Ready-to-drink beverages with foam formed by shaking

A technology for beverages and nuts, applied in the field of food and beverages, which can solve problems such as syneresis or coagulation of unpleasant texture and mouthfeel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] Example 1: RTD Peanut Milk Beverage

[0093] Table 1 shows two non-limiting examples of RTD peanut milk beverages according to the present application.

[0094] Table 1: Exemplary RTD Peanut Milk Beverages

[0095]

Embodiment 2

[0096] Example 2: Beverage preparation

[0097] For each beverage composition as shown in Tables 1 to 5, the process steps for preparation were as follows.

[0098] The milk powder was dissolved in a tank with hot water at 60°C to 65°C and sheared for 10 minutes. The emulsifier (sodium caseinate) was added to the tank and sheared for 10 minutes. Stabilizers (gellan gum, CMC, MMC) were dry mixed with sugar, then dissolved in hot water at 70°C and subjected to high shear treatment for 15 minutes. The stabilizer solution was added to the tank and sheared for 10 minutes. The peanuts are finely ground by a stone mill to form peanut butter. Add peanut butter to jar and mix for 5 minutes. Buffer salts (sodium citrate, sodium bicarbonate) were dissolved in hot water at 80°C and added to the tank. Flavorings were added along with the rest of the sugar and water and normalized. The standardized liquid was heated to 75°C, and then a two-stage homogenization was performed, where t...

Embodiment 3

[0099] Example 3: Method for Characterizing Beverage Compositions

[0100] Foaming / Foam Stability Testing

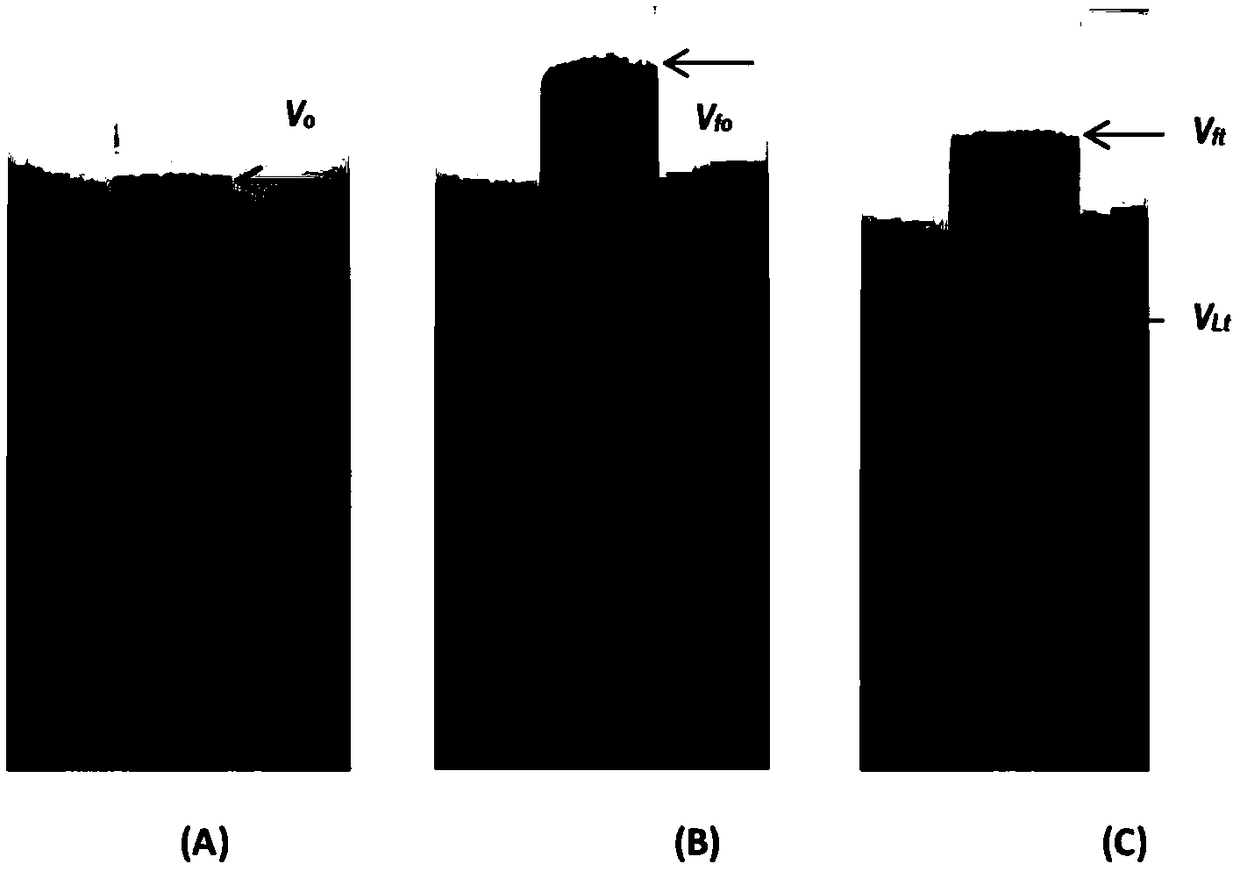

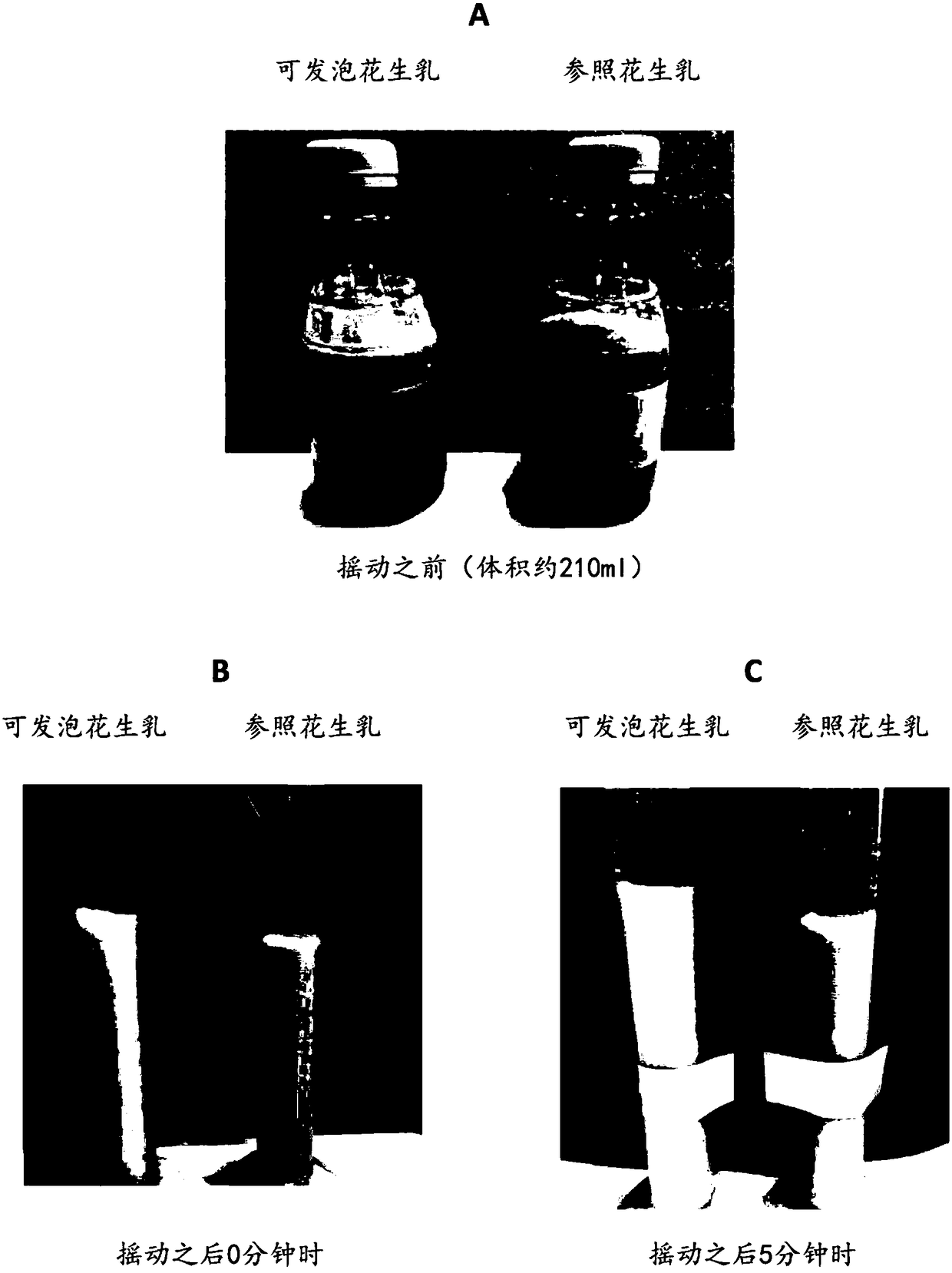

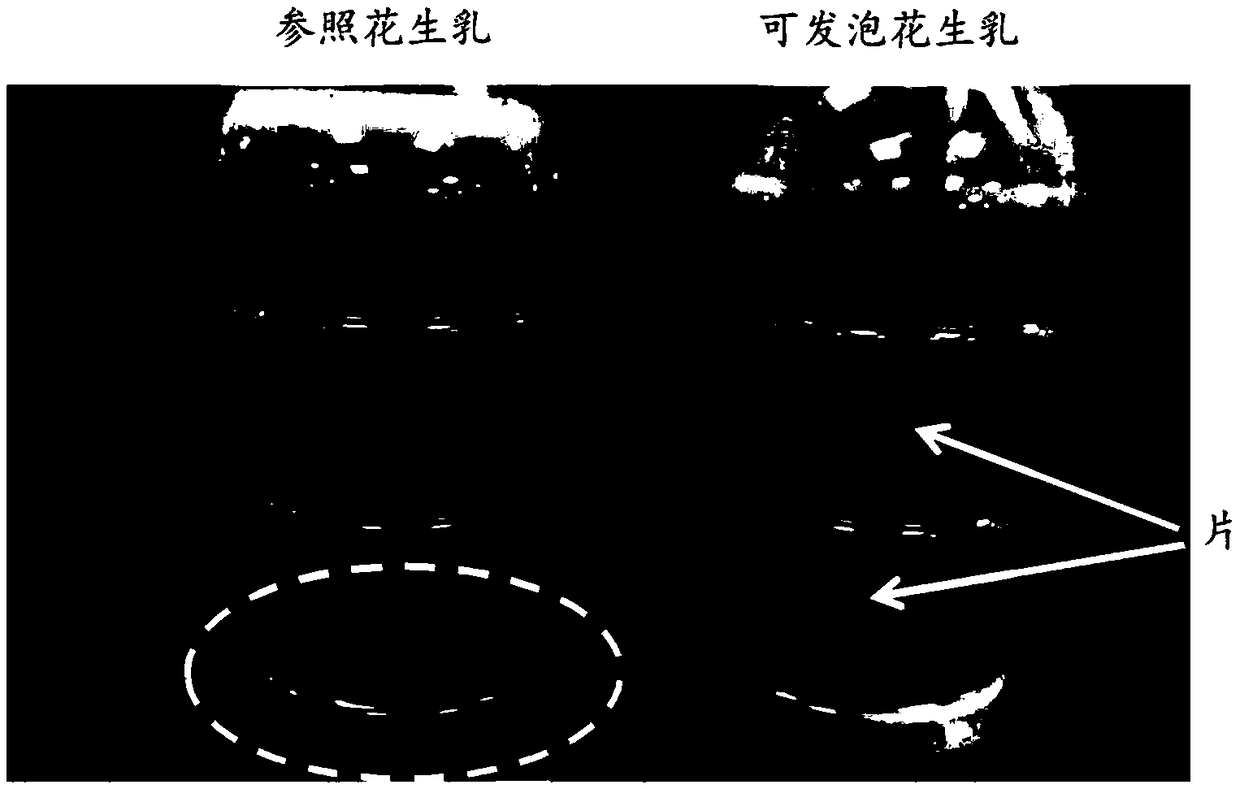

[0101] The beverages were added to 280 mL PET bottles with 30% headspace. Shake for 10 seconds at an oscillation frequency of 5 Hz. Immediately after shaking, pour the carbonated beverage into a 250ml graduated cylinder. like figure 1 As shown, the total volume of carbonated beverages (V ft ), i.e. Vf0, Vf5, Vf10, Vf15; and the volumes (VLt) of the liquid phase in the carbonated beverages, i.e., VL0, VL5, VL10, VL15, were recorded at 0, 5, 10, and 15 minutes after pouring, respectively.

[0102] Calculated as follows Foaming , expressed as a percentage of incorporated air:

[0103] Incorporated air (%)=100×(Vf0–V0) / V0 (1)

[0104] Calculated as follows foam stability (or aeration stability), expressed as the percentage of air remaining in the beverage at time t:

[0105] Inflation stability (%) = 100×(Vft–V0) / V0 (2)

[0106] Calculated as follows air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com