Liquid organic fertilizer production fermentation device

A fermentation device and organic fertilizer technology, applied in organic fertilizers, fertilization devices, organic fertilizer equipment, etc., can solve problems such as low product quality, high labor intensity, and complicated production process, and achieve high resource utilization, environmental protection, The effect of fast production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

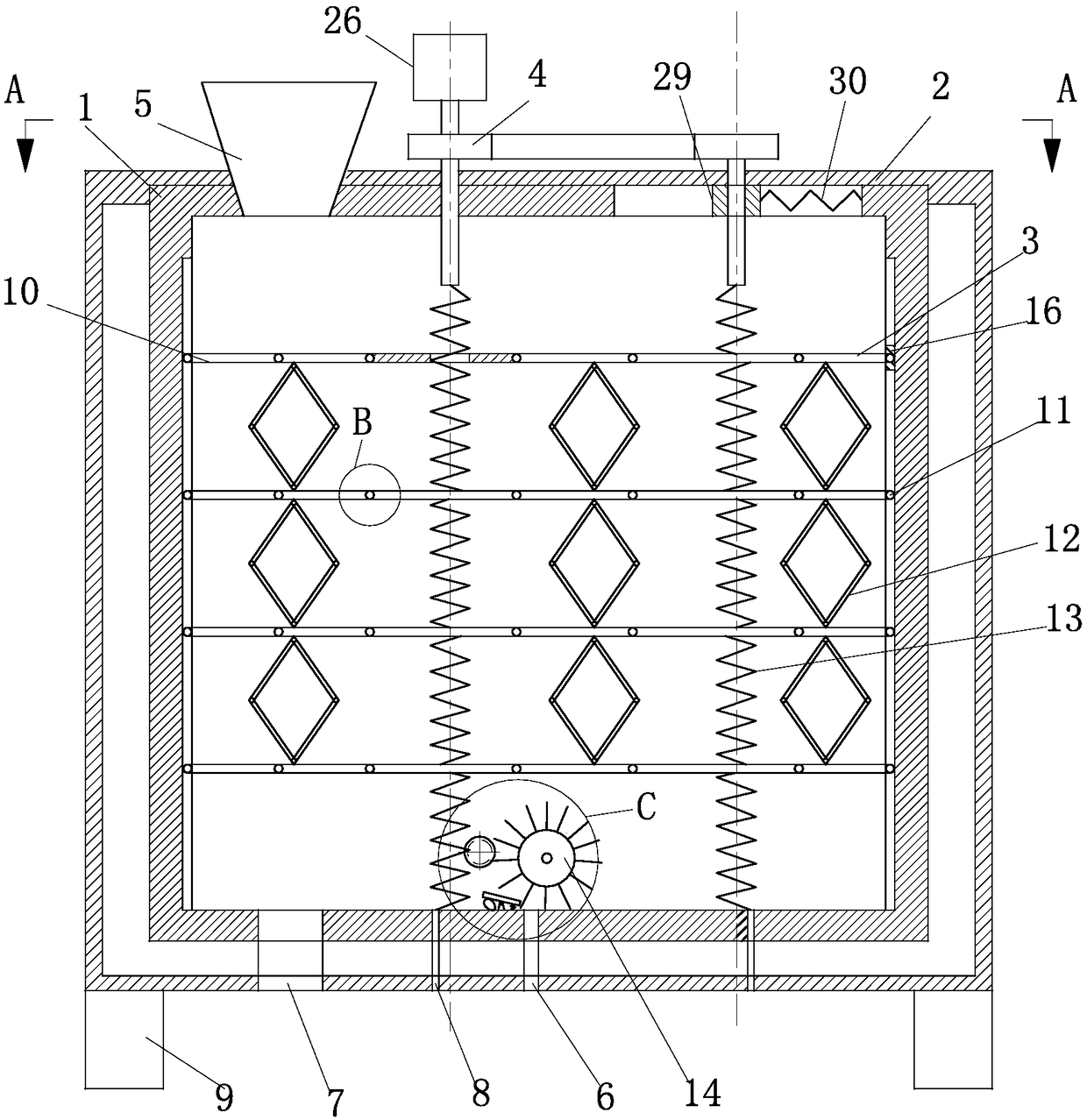

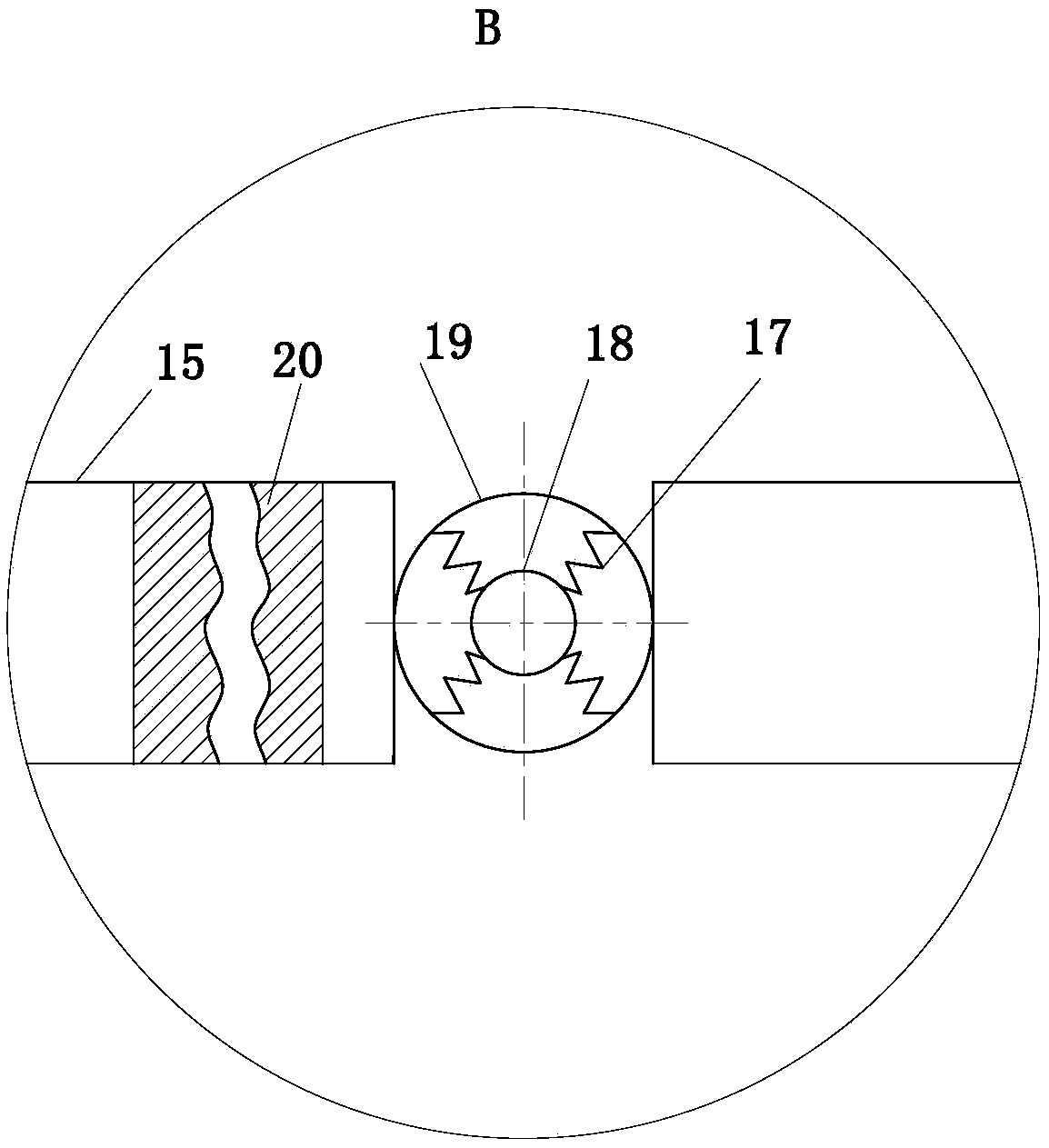

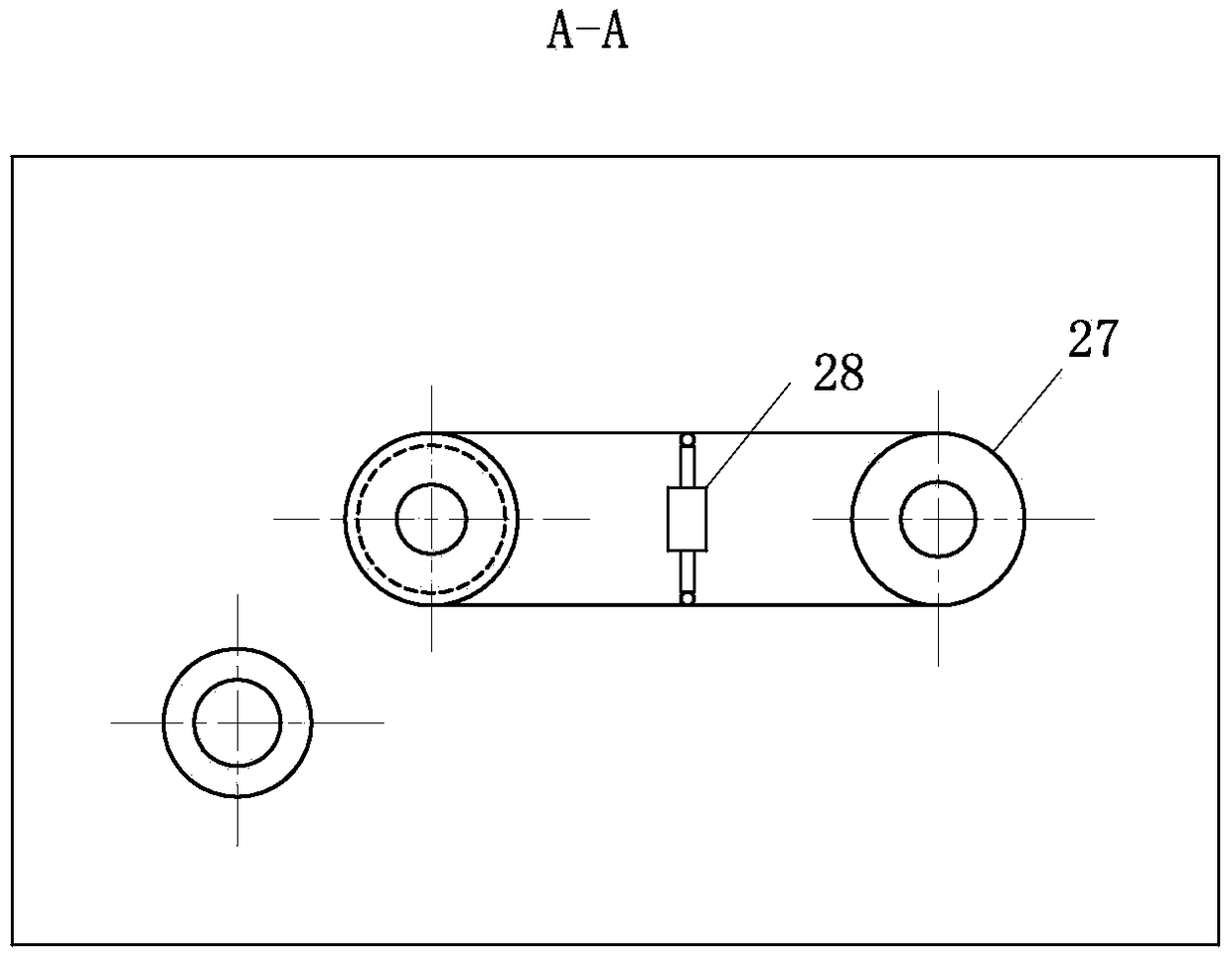

[0021] Such as Figure 1 to Figure 4 As shown, a fermentation device for producing liquid organic fertilizer includes a fermentation tank 1, a heat preservation device 2, a stirring device 3 and a power unit 4; suitable temperature; the power unit 4 is placed above the fermentation tank 1 to provide stirring power for the fermentation tank 1; the stirring device 3 is located inside the fermentation tank 1 to ensure that the fermented product can be fully and evenly mixed to improve production efficiency; The upper left side of the fermentation tank 1 is provided with a feeding port 5; the middle position below the fermentation tank 1 is provided with a discharge port 6; the lower left side of the fermentation tank 1 is provided with a sewage outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com