A Universal Axle Automatic Test Bench

An automatic test and general-purpose technology, which is applied in the direction of vehicle testing, mechanical component testing, machine/structural component testing, etc., can solve the problems of inability to truly simulate the loading attitude of the axle, cumbersome translational screw drive, and maintenance costs High-level problems, to achieve the effect of saving raw materials, wide range of use, and low maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

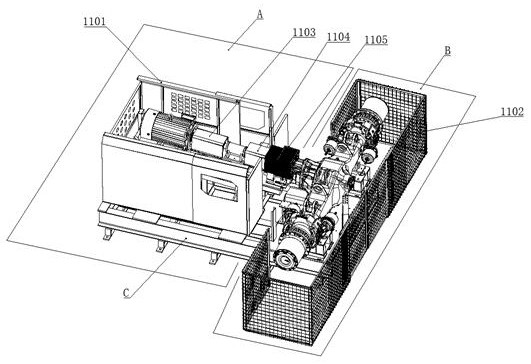

[0055] Such as figure 1 As shown, the general-purpose axle automatic test bench includes a bench C, and above the bench C are an axle placement area B and a test transmission area A, and the axle placement area B is located on the side of the test transmission area A.

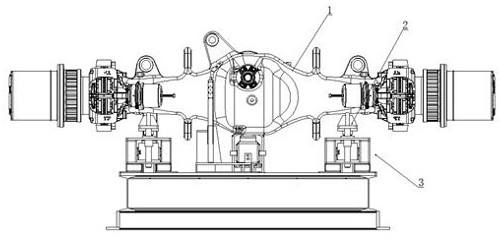

[0056] Such as figure 2 As shown, the axle placement area B includes the bridge strut 2 and the bridge lifting assembly 3 for placing the axle 1, and the bridge strut 2 is driven by the bridge lifting assembly 3 to move up and down.

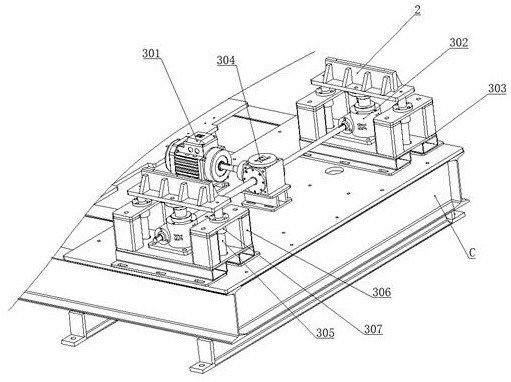

[0057] Such as Figure 4 As shown, the test transmission area A includes a running motor 4, a transmission shaft system 5, an adjustment base plate 6, a rear-end lifting adjustment mechanism 7 and an automatic docking assembly 8, and the adjustment base plate 6 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com