Liquid injection method for a carbon fiber storage battery

A storage battery and carbon fiber technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems of high density and difficulty in fully absorbing electrolyte, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

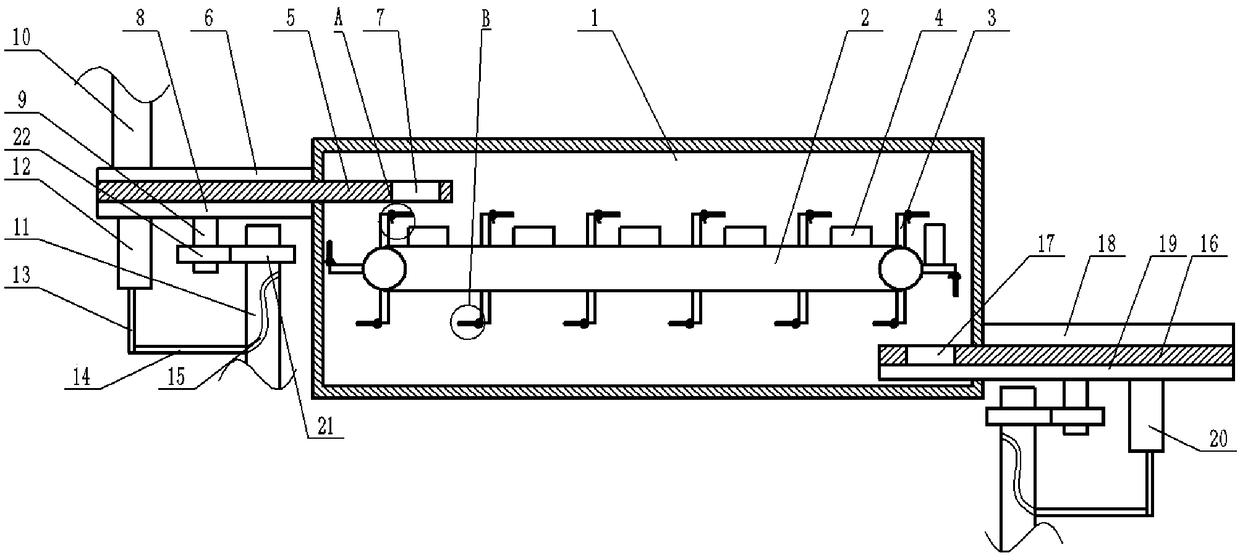

[0029] The continuous carbon fiber battery liquid injection equipment used in the liquid injection method of carbon fiber battery, such as figure 1 As shown, it includes a frame on which a vacuum tank 1 is fixed, and a transmission mechanism for transmitting batteries 4 is arranged in the vacuum tank 1. The transmission mechanism includes a conveyor belt 2, and a plurality of partitions 3 are evenly distributed on the conveyor belt 2 along the transmission direction. Placement cavities are formed between adjacent partitions 3 .

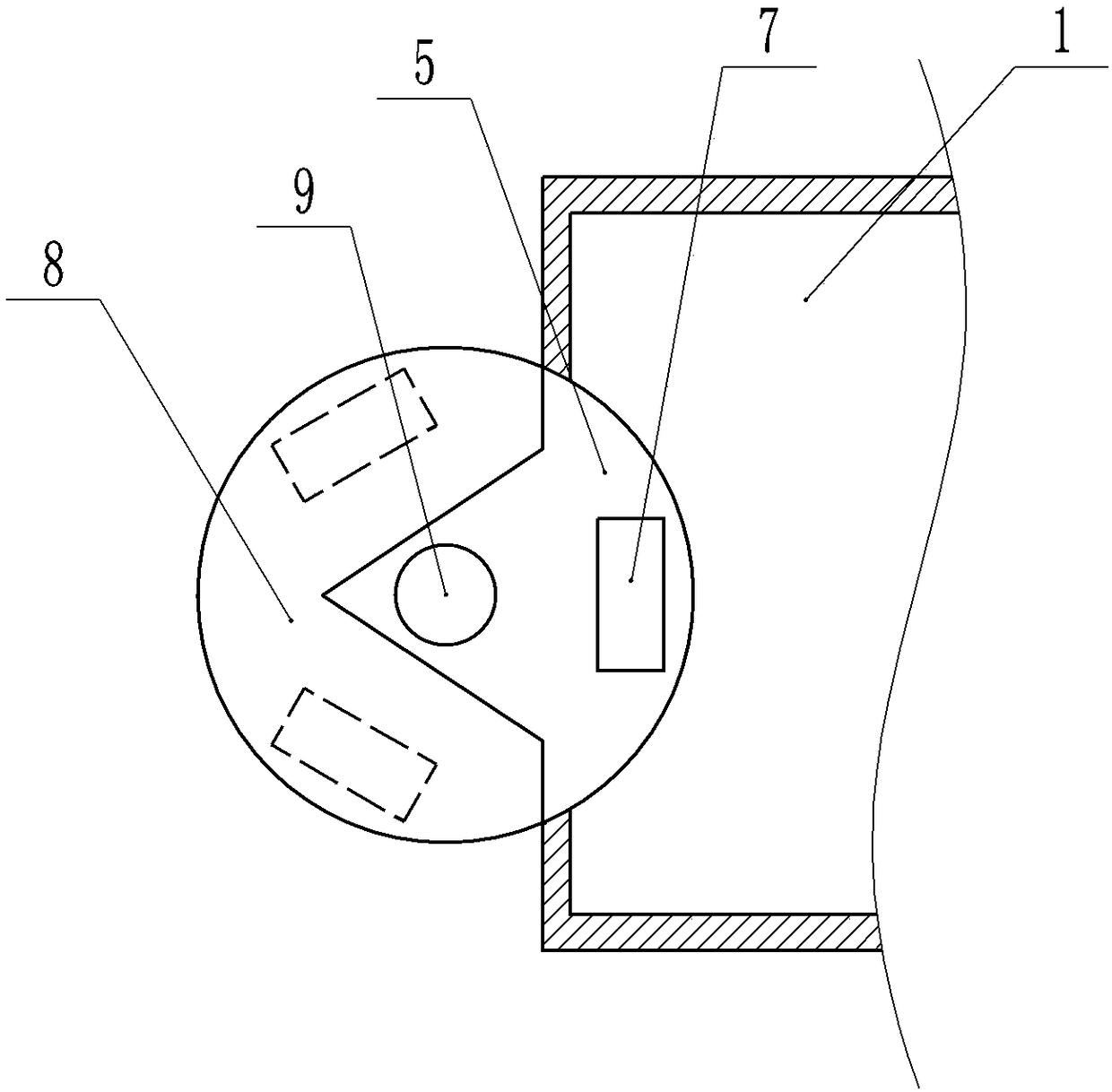

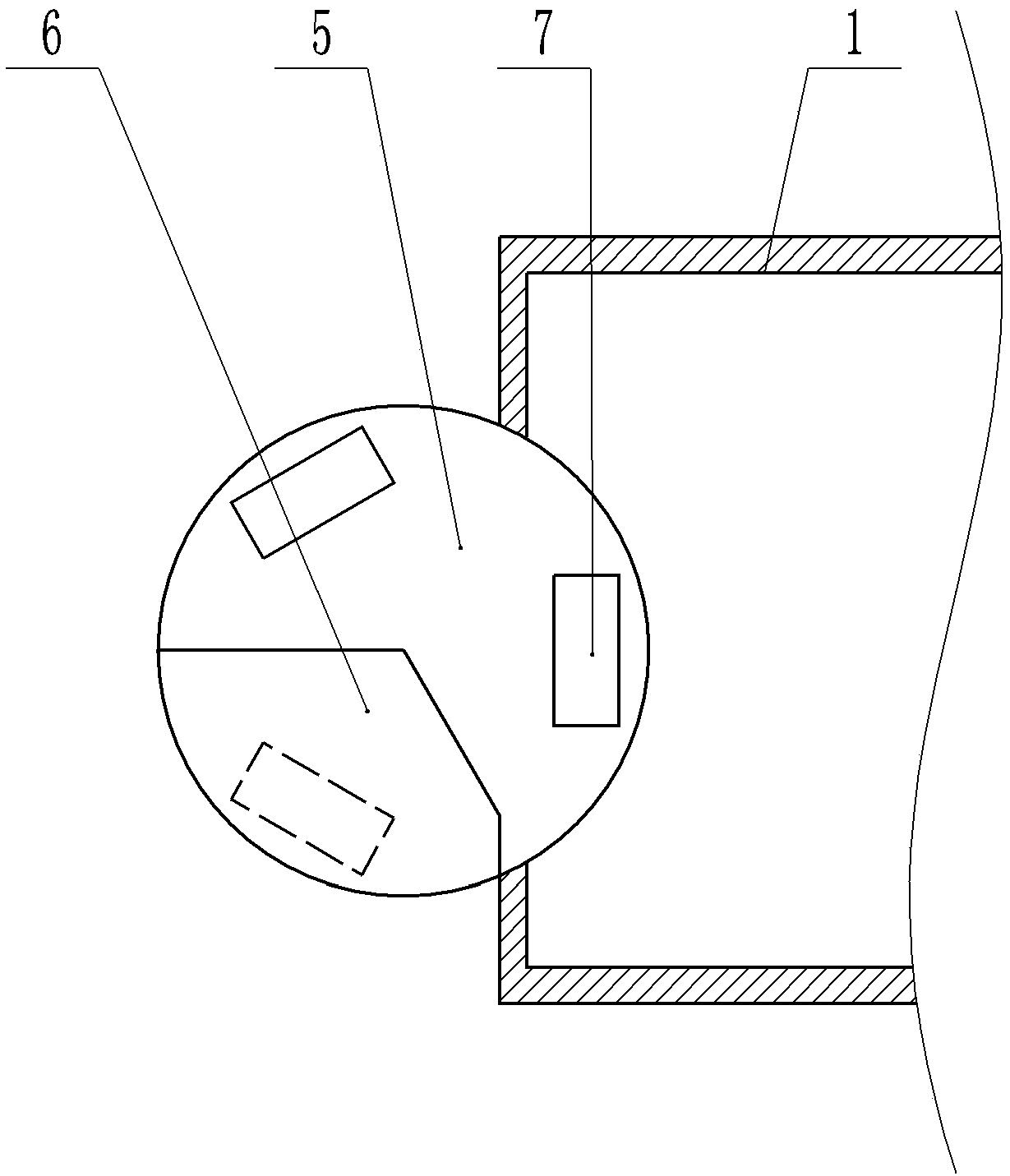

[0030] combine figure 2 , image 3 As shown, a feeding mechanism is arranged above the left end of the transmission mechanism on the frame. The feeding mechanism includes a first turntable 5 that is rotatably connected to the frame. area, the feeding area includes a first through hole 7 arranged on the first turntable 5 , and the size of the first through hole 7 is equal to the size of the battery 4 . The right end of the first turntable 5 runs th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com