Adjustable hanger suitable for hanging panels with different thicknesses in up-down direction

A technology with different thicknesses and pendants, applied in covering/lining, construction, building construction, etc., can solve problems such as difficult repairs, stuck T-shaped pendants, pendants that cannot be adjusted independently, etc., to achieve the effect of replacement and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

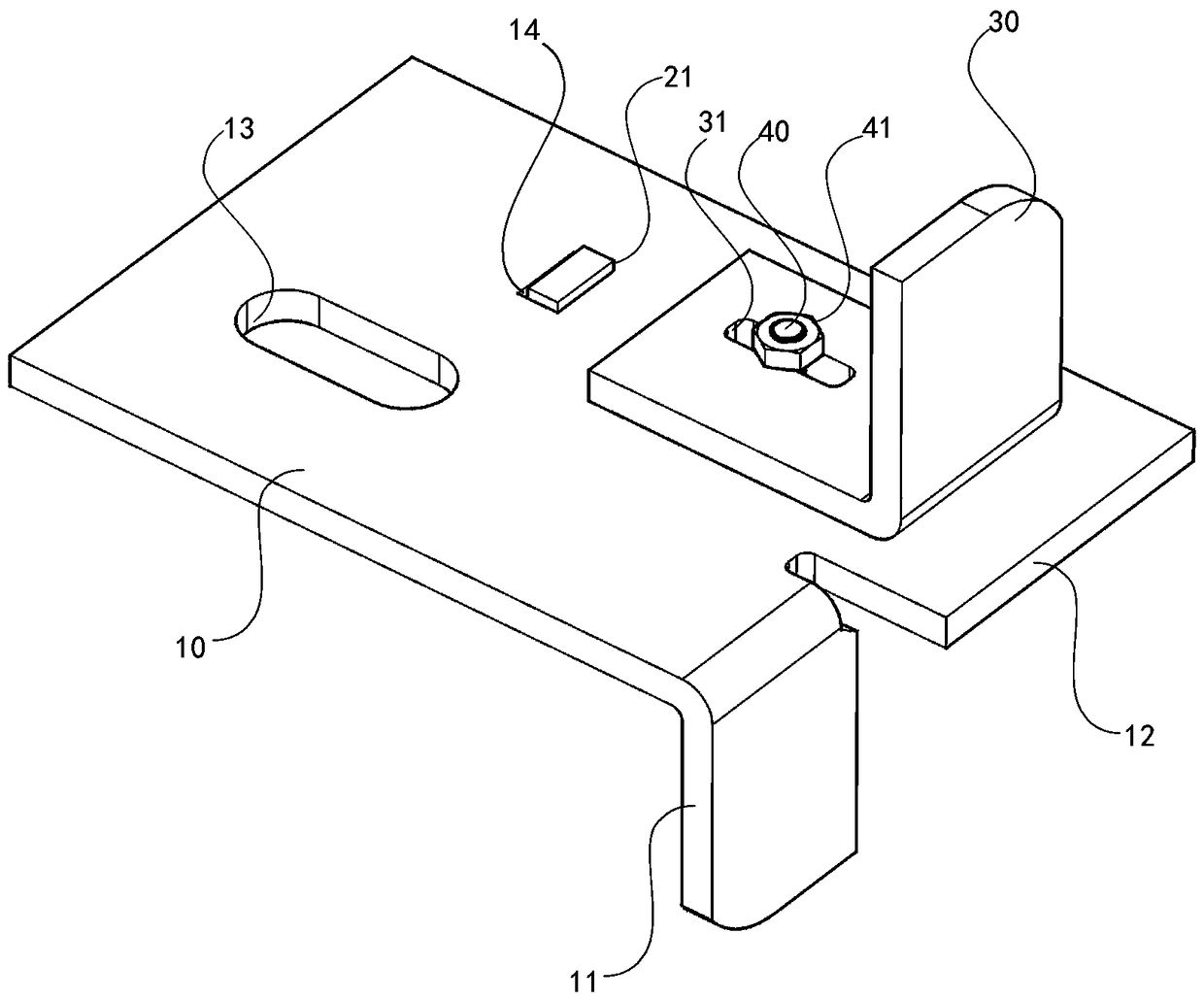

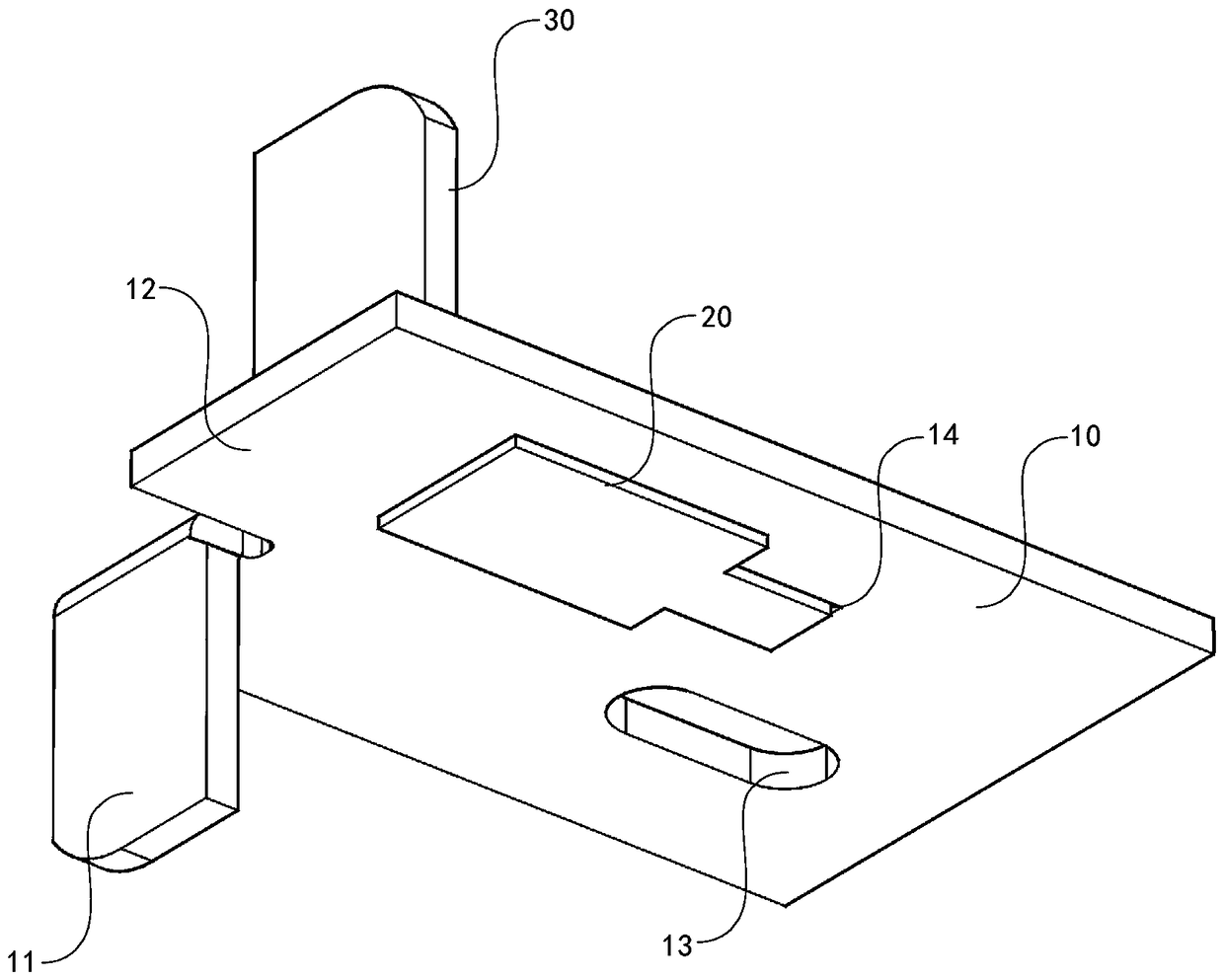

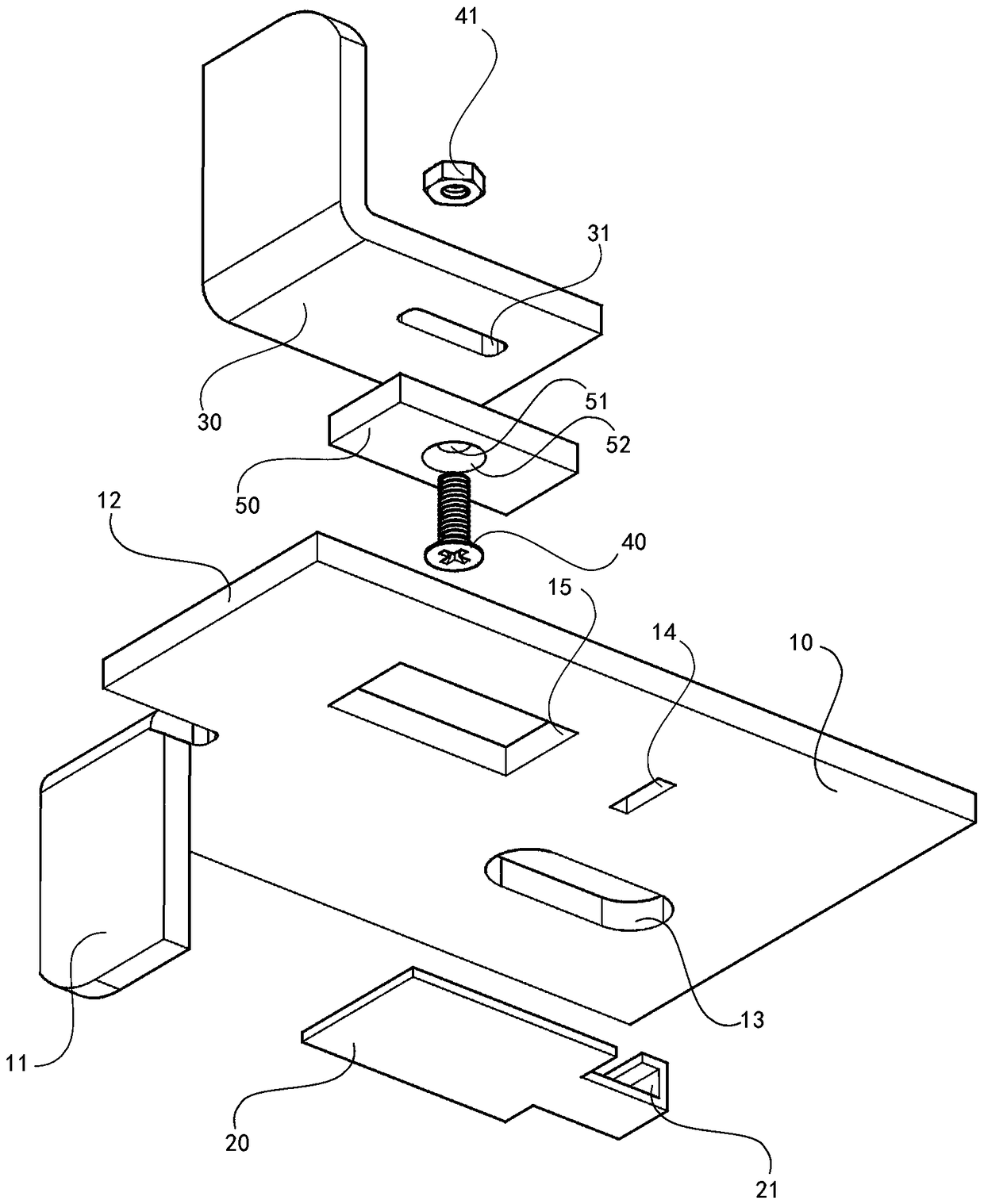

[0016] Below, the present invention will be further described in conjunction with accompanying drawing and embodiment: Figure 1 to Figure 4 As shown, an adjustable pendant suitable for hanging panels with different thicknesses up and down, including a pendant main body 10, a pro-magnet piece 20, an upward hook head 30, a screw 40, and a magnet block 50; it is characterized in that the pendant main body 10 It is provided with a downward hook 11, a load-bearing protrusion 12, a main body positioning adjustment hole 13, a small through hole 14, and a large through hole 15; It is fixed under the large through hole 15 of the main body 10 of the pendant; the upward hook head 30 is in the shape of a corner block, and a positioning slot 31 is provided on one lateral side; the screw 40 passes through the round hole 51 provided on the magnet block 50 and the positioning Groove 31 and nut 41 are screwed together, and magnet block 50 is fixed on the below of upward hook head 30, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com