Distilled water generator

A distilled water and generator technology, applied in the field of equipment for generating distilled water, can solve the problems of less distilled water and power consumption, and achieve the effects of less scale, less energy consumption, and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

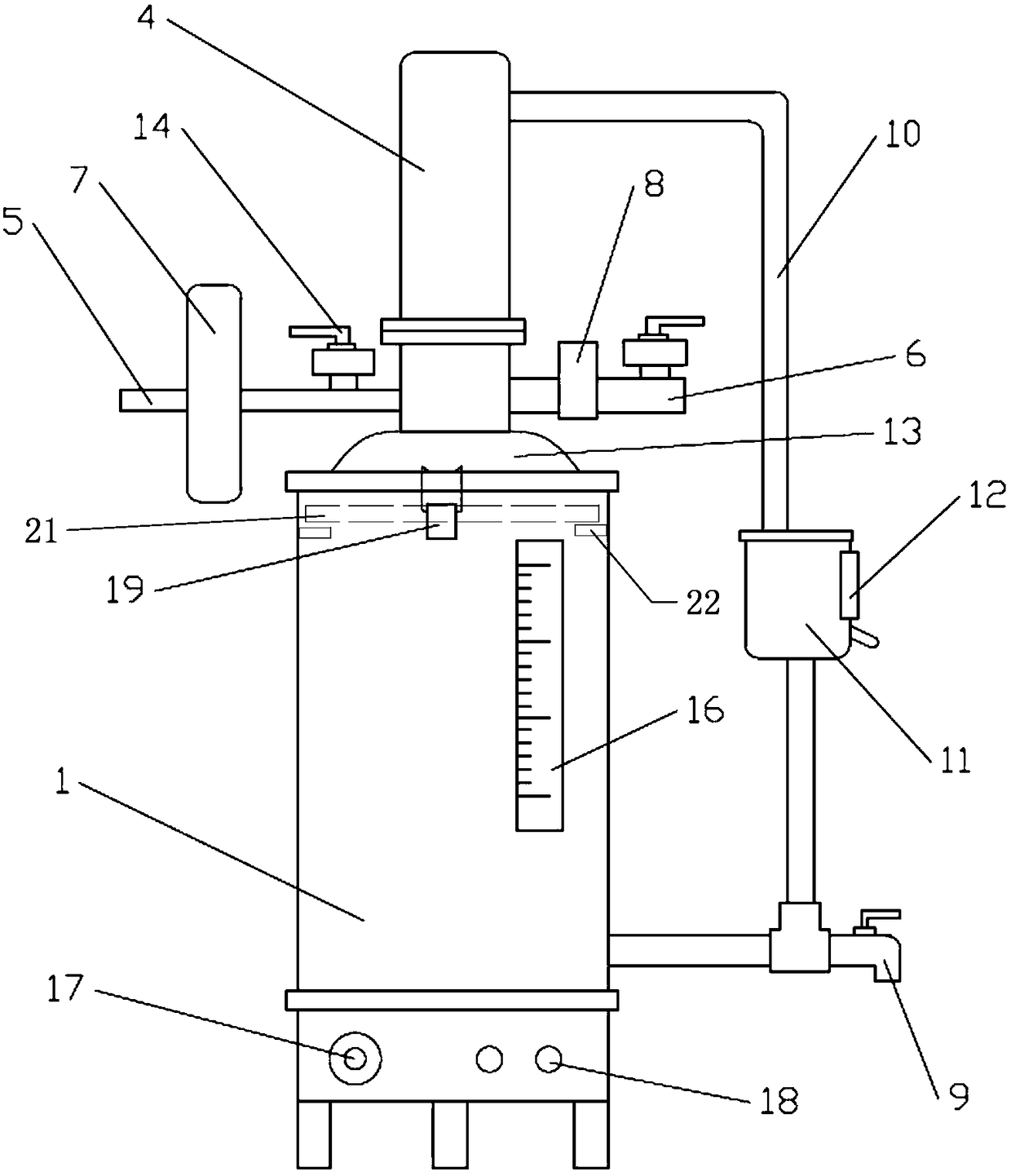

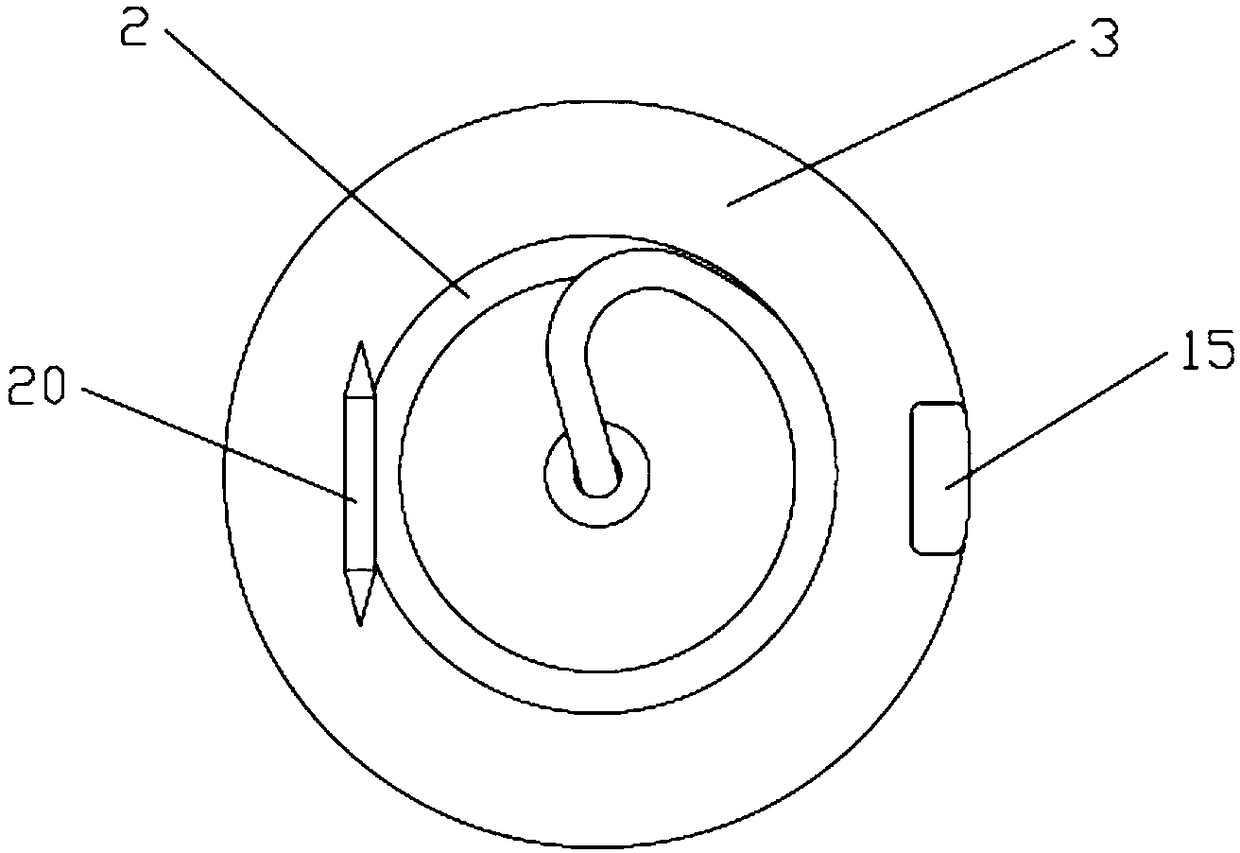

[0022] Such as figure 1 and figure 2 As shown, one of the embodiments provided by the present invention is a distilled water generator, including a tank body 1, a first heating tube 2 is arranged at the bottom of the tank body 1, and an evaporation chamber 3 is arranged above the first heating tube 2 , the top of the tank body 1 is provided with a condenser 4 .

[0023] In order to solve the problem of increased energy consumption and reduced output of distilled water after depositing scale on the first heating tube 2, a second heating tube 21 and a bracket 22 supporting the second heating tube 21 are arranged on the top of the tank body 1, and the second heating tube 21 and bracket 22 are arranged in the tank body 1 .

[0024] In this embodiment, on the basis of setting the first heating tube 2 at the bottom of the tank body 1, a second heating tube 21 and a bracket 22 supporting the second heating tube 21 are set on the top of the tank body 2, thereby forming two-stage he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com