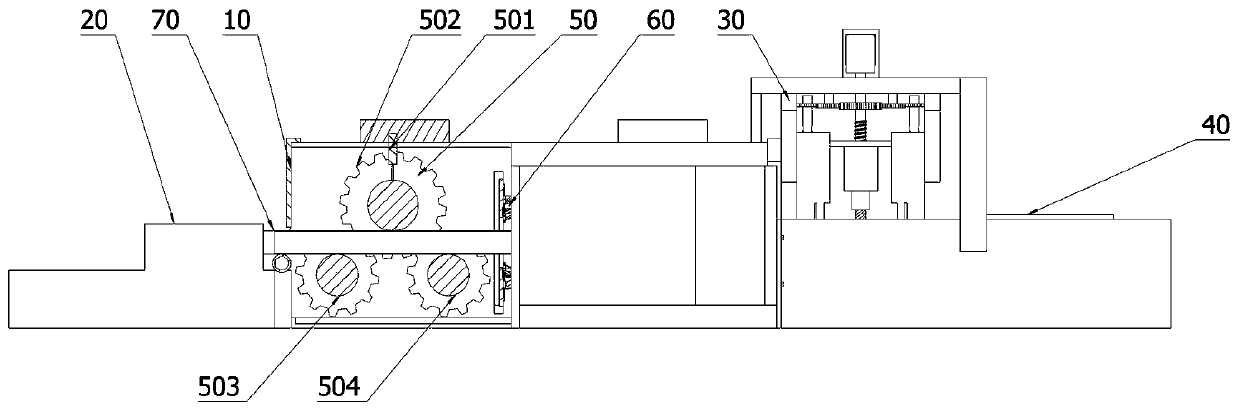

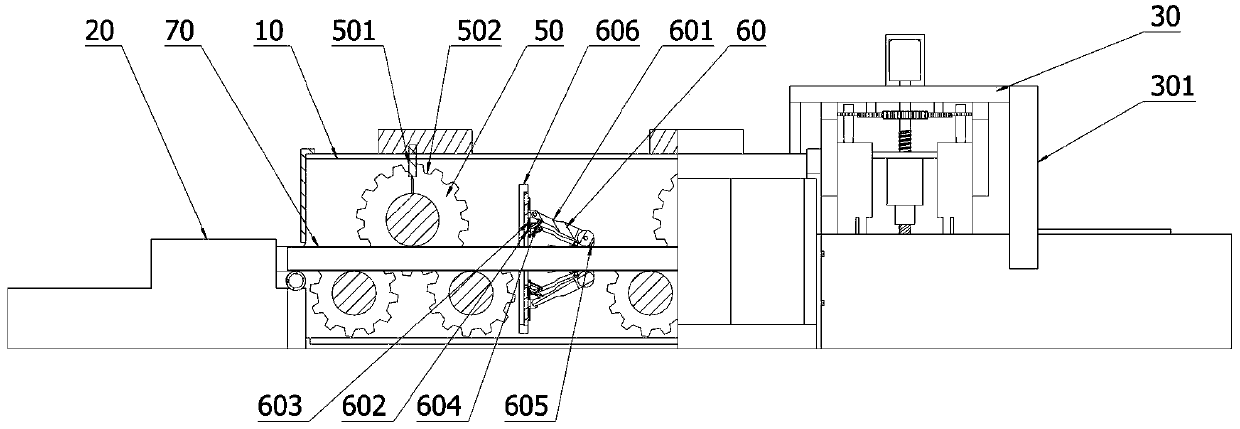

[0048] Such as figure 1 , 2 As shown, this embodiment discloses a steel pipe 70 straightening and processing device, including: a machine body 10, a straightening device 50, a pressure wheel 502, a cleaning brush 501, a first squeezing wheel 503, a second squeezing wheel 504, and a detection device 60. Drilling device 30, discharging device 40, the body 10 is arranged on a plane, and one side of the body 10 is provided with a feeding port 20, and the feeding port 20 is integrally formed with the body 10; the straightening device 50 is arranged inside the body 10, The straightening device 50 is fixedly connected with the body 10, the straightening device 50 includes: a pressure wheel 502 is arranged inside the body 10, the pressure wheel 502 is movably connected with the inner wall of the body 10, the outer periphery of the pressure wheel 502 is provided with a semicircular groove, The semicircular groove of the pressure wheel 502 is not flush with the feeding port 20; the cle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com