Ethylene oligomerization catalyst system and its preparation method and application

An ethylene oligomerization and catalyst technology, which is applied in the field of homogeneous zirconium catalyst system and its preparation, can solve the problems of clogging pipelines and affecting industrial production, and achieve the effects of avoiding the formation of high polymers, rational distribution and high yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

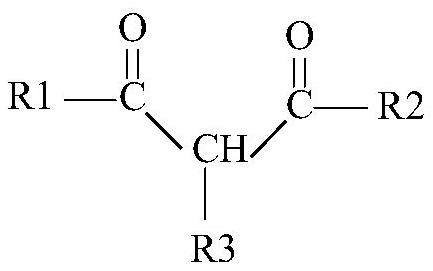

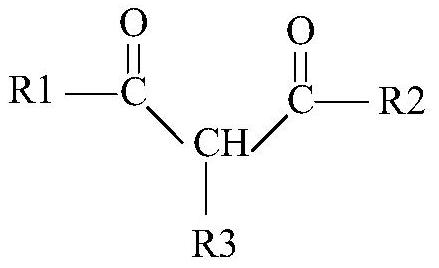

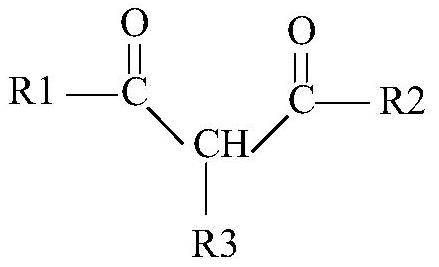

Image

Examples

preparation example Construction

[0069] The present invention provides a preferred method for preparing the one main catalyst, comprising:

[0070] (1) in an inert solvent, the ZrX 4 The reaction with an alcohol, the solution obtained in step; and

[0071] (2) The step (1) was obtained with the formula SiCl n Rim 4-n Silicon compound, thereby to obtain said procatalyst step of;

[0072] Wherein, X is Cl, Br, or I, n is 2, 3 or 4, R is a hydrocarbon group.

[0073] In the present invention, the inert solvent means a solvent adversely influence the reaction on the catalytic performance of ethylene oligomerization catalyst and oligomerization of ethylene.

[0074] In the present invention, the inert solvent is preferably benzene, toluene, xylene, mesitylene, n-hexane or cyclohexane, and any mixtures thereof between.

[0075] The main method of preparing the catalyst, the reaction temperature in step (1) is from 60 ℃ ~ 120 ℃, preferably 60 ℃ ~ 80 ℃.

[0076] The main method of preparing the catalyst, the reaction tem...

Embodiment 1

[0099] This example illustrates the preparation of a catalyst system of the present invention, the oligomerization of ethylene.

[0100] The 2.33g (10mmol) ZrCl 4 Placed in three-necked flask, toluene was added 30mL, was heated to 70 ℃, stirred for 1 hour, 30mmol of n-butanol, 85 deg.] C to reflux for 4 hours, cooled to 0 deg.] C, was added 3.82 mL (30mmol) of trimethylchlorosilane reaction 4 hours, 5mmol dibenzoylmethane, and then toluene was added to a solution of 50mL, oligomerization catalyst solution to give a zirconium concentration of 0.2 mol / liter A.

Embodiment 2

[0102] This example illustrates the preparation of a catalyst system of the present invention, the oligomerization of ethylene.

[0103] Using the same method of Example 1, except that only: an amount of 2 mmol of dibenzoylmethane, to prepare a catalyst solution B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com