Sliding mode control method and control device for tension of tension roll strip steel

A control method and tension control technology, applied in the direction of mechanical pressure/force control, adaptive control, general control system, etc., can solve the problems of unsatisfactory control effect and low control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

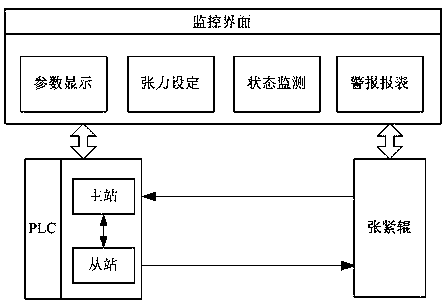

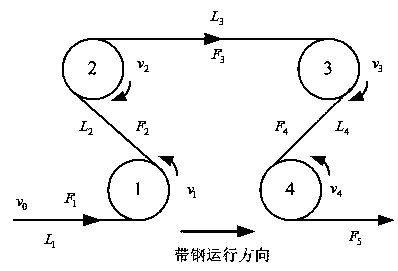

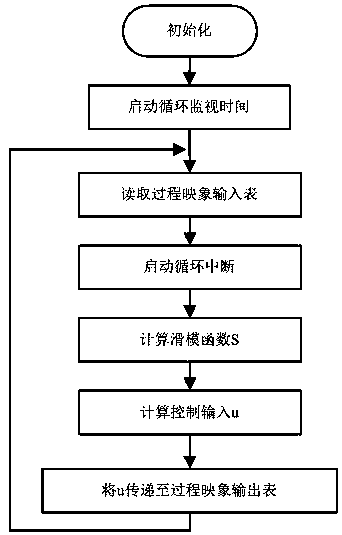

[0074] Such as Figure 1-3 Shown, the sliding mode control method of a kind of tension roller strip steel tension of the present invention comprises the following steps:

[0075] Step 1. Tension roller strip tension modeling

[0076] (1) tension roller structure

[0077] The invention establishes a tension roller strip steel tension control model by taking a 4-axis tension roller composed of 4 driving rollers as an example. According to the order in which the steel strip passes through each roller, each drive roller is defined as No. 1, No. 2, No. 3, and No. 4. Among them, No. 1 roller and No. 4 roller rotate counterclockwise, No. 2 roller and No. 3 roller rotate clockwise, v 0 is the upstream strip speed of the tension roll, v 1 , v 2 , v 3 , v 4 are the rotational linear speeds of each drive roller, respectively. Among them, v 0 The size of vi is determined by the upstream production process and can be detected by measuring tools, which is a known parameter; the siz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com