Wheel rail type drilling pipe storage device

A storage device, wheel-rail technology, applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of low degree of automation of drill pipe handling operations, large floor area occupied by the ground drill pipe discharge system, and high operational safety risks , to achieve the effects of easy towing and moving at the well site, large storage capacity of drill pipes, and high moving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

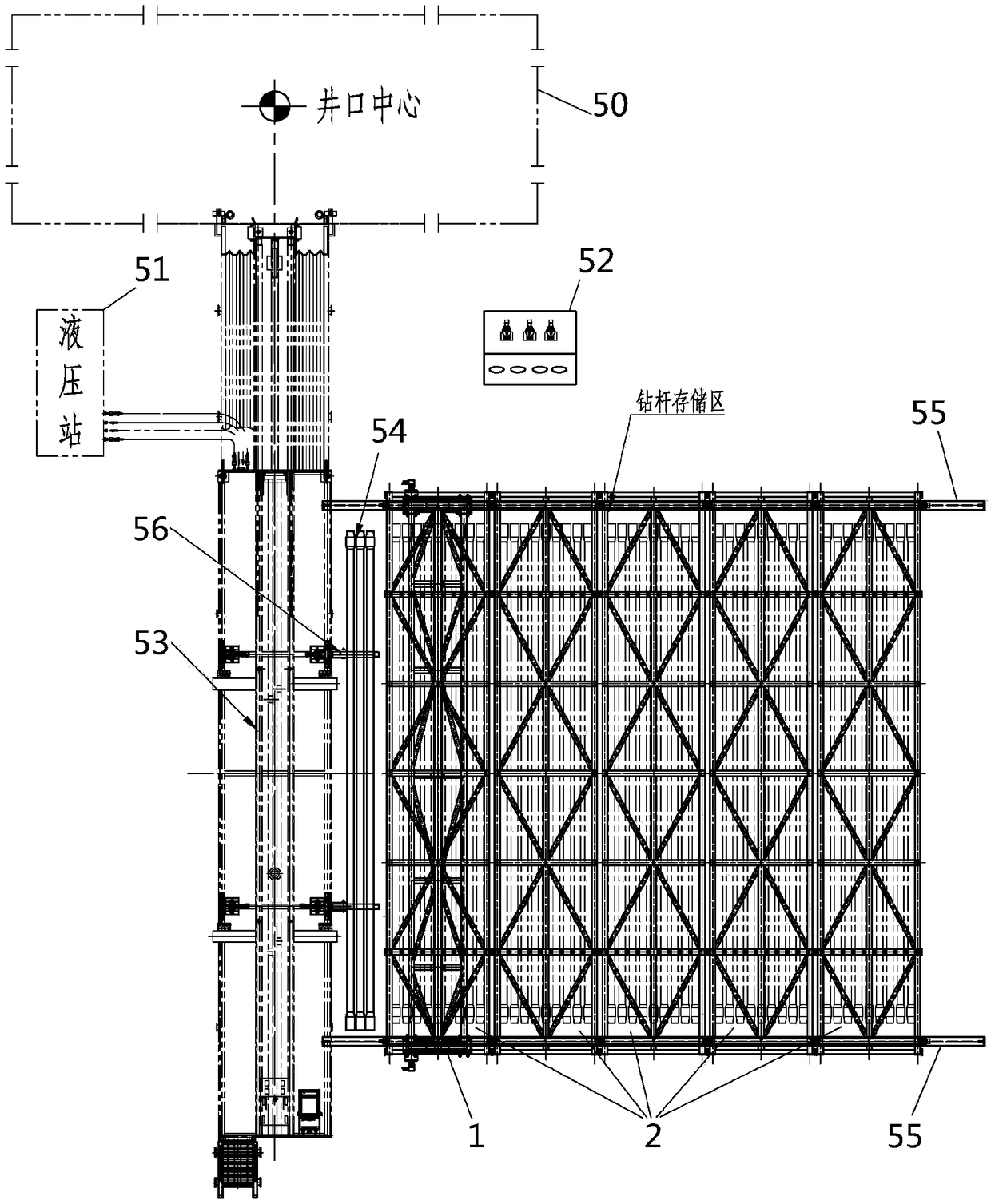

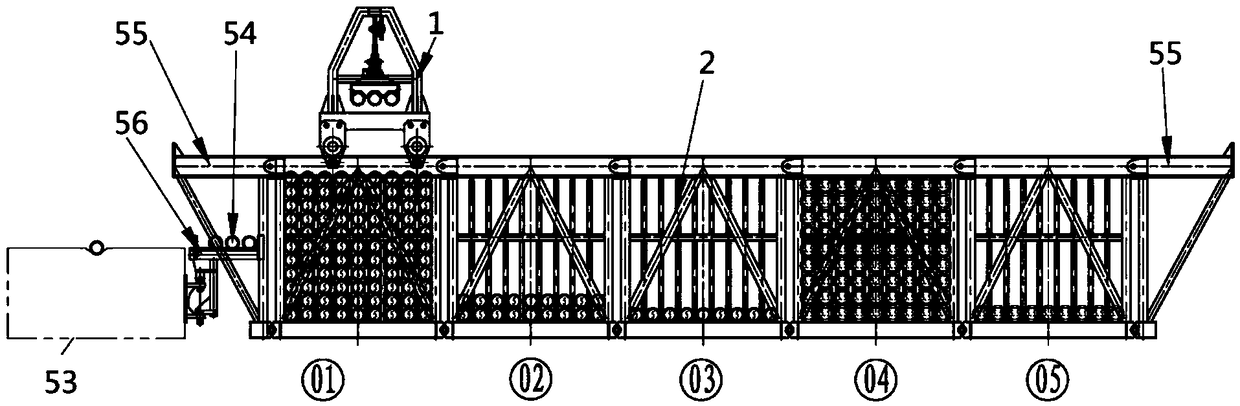

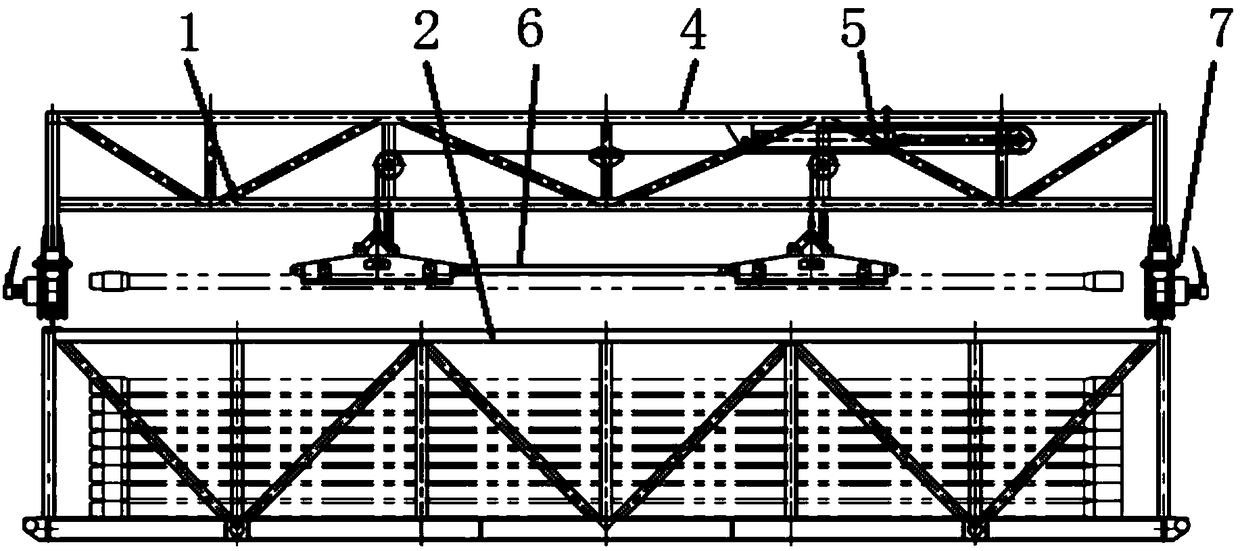

[0052] refer to Figure 1a , Figure 1b The structure of the present invention is to include several sets of drill rod storage racks 2 that are connected side by side vertically. A pair of extended guide rails 55 that are connected horizontally are arranged on the upper surface of the longitudinal ends of the drill rod storage rack 2. The two ends of the pair of extended guide rails 55 grow out of the On the outer edges of the drill pipe storage rack 2 in the transverse direction, a drill pipe conveying mechanism 1 is arranged on the pair of extended guide rails 55; the main body of the drill pipe conveying mechanism 1 is the drill pipe conveying frame 4, and the lower edges of the drill pipe conveying frame 4 are respectively A roller unit 7 is provided, and the drill pipe conveying frame 4 slides along the extended guide rail 55 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com