Fixing device and installation method of transverse profiled plate

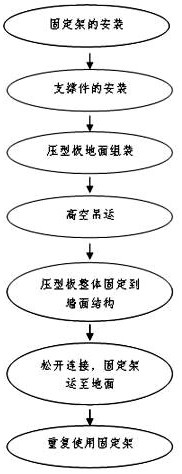

A technology of fixing device and profiled plate, which is applied in the processing of building materials, construction, building structure, etc., can solve the problems of scattered installation of horizontal metal profiled plates, improve installation efficiency and installation quality, meet engineering needs and Development trend, the effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

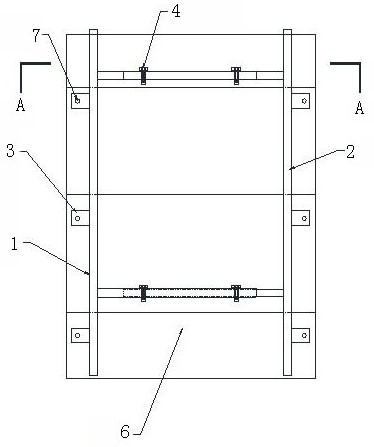

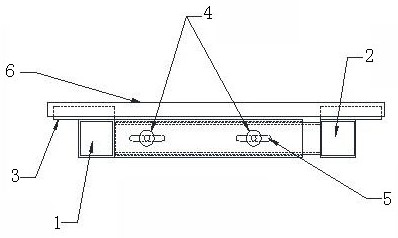

[0021] Such as figure 1 , 2 Shown: a fixing device for a horizontal profiled plate, which includes two fixing frames, support members 3, and adjusting bolts 4, the fixing frame includes a vertical bar and a horizontal tube arranged on one side of the vertical bar, the first The fixed frame 1 and the second fixed frame 2 are placed oppositely, and the horizontal tubes are located on the inner side, wherein the diameter of the horizontal tube of the first fixed frame is larger than that of the second fixed frame, and the horizontal tube of the first fixed frame is sleeved on the second fixed frame Outside the horizontal tubes of the two horizontal tubes, oblong holes 5 are provided on the two horizontal tubes and fixed by adjusting bolts; the outer sides of the vertical rods of the first fixed frame and the second fixed frame are respectively provided with a number of supports at intervals, and the supports are provided with preset Leave holes 7.

[0022] Further, the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com