A method for measuring the spectral reflectance of a full-scale object surface

A technology of spectral reflectance and object surface, which is applied in the field of photoelectric detection, can solve the problems that are not suitable for testing the spectral reflectance of the surface of high reflectivity objects, and test the error of samples with low reflectivity, so as to achieve convenient and fast operation and small error of test data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

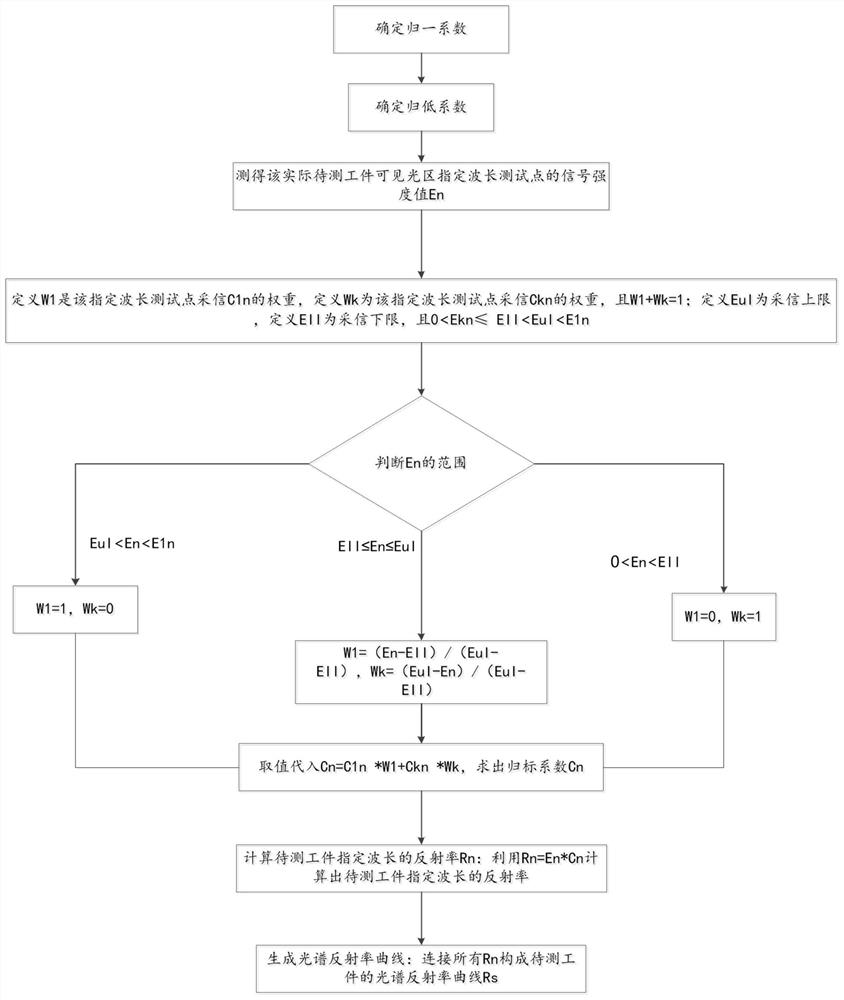

[0040] see figure 1 and figure 2 , the present invention provides a method for testing the spectral reflectance of a full-scale object surface, the method includes the following steps:

[0041] S1: Determine the normalization coefficient: place the 100% reflectance calibration reference sheet on the spectrometer carrier, measure the signal intensity value E1n of the specified wavelength test point in the visible light region of the reference sheet, and calculate the normalization coefficient according to E1n C1n;

[0042] S2: Determine the reduction coefficient: place the low-reflectivity calibration reference sheet on the spectrometer's carrier, measure the signal intensity value of the specified wavelength test point in the visible region of the reference sheet as Ekn, and calculate the reduction coefficient Ckn according to Ekn ;

[0043] S3: Measure the signal strength of the test point at the specified wavelength in the actual visible light region of the workpiece: p...

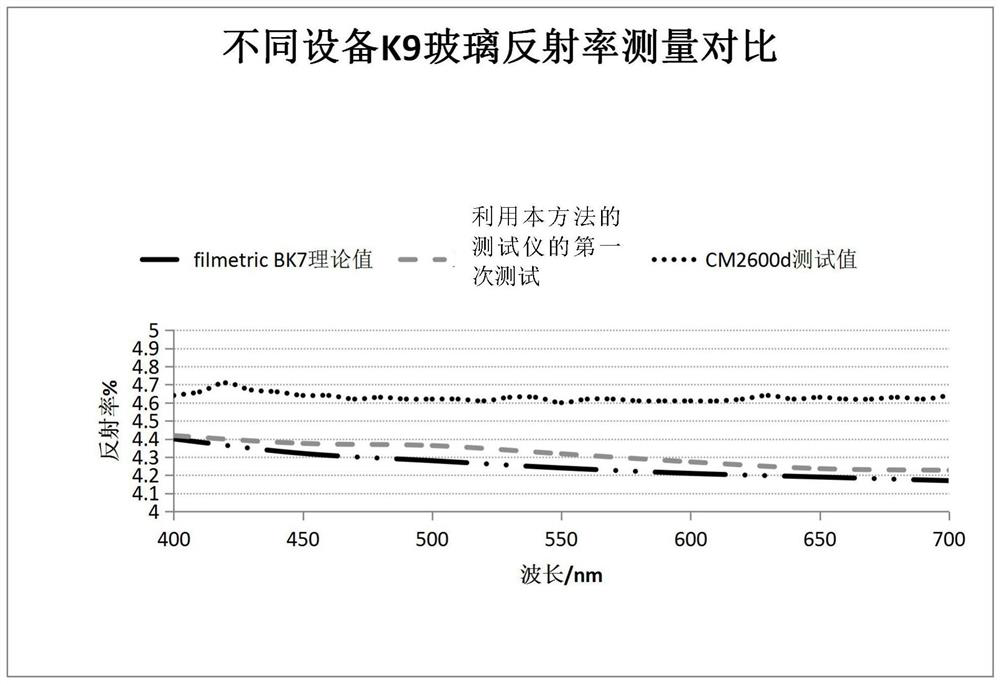

specific Embodiment 2

[0063] see figure 1 and image 3 , the present invention provides a method for testing the spectral reflectance of a full-scale object surface, the method includes the following steps:

[0064] S1: Determine the normalization coefficient: place the 100% reflectance calibration reference sheet on the spectrometer carrier, measure the signal intensity value E1n of the specified wavelength test point in the visible light region of the reference sheet, and calculate the normalization coefficient according to E1n C1n;

[0065] S2: Determine the reduction coefficient: place the low-reflectivity calibration reference sheet on the spectrometer's carrier, measure the signal intensity value of the specified wavelength test point in the visible region of the reference sheet as Ekn, and calculate the reduction coefficient Ckn according to Ekn ;

[0066] S3: Measure the signal strength of the test point at the specified wavelength in the actual visible light region of the workpiece: pl...

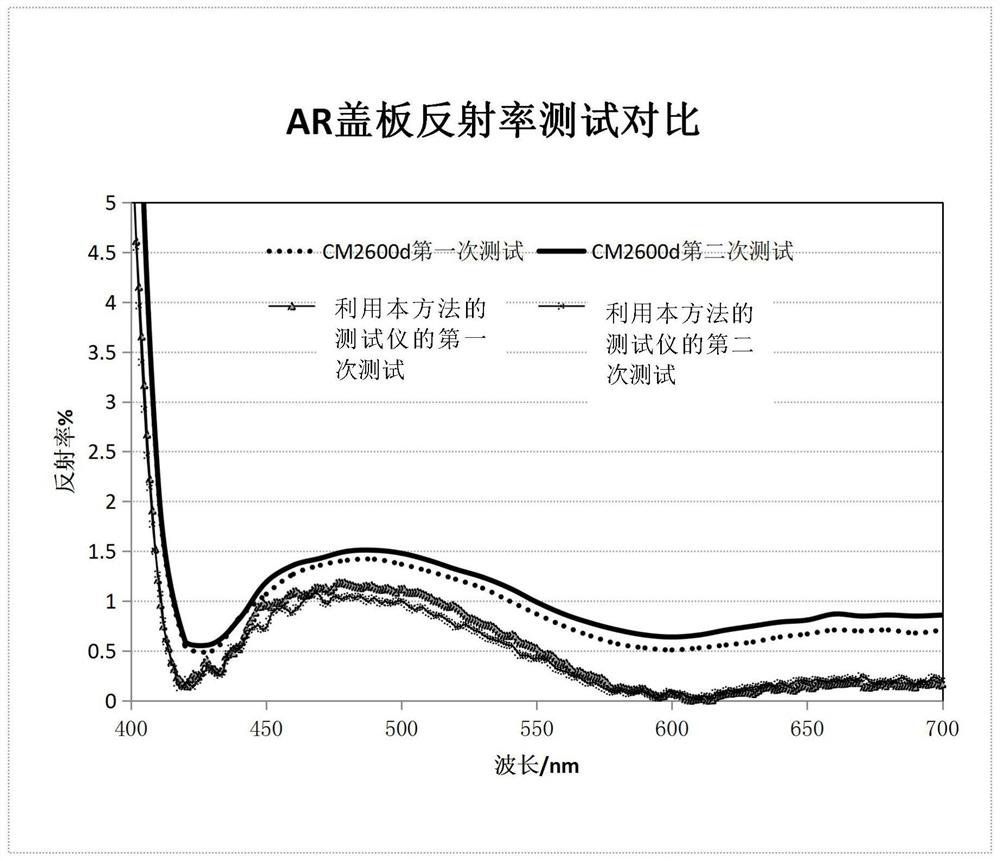

specific Embodiment 3

[0086] see figure 1 and Figure 4 , the present invention provides a method for testing the spectral reflectance of a full-scale object surface, the method includes the following steps:

[0087] S1: Determine the normalization coefficient: place the 100% reflectance calibration reference sheet on the spectrometer carrier, measure the signal intensity value E1n of the specified wavelength test point in the visible light region of the reference sheet, and calculate the normalization coefficient according to E1n C1n;

[0088] S2: Determine the reduction coefficient: place the low-reflectivity calibration reference sheet on the spectrometer's carrier, measure the signal intensity value of the specified wavelength test point in the visible region of the reference sheet as Ekn, and calculate the reduction coefficient Ckn according to Ekn ;

[0089] S3: Measure the signal strength of the test point at the specified wavelength in the actual visible light region of the workpiece: p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com