Automatic shaft type detection method

An automatic detection and shaft type technology, which is applied in the direction of mechanical bearing testing, measuring devices, instruments, etc., can solve the problems that small motor shafts cannot be detected, cannot detect whether all shafts have reached the specified position, and detect unfavorable positions. Not easily affected by external environment, reliable detection method and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

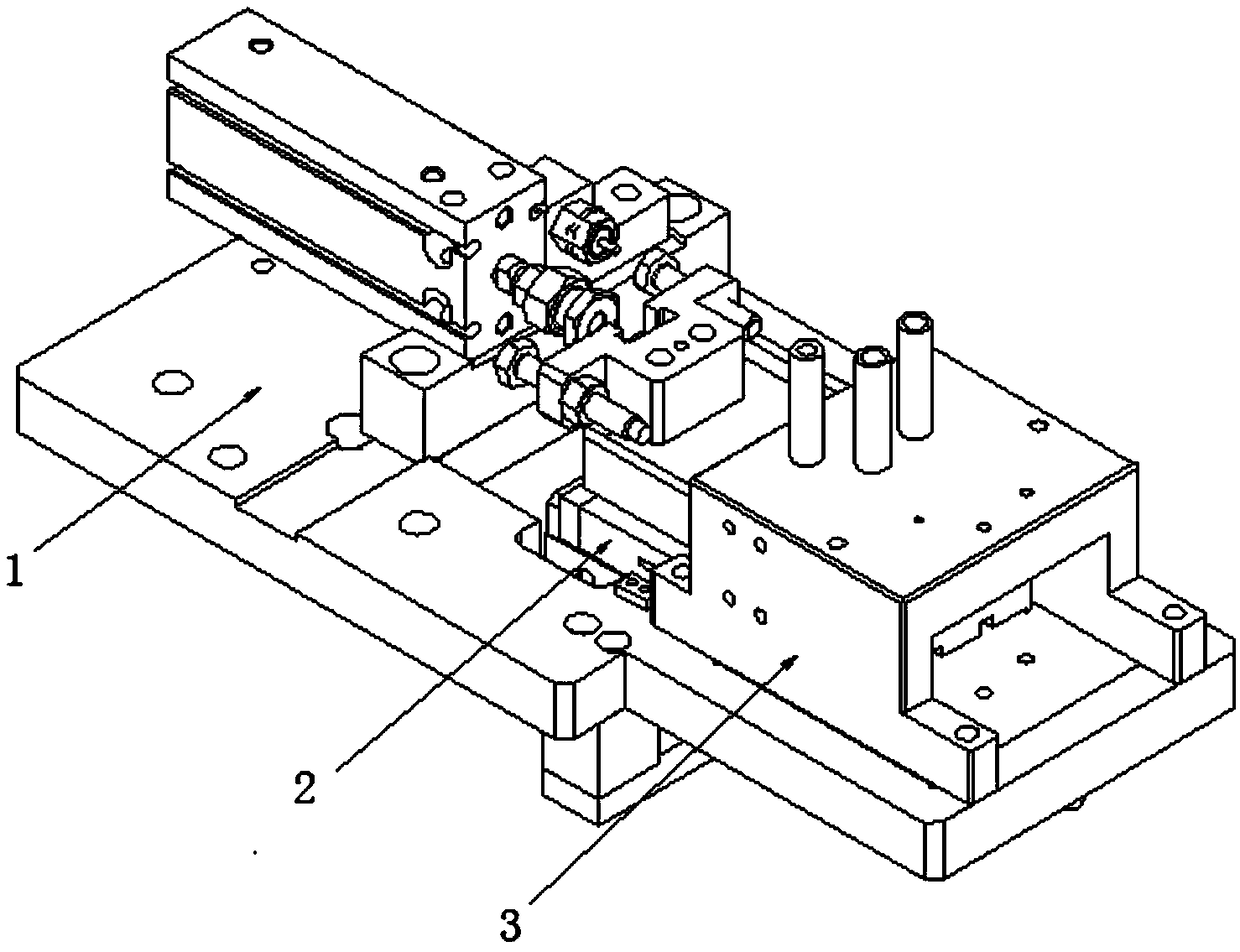

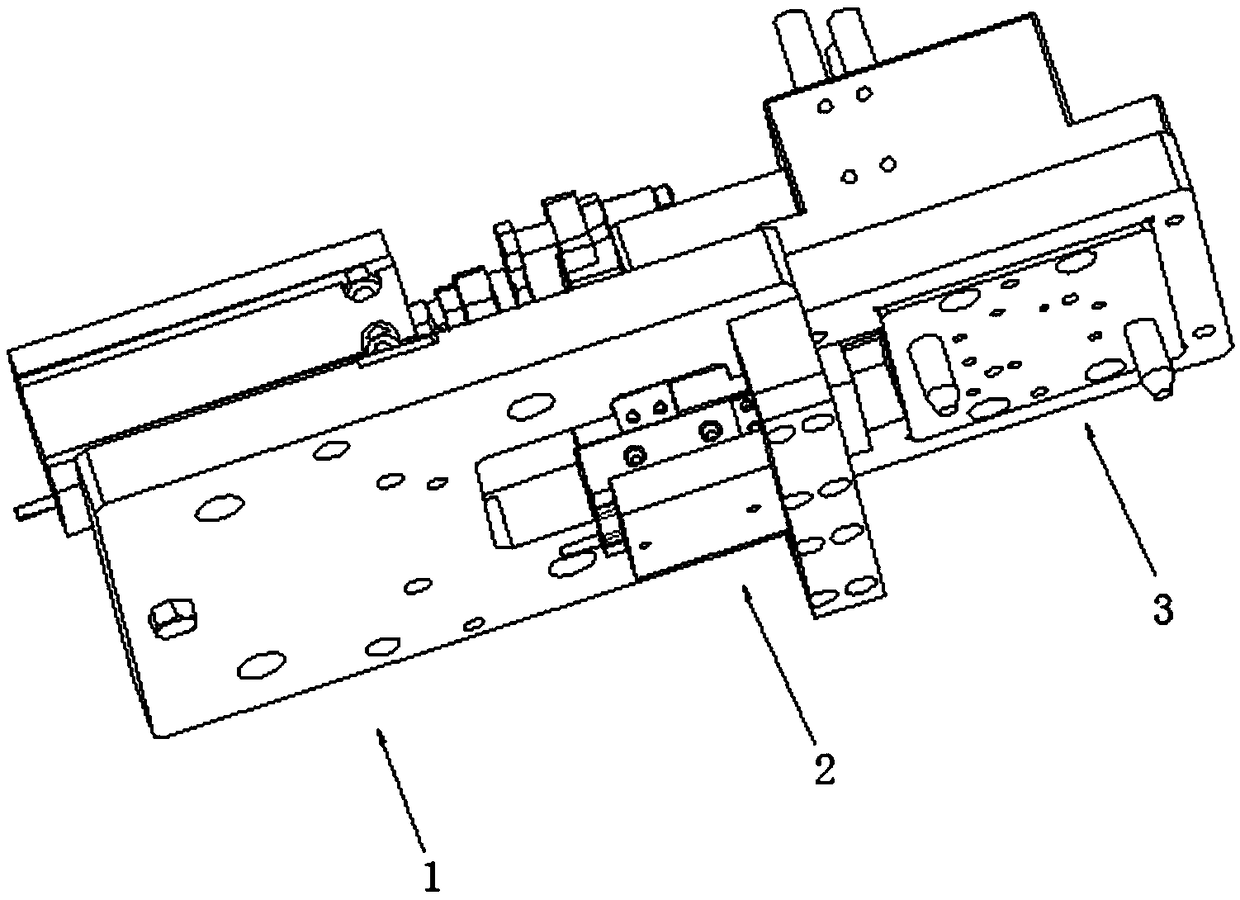

[0050] Such as Figure 1 to Figure 7 As shown, a shaft automatic detection mechanism includes a guide assembly 3 and a detection assembly 2 .

[0051] The guide assembly 3 includes a first guide plate 31 and a push plate 32, the first guide plate 31 is provided with a plurality of first guide holes 311, the push plate 32 is arranged on the first guide plate 31, and the first guide holes 311, and the position corresponding to the first guide hole 311 on the push plate 32 is provided with a detection through hole 321, and the detection through hole 321 is coaxial with the first guide hole 311 and corresponds one by one, so that the shaft type The component enters the corresponding detection through hole 321 through the first guide hole 311 . When the push plate 32 is in the initial state, the first guide hole 311 on the first guide plate 31 is coaxial with the detection through hole 321 on the push plate 32, and the shaft (such as a small motor shaft) passes through the first g...

Embodiment 2

[0057] In this embodiment 2, on the basis of the embodiment 1, the structure of the detection assembly 2 is further optimized, so that all shafts in the detection through hole can be accurately detected.

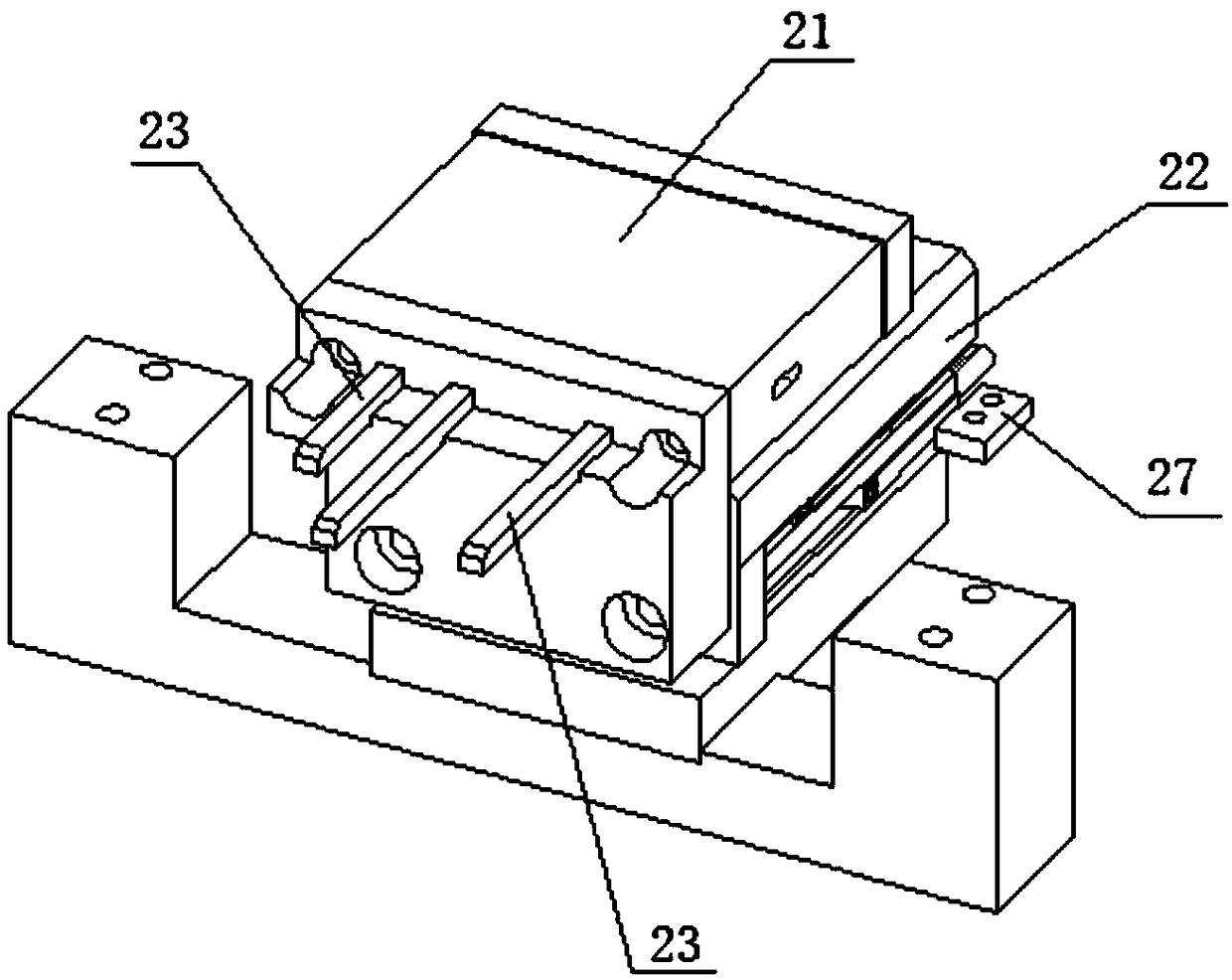

[0058] Such as Figure 3 to Figure 4 , Figure 8 to Figure 9 As shown, the detection assembly 2 also includes a guide pin mounting block 21 , a spring cover plate, and a sliding platform connecting plate 26 .

[0059] The guide pin installation block 21 is provided with a guide pin installation hole 211 , and the guide pin installation hole 211 is used for accommodating the detection needle 23 and providing space for the detection needle 23 to slide back and forth. The detection pin 23 is slidably inserted into the guide pin installation hole 211 . The guide pin mounting block 21 is assembled on the slide table 22 through the slide table connecting plate 26 . The slide table 22 can use a slide table cylinder as a power source for the detection needle 23 . The slide table...

Embodiment 3

[0067] On the basis of Embodiment 2, in order to automatically drive the shaft parts in the push plate 32 to carry out precise assembly, as Figure 1 to Figure 14 As shown, in the present embodiment 3, the shaft automatic detection mechanism also includes a push assembly 1, and the push assembly 1 includes a cylinder 11 and a cylinder push block 13, and the cylinder push block 13 is fixedly connected to the piston rod of the cylinder 11, and the cylinder push block 13 is also fixedly connected with the push plate 32 of the guide assembly, and the push plate 32 is slidably assembled on the first guide plate 31 so that the cylinder 11 pushes the push plate 32 to slide back and forth along the first guide plate 31 . The cylinder provides power for the sliding of the push plate 32 along the first guide plate 31. The piston rod of the cylinder 11 is equipped with a cylinder push block 13, which indirectly drives the push plate 32 to move through the connection between the cylinder p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com