Underground pipe gallery pipe section assembly equipment and construction method

A technology for underground pipe galleries and pipe joints, which is applied to artificial islands, water conservancy projects, underwater structures, etc., and can solve the requirements of increasing the probability of water seepage and leakage at joints, many joints between joints of pipe gallery, and the accuracy of joint assembly Advanced problems, to achieve the effect of reducing labor intensity, safe construction, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

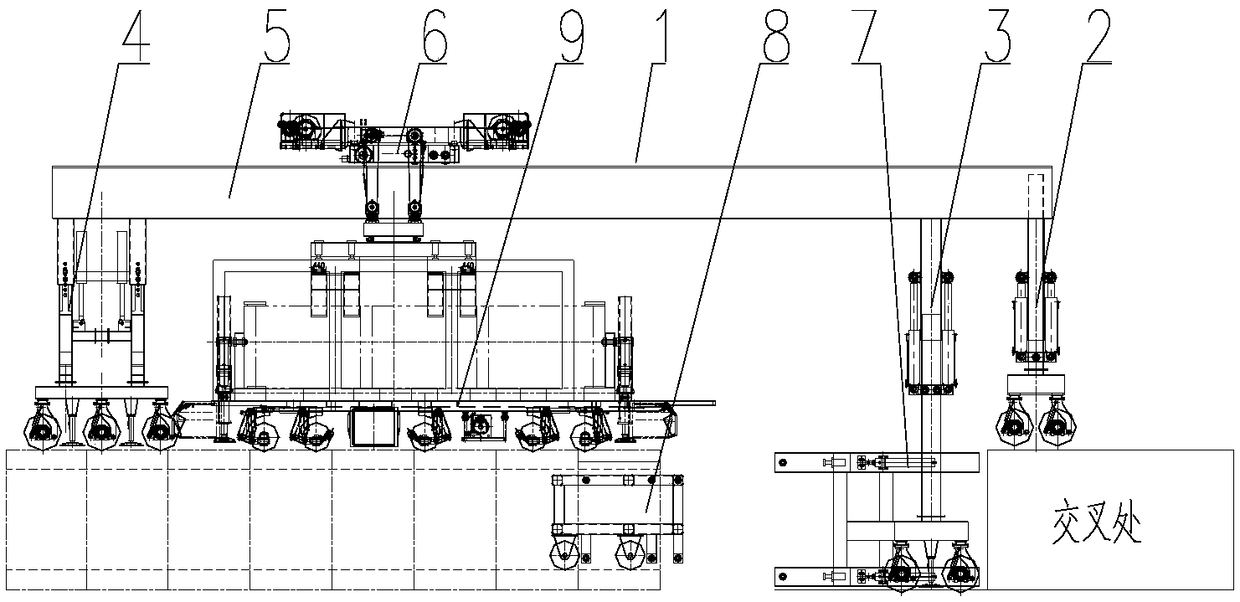

[0056] see Figure 1 to Figure 5 , showing the underground pipe gallery pipe section assembling equipment of the present invention.

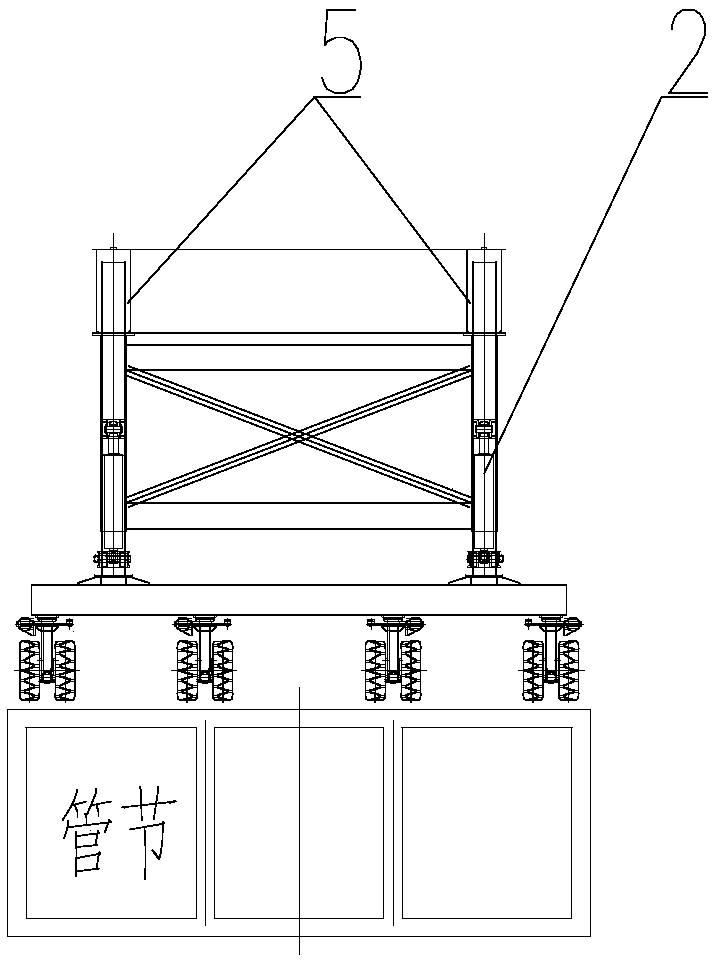

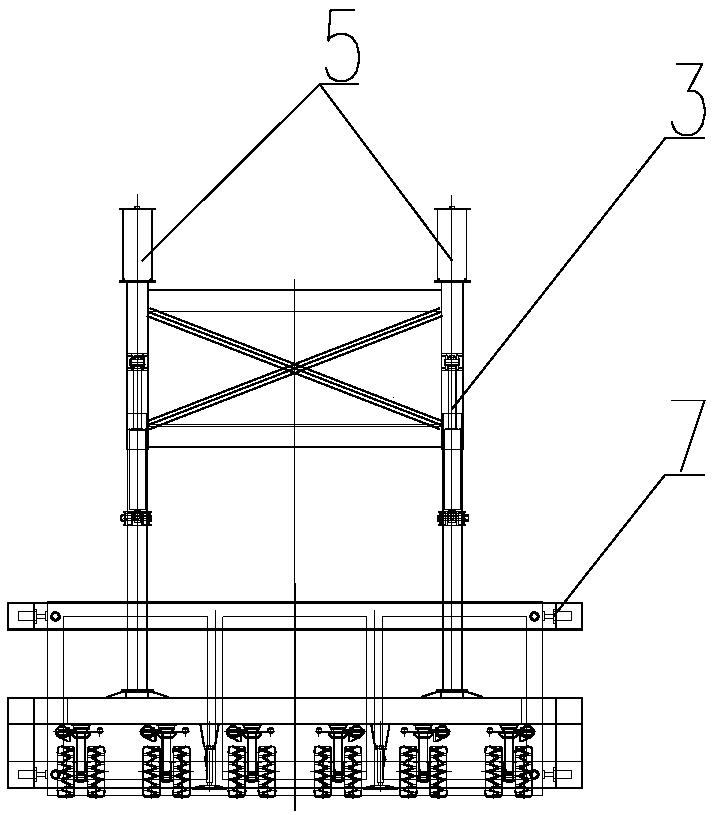

[0057] The underground pipe gallery pipe section assembling equipment includes a pipe racking machine 1, an assembling robotic arm 7, an alignment trolley 8 and a pipe transporting vehicle 9. The pipe racking machine 1 includes a main beam 5, auxiliary legs 2, and front legs 3. , the rear outrigger 4 and the crane 6, the front end of the main beam is provided with an auxiliary outrigger 2, the rear end is provided with a rear outrigger 4, and the main beam 5 is provided with a front outrigger behind the auxiliary outrigger 2 Leg 3, the auxiliary leg 2 is provided with a telescopic cylinder and a running wheel set, and the front supporting leg 3 and the rear supporting leg 4 are provided with a telescopic cylinder, a running wheel set and a hydraulic supporting leg (see image 3), the upper surface of the main beam 5 is provided with a track for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com