Water conservancy project pipeline dredging method

A technology for water conservancy projects and pipelines, which is applied to cleaning methods and appliances, chemical instruments and methods, and cleaning hollow objects, etc. It can solve the problems of pipeline silt accumulation and blockage, and achieve the effects of small equipment size, labor saving, and simple dredging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

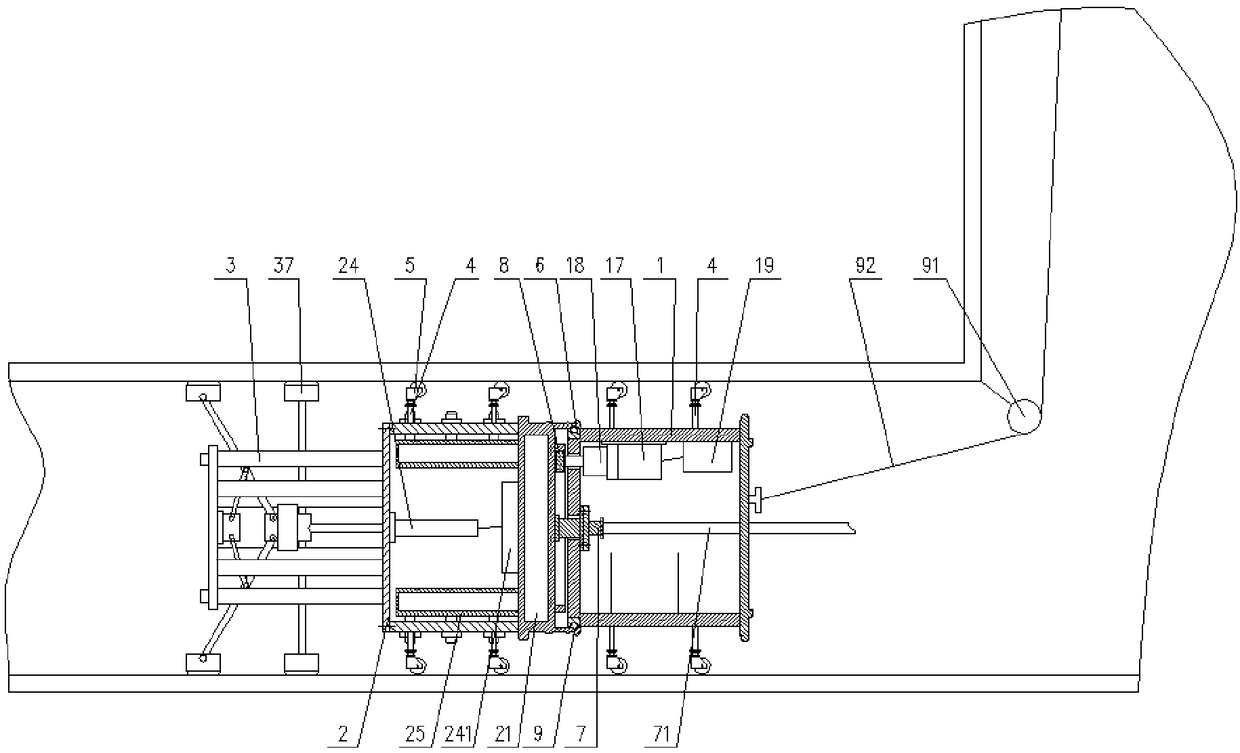

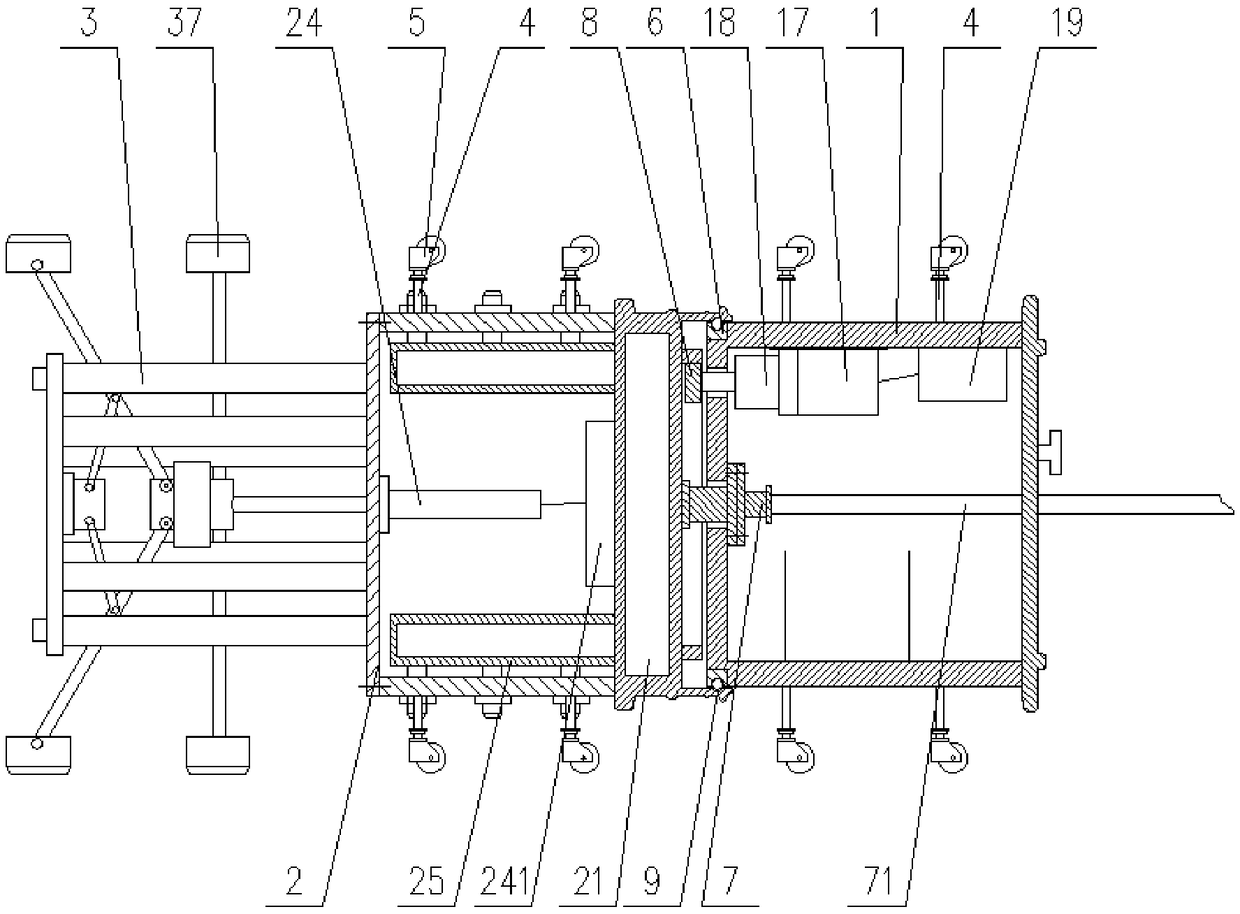

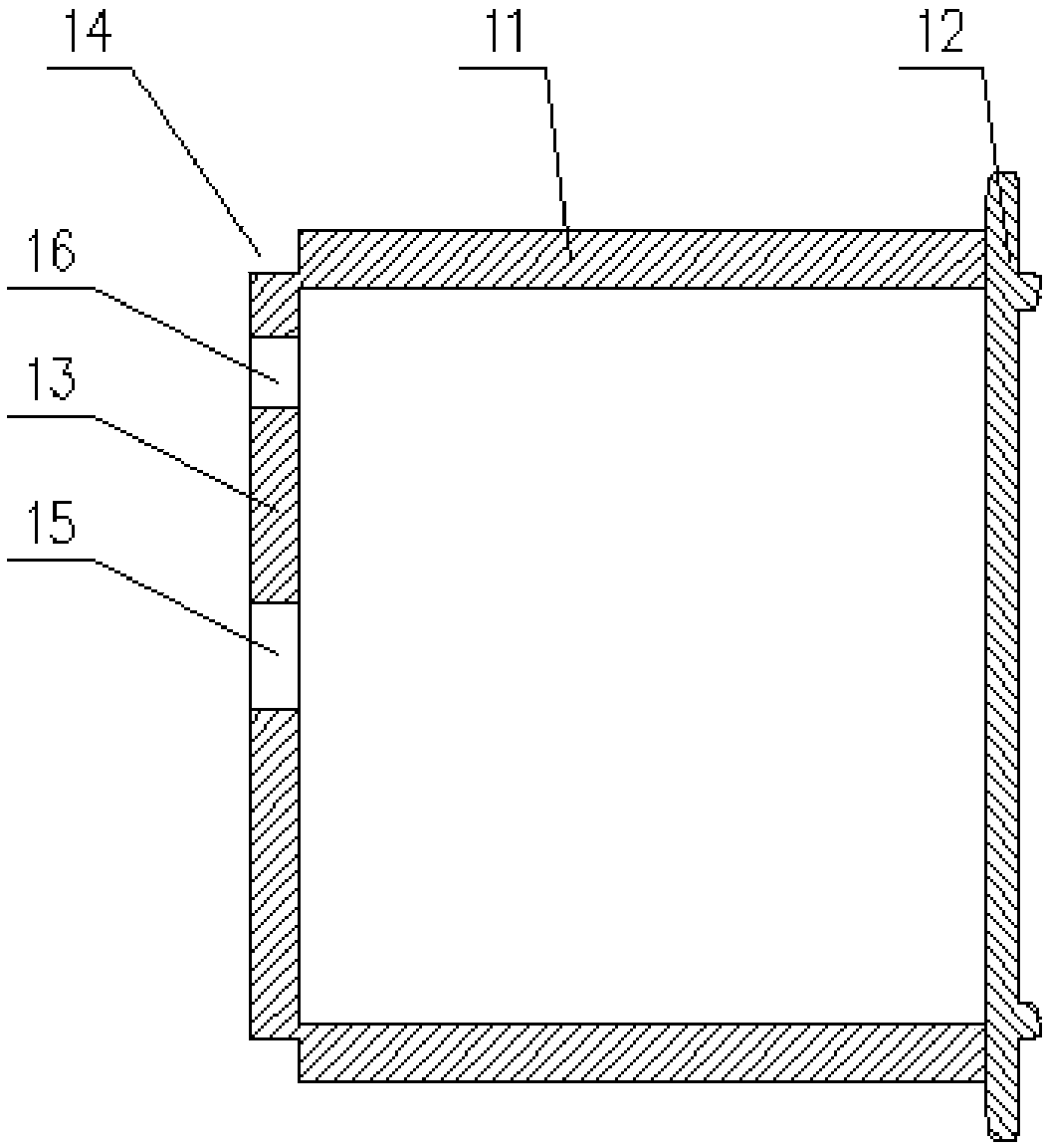

[0036] Specific implementation mode one: combine figure 1 and Figure 7Describe this embodiment, a water conservancy project pipeline dredging device in this embodiment, including a driving base 1, a pipeline sludge flushing device 2 and a pipeline washing device 3, the overall shape of the driving base 1 is cylindrical, and the outer wall of the driving base A support rod 4 is installed on the support rod 4, and a traveling wheel 5 is installed on the supporting rod 4. The traveling wheel 5 is a universal traveling wheel, and the driving base 1 includes a base housing 11 and a bottom cover 12. The base housing 11 The right end is an open structure, and a bottom cover 12 is installed on the right end of the base shell 11. An annular groove 14 is processed on the left side wall 13 of the base of the base shell 11, and an annular slide rail is installed in the annular groove 14. 6. The center position of the left side wall 13 of the base shell 11 is processed with a rotary adap...

specific Embodiment approach 2

[0038] Specific implementation mode two: combination figure 1 and Figure 7 Describe this embodiment, a water conservancy project pipeline desilting device in this embodiment, the pipeline sludge flushing device 2 includes a water storage box 21, a flushing installation box 22, a flushing installation box cover 23, an electric push rod 24, The flushing pipe 25 and the flushing head 26, the right side of the water storage box 21 are respectively provided with a slider 9 and an inner ring gear 10, and the water storage box 21 is connected to the rotating shaft installed in the center of the left side wall 13 of the base. The joint 7 is connected, and the left side of the water storage box 21 is connected with a plurality of flushing pipes 25. The flushing installation box 22 is welded and installed on the left side of the water storage box 21. The flushing pipes 25 are arranged in the flushing installation box. 22, a flushing head 26 is installed on the flushing pipe 25, and th...

specific Embodiment approach 3

[0040] Specific implementation mode three: combination figure 1 and Figure 7 Describe this embodiment, a water conservancy project pipeline desilting device of this embodiment, the right side of the water storage box 21 has a water inlet 211, and the rotation of the water inlet 211 and the center position of the left side wall 13 of the base The adapter 7 is connected, and the left side of the water storage box 21 has water outlets 212 in an annular array, and each water outlet 212 is sealed with a flushing pipe 25 . In this way, the water inlet 211 is used to communicate with the rotary adapter 7 , and the water outlet 212 is communicated with the flushing pipe 25 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com