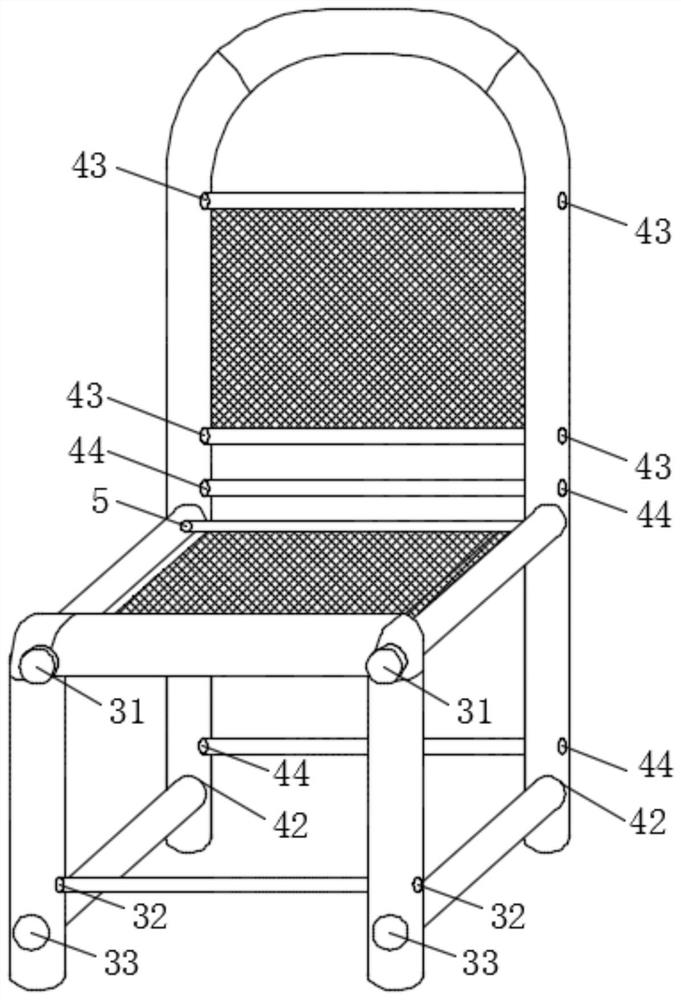

A combined bamboo chair and its manufacturing method

A manufacturing method and combined technology, applied in the field of furniture manufacturing, can solve problems such as insufficient comfort and difficult transportation of bamboo chairs, and achieve the effects of reducing discomfort, facilitating long-term storage, and reducing insects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

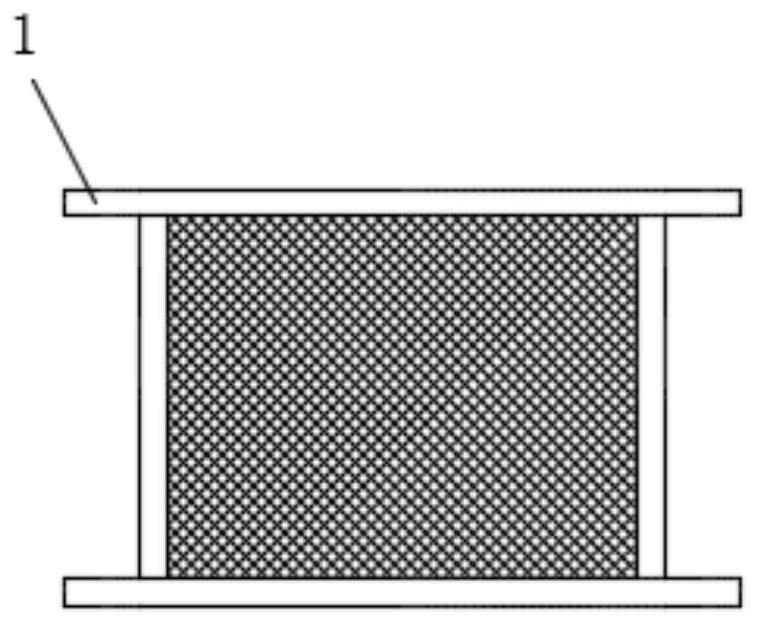

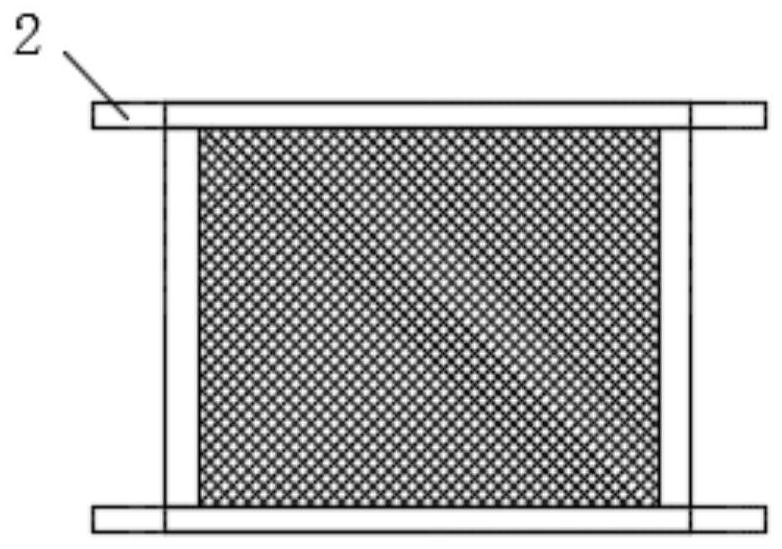

[0030] The manufacturing method of the combined bamboo chair provided by this embodiment includes the following steps: making the stool surface, making the front stool legs, making the rear stool legs, making the back pad, assembling and coloring, and making the stool surface includes making the seat cushion and making the fixed rod ;

[0031] Cushion production: Select Cizhu with a bamboo age of 2 years, move the elongation knot 0.5cm to saw the bamboo tube, scrape the bamboo tube, and then divide the scraped bamboo tube into pieces along the end surface, and the width of the separated bamboo pieces is 1.5cm, starting from the side close to the green bamboo, divide the bamboo block into 4 layers of bamboo strips along the thickness direction of the bamboo block, each layer of bamboo strips is 0.5mm thick, and weave the bamboo strips into a single-layer mat according to the principle of plane weaving. Four layers of single-layer mats are overlapped to form a combined mat, plac...

Embodiment 2

[0041] The manufacturing method of the combined bamboo chair provided by this embodiment includes the following steps: making the stool surface, making the front stool legs, making the rear stool legs, making the back pad, assembling and coloring, and making the stool surface includes making the seat cushion and making the fixed rod ;

[0042] Cushion production: Select Cizhu with a bamboo age of 2 years, move the elongation knot 0.5cm to saw the bamboo tube, scrape the bamboo tube, and then divide the scraped bamboo tube into pieces along the end surface, and the width of the separated bamboo pieces is 1.6cm, starting from the side close to the green bamboo, divide the bamboo block into 4 layers of bamboo strips along the thickness direction of the bamboo block, each layer of bamboo strips is 0.6mm thick, and weave the bamboo strips into a single-layer mat according to the principle of plane weaving. Four layers of single-layer mats are overlapped to form a combined mat, whic...

Embodiment 3

[0052] The manufacturing method of the combined bamboo chair provided by this embodiment includes the following steps: making the stool surface, making the front stool legs, making the rear stool legs, making the back pad, assembling and coloring, and making the stool surface includes making the seat cushion and making the fixed rod ;

[0053] Cushion production: Select Cizhu with a bamboo age of 3 years, move the elongated knot 0.5cm to saw the bamboo tube, scrape the bamboo tube, and then divide the scraped bamboo tube into pieces along the end surface, and the width of the separated bamboo pieces is 1.8cm, starting from the side close to the bamboo green, divide the bamboo block into 4 layers of bamboo strips along the thickness direction of the bamboo block, each layer of bamboo strips is 0.8mm thick, and weave the bamboo strips into a single-layer mat according to the principle of plane weaving. Four layers of single-layer mats are overlapped to form a combined mat, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com