Intelligent automatic organic fertilizer spreading machine

A technology of spreader, organic manure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

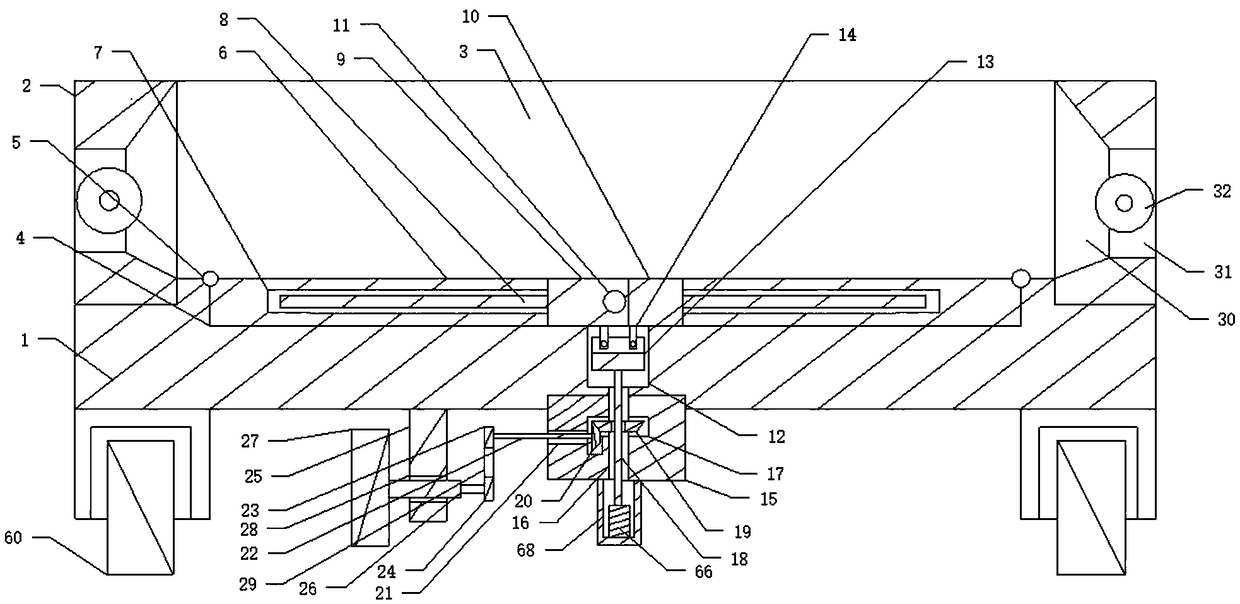

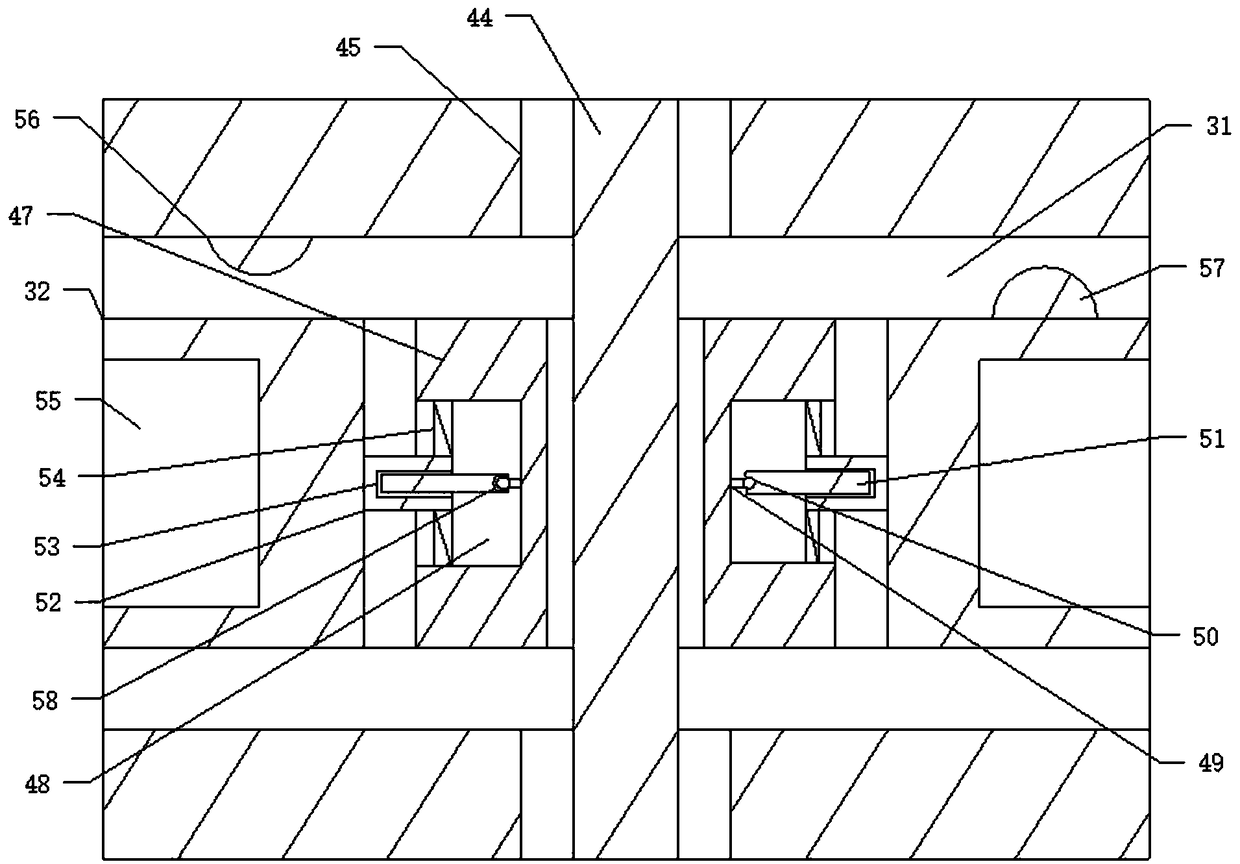

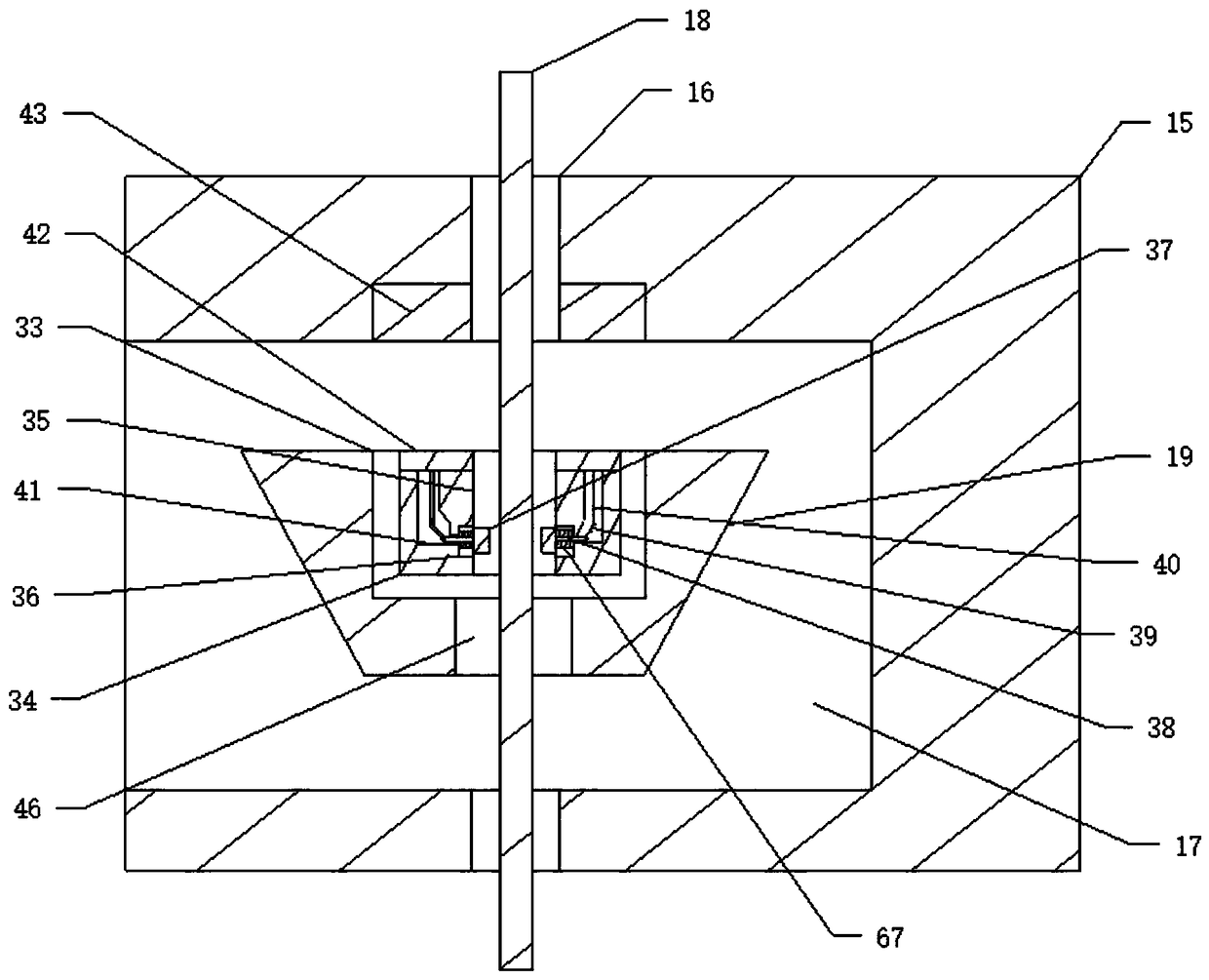

[0031] like Figure 1 to Figure 9 As shown, an automatic agricultural organic manure spreader includes a carriage floor 1, a second roller 60 is respectively arranged on both sides of the carriage floor 1, and a carriage side plate 2 is respectively connected to both sides of the carriage floor 1. The compartment side plate 2 and the compartment bottom plate 1 form a compartment trough 3, and a row of discharge openings 31 corresponding to the compartment trough 3 are respectively arranged on the compartment side plates 2 on both sides. A main shaft 44 that rotates in the discharge port 31 is respectively arranged in the side panel 2 of the carriage, and a discharge runner 32 that rotates in the discharge port 31 is respectively arranged on the main shaft 44 . The material runner 32 swings in the mouth of the discharge 31, and a compartment side plate 2 is respectively connected to both sides of the compartment floor 1, and an inner groove is formed between the compartment flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com