A wafer fixing device and a wafer labeling apparatus for an integrated circuit

A wafer fixing and integrated circuit technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of low processing efficiency and yield, low automation rate of label pasting, inconvenient clamping and positioning, etc., to achieve processing High efficiency and processing yield, easy to replace label information, and increase the effect of processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

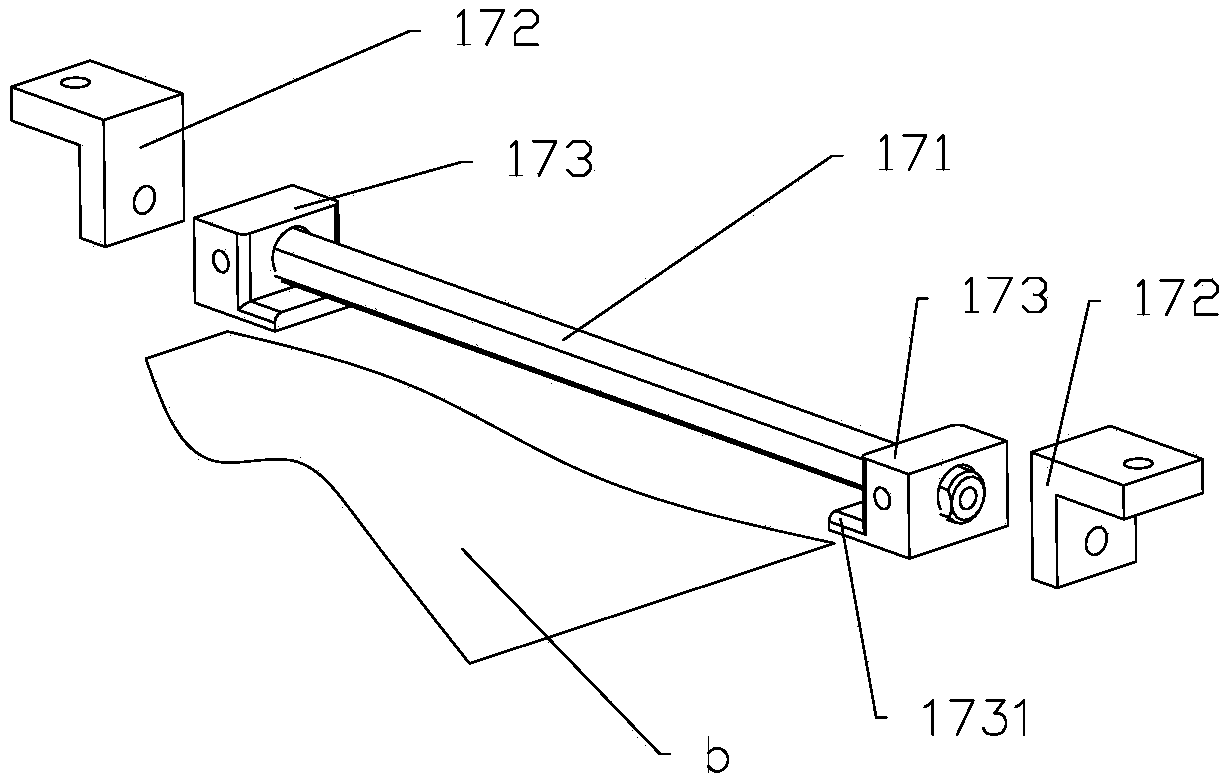

[0025] Such as Figure 7 , Figure 8 and Figure 9 The wafer fixing device shown includes a wafer adsorption mechanism 41 and a wafer stage mechanism 42; the wafer stage mechanism 42 is used to accept processed wafers, and its size can be adjusted to adapt to wafers of different sizes; The circular adsorption mechanism 41 is located at the center of the wafer stage mechanism 42, and is used to absorb the wafer fixed on the wafer stage mechanism 42, so as to ensure the stability during processing. The wafer fixture can be moved and fixed, which is convenient for wafer loading and unloading and labeling.

[0026] The wafer adsorption mechanism 41 includes a circular suction cup 411, a cylindrical optical shaft 412, a mounting plate 413, and a second cylinder 414; the cylindrical optical shaft 412 is fixed on the bottom of the circular suction cup 411, and the cylindrical optical shaft 412 is connected to the On the mounting plate 413, the circular suction cup 411 is provided ...

Embodiment 2

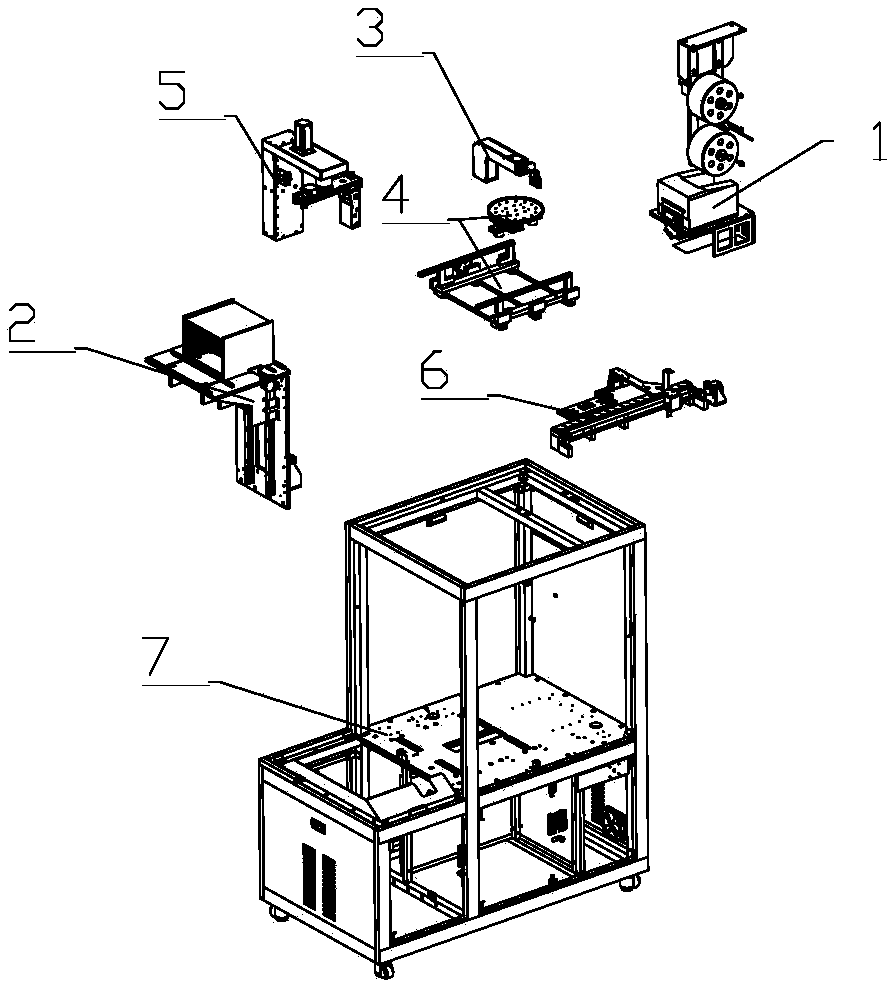

[0030] Such as Figure 1-Figure 11 The wafer labeling equipment for integrated circuits shown includes a frame 7 and a label feeding and discharging device 1 on it, a wafer feeding and discharging device 2, a label moving device 3, a wafer fixing device 4, a labeling detection device 5 and Wafer transfer device 6.

[0031] The wafer feeding and discharging device 2 is connected with the wafer fixing device 4 through the label moving device 3, and the wafer fixing device 4 is connected with the wafer feeding and discharging device 2. The labeling detection device 5 is located directly above the wafer fixing device 4. The position of the circular transfer device 6 corresponds to the wafer feeding and unloading device 2 and the wafer fixing device 4 .

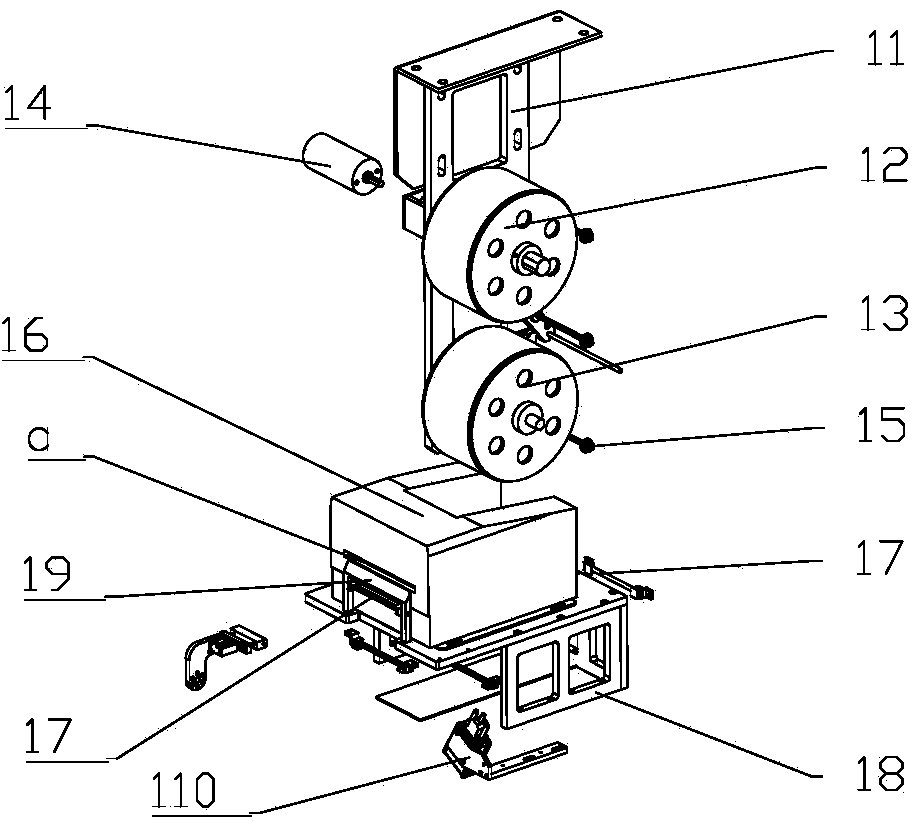

[0032] The label feeding and discharging device 1 is used for blank label feeding, label spraying and recycling of waste paper. The wafer feeding and unloading device 2 is used for loading wafers to be labeled and unloading fini...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com