Aluminum alloys with enhanced formability and associated methods

A technology of aluminum alloy casting ingots and aluminum alloy products, which is applied to the combination of multiple record carriers, rigid containers, combined records, etc., can solve the problems of lack of formability, achieve the effect of reducing the incidence of cracks and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

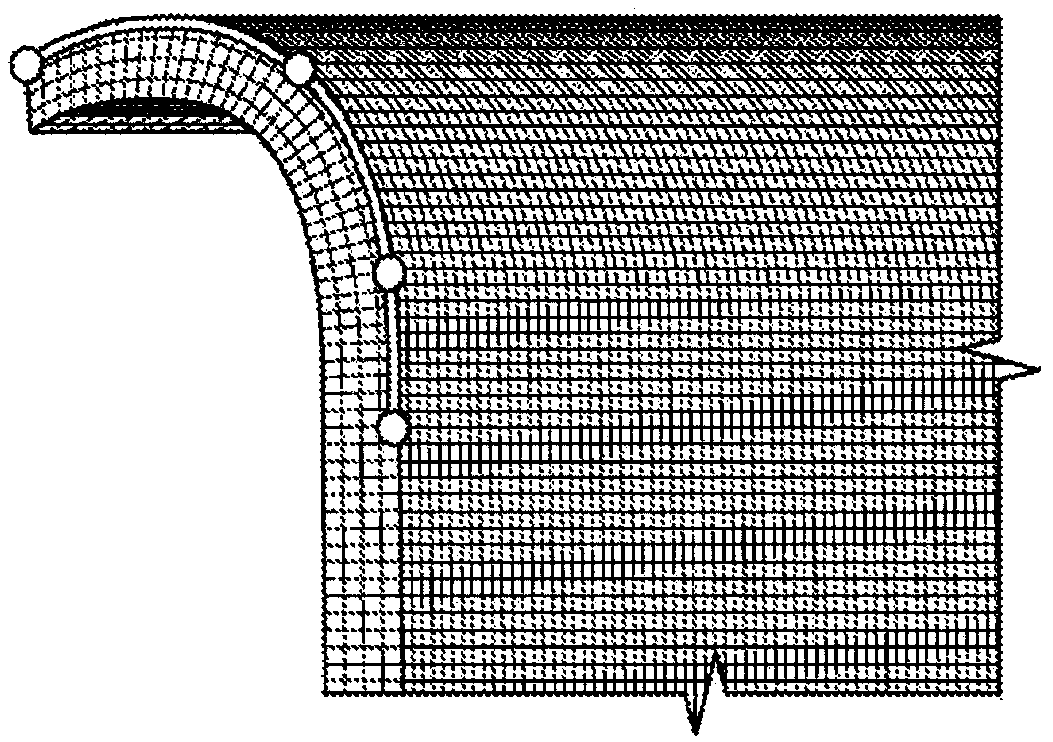

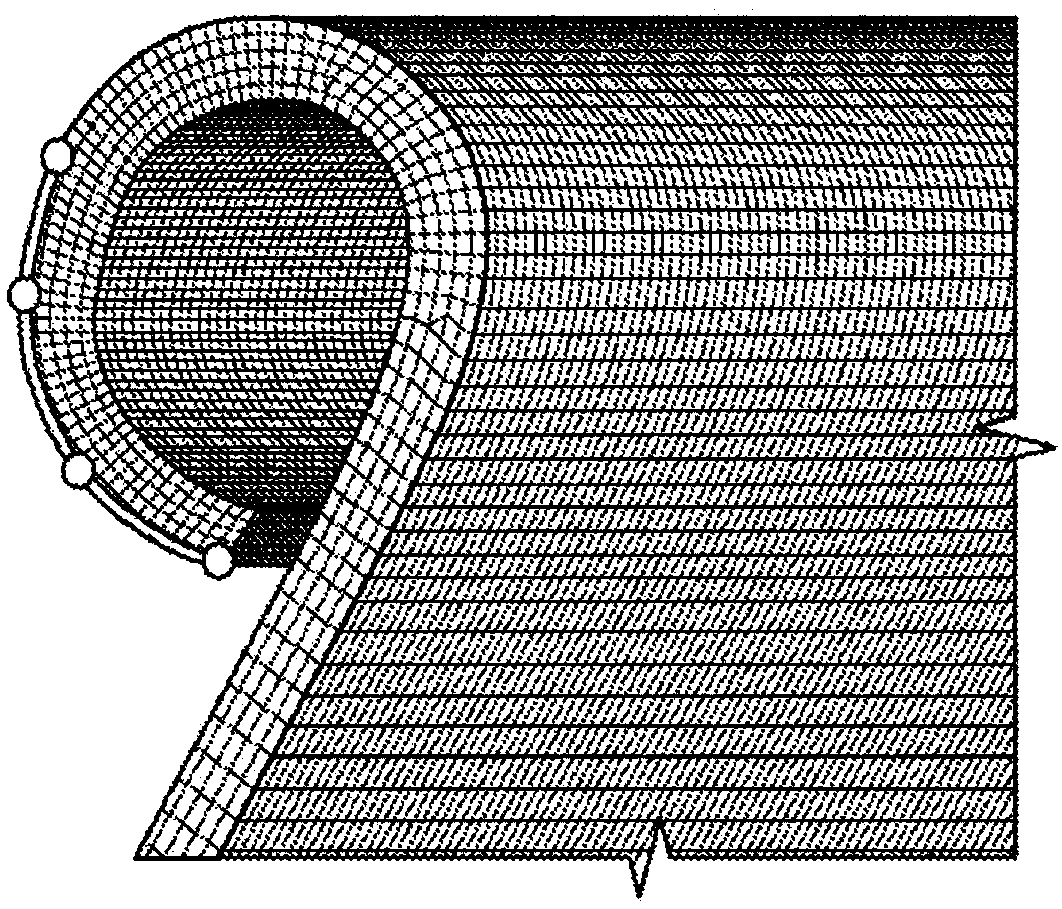

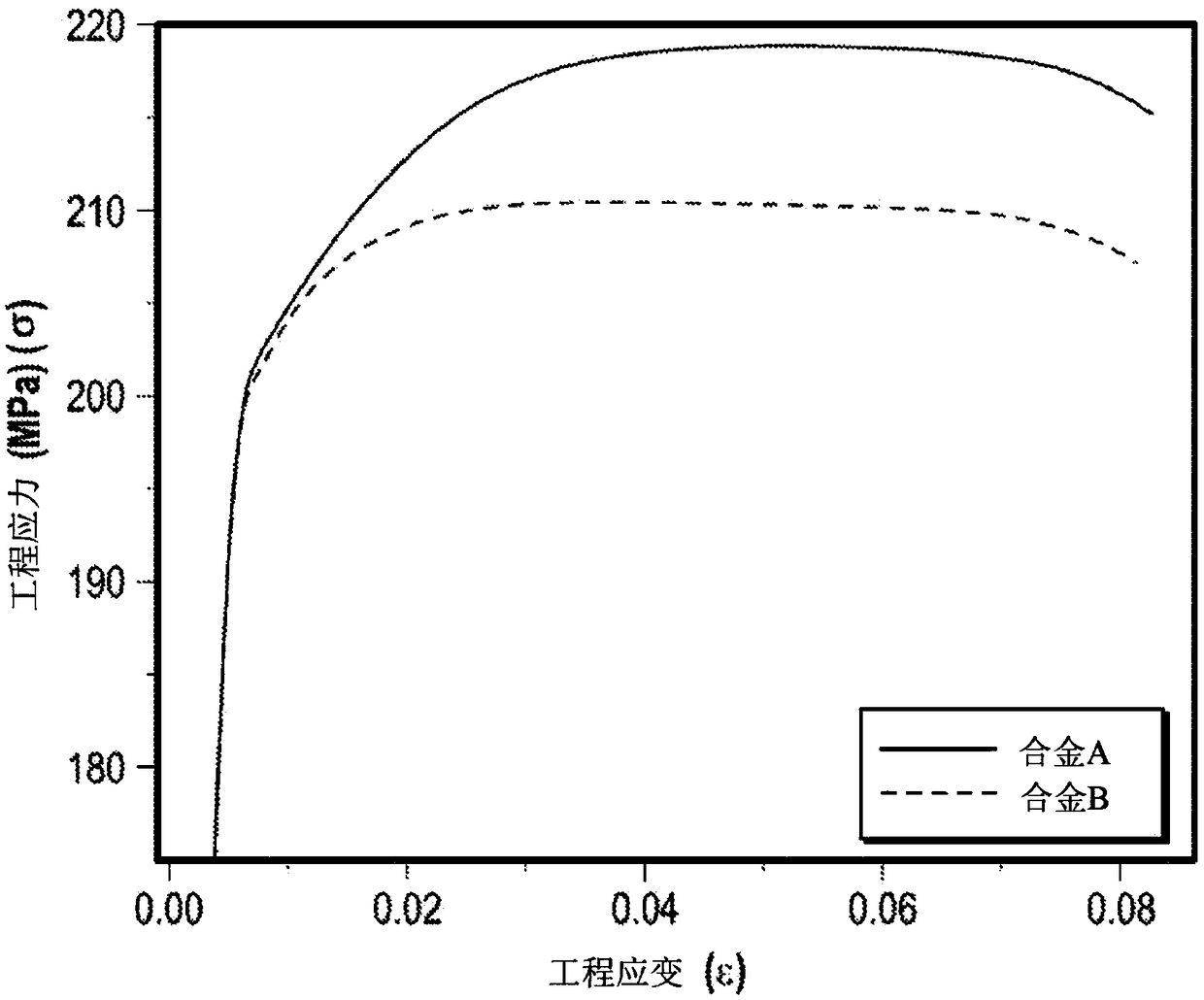

Image

Examples

Embodiment Construction

[0017] The subject matter of examples of the present invention is described herein in specific manner to satisfy statutory requirements, but this description is not necessarily intended to limit the scope of the claims. The claimed subject matter can be embodied in other ways, can contain different elements or steps, and can be used in combination with other present or future technologies. Unless an order of individual steps or an arrangement of elements is explicitly described, this specification should not be construed as implying any particular order or arrangement among or between individual steps or elements.

[0018] In this specification, reference is made to alloys identified by aluminum industry designations such as "series". For the numerical designation system most commonly used to name and identify aluminum and its alloys, see International Alloy Designations and Chemical Composition Limits for Wrought Aluminum and Wrought Aluminum Alloys, both published by the Alu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ultimate tensile strength | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com