A control system and a control method of a trackless cable conveyor

A technology of control system and transport aircraft, applied in the direction of transportation and packaging, motor vehicles, cable railways, etc., can solve the problems of unsuitable use requirements and high overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

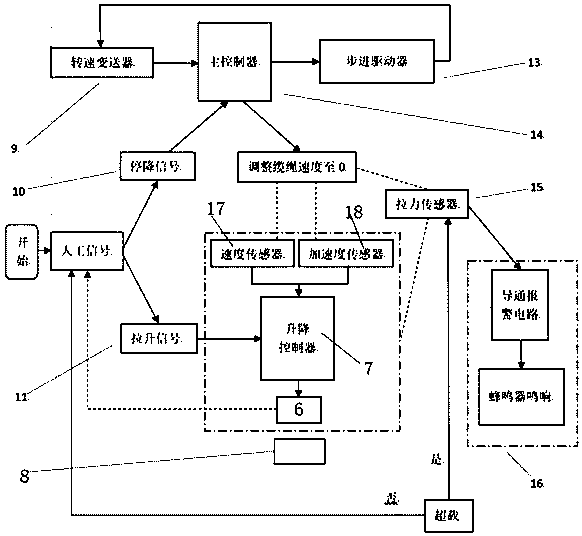

Method used

Image

Examples

Embodiment 1

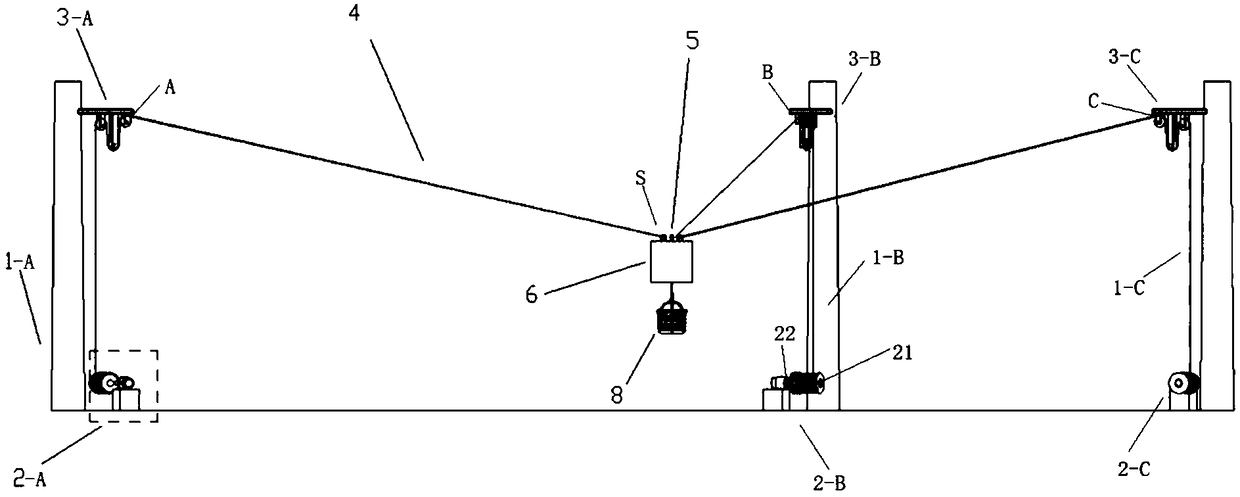

[0060] Such as figure 1 , 3 As shown in 4, the trackless cable conveyor of this embodiment includes active sling towers 1-A, driven sling towers 1-B and 1-C, which are set on three mountain tops, and drive stepping motors 2-A, 2 -B and 2-C, the cable retractable assembly includes a reducer 22, a drum 21; three-wheeled pulley block 3-A, 3-B, 3-C, three steel cables 4, connected to the turntable 5, and DC gear motor 6, One end of the steel cable 4 is fixed to the drums installed on the active sling tower and the two driven sling towers, and the other end is fixed to the connecting turntable (ie, control point S). Three sets of driving stepper motors The speed control of the three cables affects the low-altitude suspension transportation of the suspension box 8. A tension sensor 15 is arranged between the suspension box 8 and the DC reduction motor 6, and the signal of the tension sensor is input to the transistor alarm circuit 16 inside the suspension box 8 as a trigger signal. ...

Embodiment 2

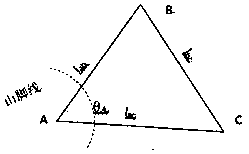

[0069] Such as Figure 2a with 2b , The horizontal distance between the two active sling tower point A and the driven sling tower point B at the top of the mountain is set to 320m; the height of the fruit mountain is between 200 and 350, and the height difference between adjacent fruit mountains is in the range of Δh Between 10m and 50m, we set the mountain height to 240m; the fruit mountain slope is between 30°~45°, and we set the inclination angle of the suspension box 8 downhill transportation route to 36.87° The transportation process is: a suspension box filled with picked fruits (total mass 100kg) is placed on the active sling tower point A on the top of the mountain, and hooks at the end of the ropes are hung, and two or three cables are connected to each hook. The other end of each cable is connected to a reel, and the reel is externally driven by a stepping motor and a reducer. Therefore, each cable is driven by a separate stepping motor to control the traction speed, ...

Embodiment 3

[0081] Contains one active sling tower point A and two driven sling tower points B and C. The working area is a triangular area surrounded by three points. We set the horizontal distance between the active sling tower point A and the driven sling tower point B, and the active sling tower point A and the driven sling tower point C to 320m; the height of the fruit mountain is between 200 and 350. The range of height difference Δh between adjacent fruit mountains is between 10m and 50m. We set the height of the mountain to 240m; the slope of Guoshan is between 30°~45°, and we set the inclination of the downhill transportation route to 36.87°

[0082] Even so, the suspension box transportation route model of Guoshan where each sling tower is located is the same as the two-dimensional model, which is approximated by a straight line to build the model. Of course, the triangular area may only contain the fruit mountain where the three sling tower points are located, or it may contain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com