A method for rapidly aging apple brandy by wood vinegar combined with ultrasonic treatment

A technology for apple brandy and wood vinegar, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, preparation of alcoholic beverages, etc. Soft, flavor-rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

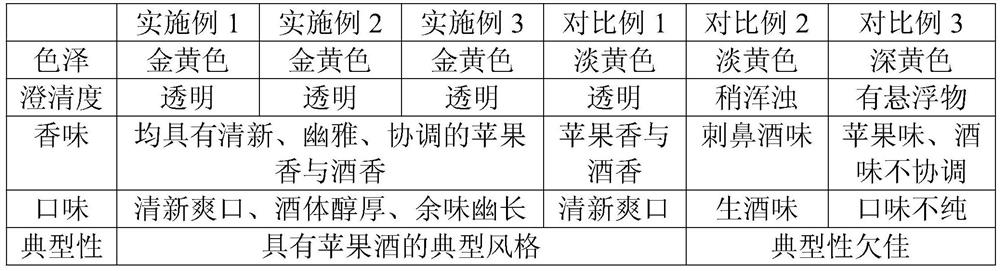

Examples

Embodiment 1

[0018] (1) Prepare apple brandy by conventional technology: clean the fresh apples that are fully matured in October-December, break them into uniform apple pieces with a beater, and squeeze out the apple juice in time. The volume of the apple pieces is 0.9-1.1 cubic centimeters After adjusting the sugar content of apple juice to 20%, add 200ppm activated active dry yeast and ferment for 20 days at 23°C to obtain an apple fermented wine with an alcohol content of 10%, and then distill the apple fermented wine twice to obtain Apple brandy with 50% alcohol, distilled in stills;

[0019] (2) Take out 500mL apple brandy stock solution, add 1‰ wood vinegar and shake well. The wood vinegar is passed through the condenser to cool the smoke generated when corn stalks are carbonized at 300±2℃, and then condensed The liquid mixture was left to stand for 6 months, and the middle layer refined wood vinegar obtained after discarding the unstable wood vinegar of the upper floor and the harm...

Embodiment 2

[0022] (1) Prepare apple brandy by conventional technology: clean the fresh apples that are fully matured in October-December, break them into uniform apple pieces with a beater, and squeeze out the apple juice in time. The volume of the apple pieces is 0.9-1.1 cubic centimeters After adjusting the sugar content of apple juice to 20%, add 200ppm activated active dry yeast and ferment for 40 days at 23°C to obtain an apple fermented wine with an alcohol content of 10%, and then distill the apple fermented wine twice to obtain Apple brandy with 50% alcohol, distilled in stills;

[0023] (2) Take out 500mL of apple brandy stock solution, add 2‰ of wood vinegar and shake well. The wood vinegar is passed through the condenser to cool the smoke generated when corn stalks are carbonized at 300±2℃, and then condensed The liquid mixture was left to stand for 6 months, and the middle layer refined wood vinegar obtained after discarding the unstable wood vinegar of the upper floor and th...

Embodiment 3

[0026] (1) Prepare apple brandy by conventional technology: clean the fresh apples that are fully matured in October-December, break them into uniform apple pieces with a beater, and squeeze out the apple juice in time. The volume of the apple pieces is 0.9-1.1 cubic centimeters After adjusting the sugar content of the apple juice to 20%, add 200ppm of activated active dry yeast, ferment for 30 days at 23°C to obtain an apple fermented wine with an alcohol content of 10%, and then distill the apple fermented wine twice to obtain Apple brandy with 50% alcohol, distilled in stills;

[0027] (2) Take out 500mL of apple brandy stock solution, add 3‰ of wood vinegar and shake well. The wood vinegar is passed through the condenser to cool the smoke generated when corn stalks are carbonized at 300±2℃, and then condensed The liquid mixture was left to stand for 6 months, and the middle layer refined wood vinegar obtained after discarding the unstable wood vinegar of the upper floor an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com