Prefabricated enclosure wall coping and manufacturing and construction methods thereof

A fence and flat roof technology, which is applied in the field of prefabricated fence roofing and its production and construction, can solve problems such as inconsistency of wall roofing specifications, and achieve the effects of saving man-hours, avoiding dust pollution, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

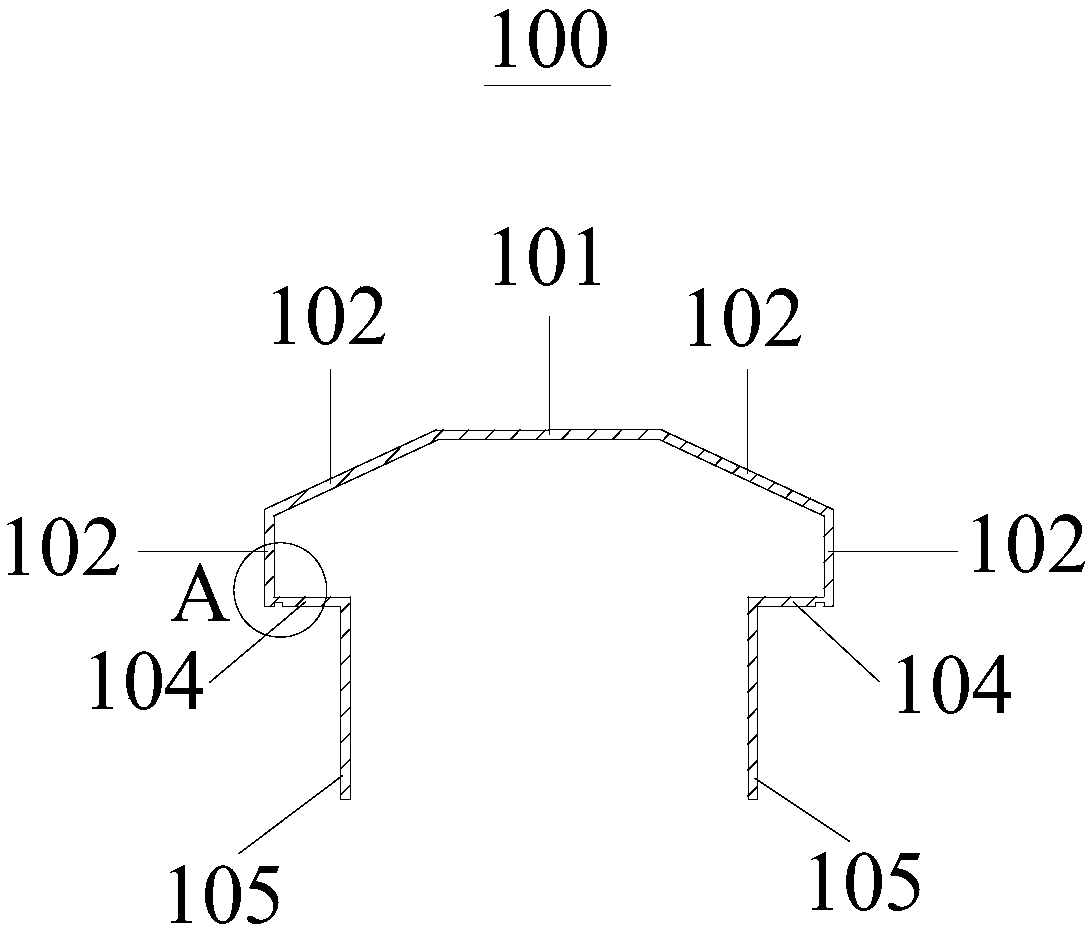

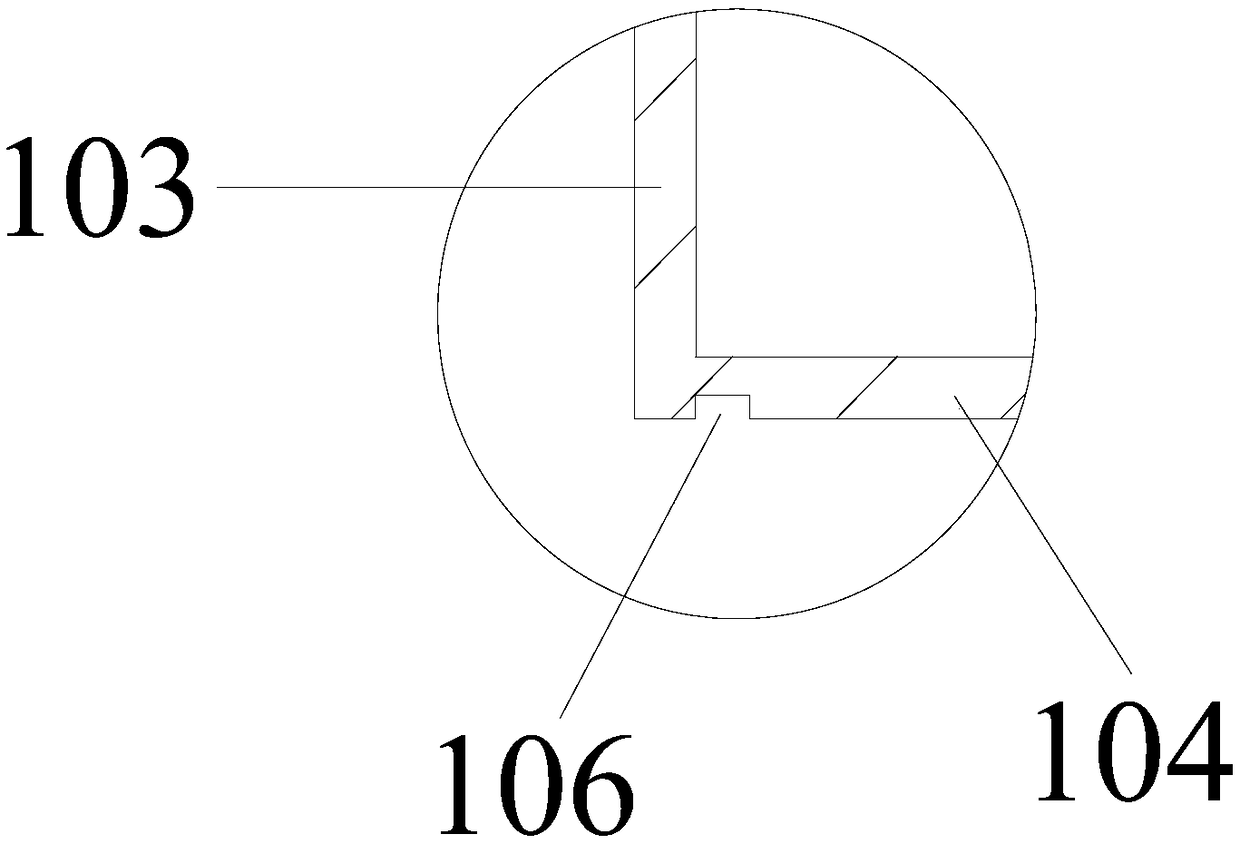

[0028] Please refer to Figure 1 to Figure 2 , The first embodiment provides a prefabricated enclosure wall pressure top 100, including a horizontally arranged flat top plate 101, an inclined top plate 102 connected along both ends of the flat top plate 101, the inclined top plate 102 is arranged at an angle relative to the flat top plate 101, and The side top plate 103 connected to the inclined top plate 102 is provided with a shielding plate 104 close to the vertical center of the flat top plate 101, and a fixing plate 105 is perpendicularly connected to the shielding plate 104.

[0029] The prefabricated wall pressing top 100 provided in the first embodiment has the effect of waterproof and rainproof. When the rain is heavy, the water is drained from the outside of the wall 200 through the flat top plate 101 and the inclined top plate 102. When the rain is small, the water drips on the flat surface. The water on the top plate 101 drips to the outside of the enclosure wall 200 t...

Embodiment 2

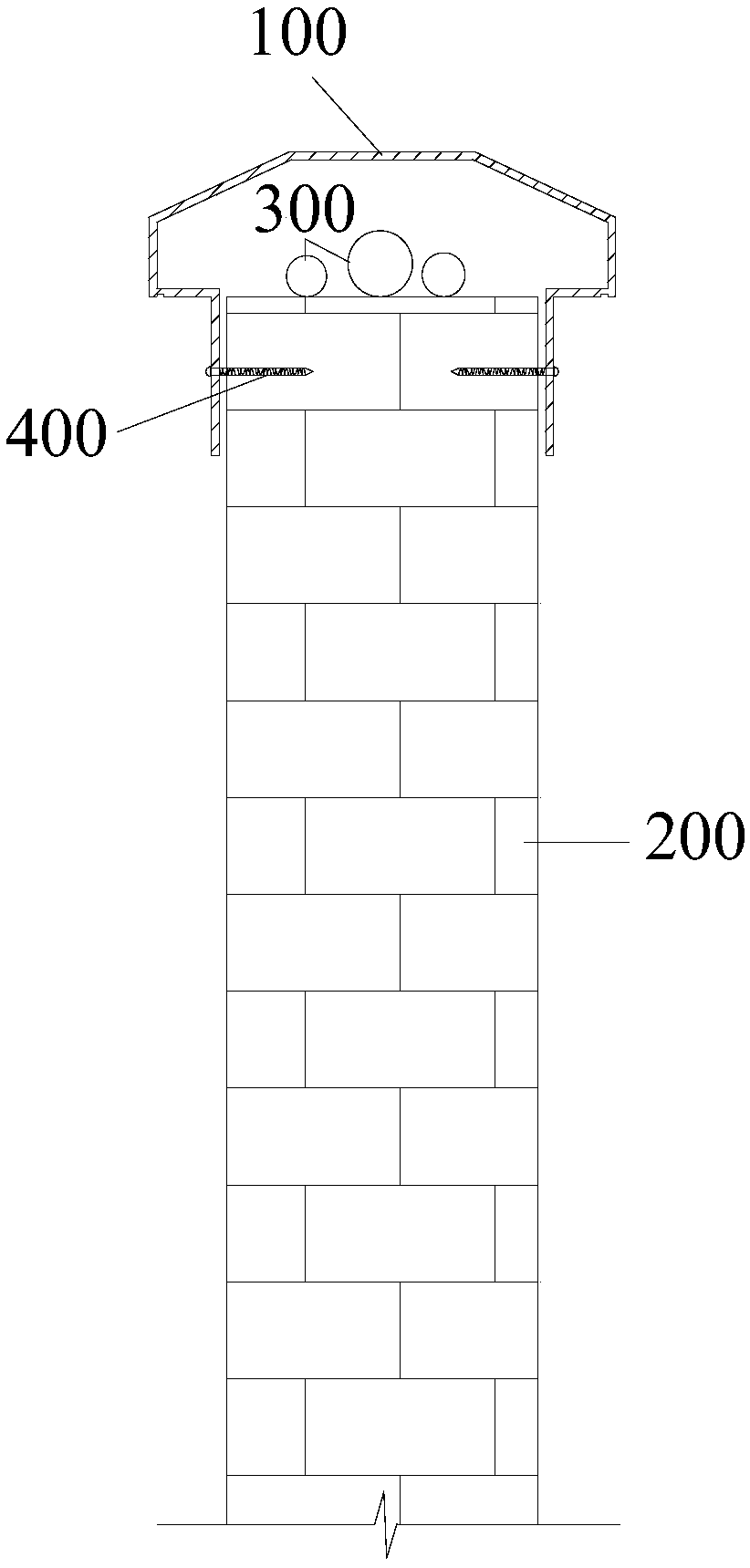

[0036] Please refer to Figure 1 to Figure 4 The second embodiment also provides a construction method of the prefabricated enclosure wall 100 in the first embodiment above,

[0037] A certain section of prefabricated enclosure wall pressing top 100 is sleeved and installed on the top of enclosure wall 200 through a fixing plate 105;

[0038] A section of the prefabricated wall top 100 in the adjacent section of the prefabricated wall top 100 is partially overlapped on another section of the prefabricated wall top 100;

[0039] Seal the gap between the prefabricated enclosure wall pressing top 100 in the overlapping part of adjacent sections;

[0040] The fixing plate 105 is fixed on the enclosure wall 200 by a fastener 400. The fastener 400 is, for example, a screw.

[0041] The construction method of the prefabricated enclosure wall pressing top 100 provided in the second embodiment is directly sleeved on the top of the enclosure wall through the fixing plate 105, and then fixed by ...

Embodiment 3

[0044] The third embodiment provides a method for manufacturing the prefabricated wall pressing top 100 of the above-mentioned first embodiment, and the prefabricated wall pressing top 100 is formed integrally by using plastic plates.

[0045] For example: using white resin material, pressed by the mold factory, height 100mm, width 280mm (specific size can be customized according to site needs), the position of the drip tank must be left during processing, and the pressing length is 2m, which is convenient for on-site installation. Warehouse storage.

[0046] Before site installation, the enclosure wall needs to be built to the height required by the design. Painted and leveled on both sides of the enclosure wall, after reaching 75% strength, start to install the hard plastic compression roof, and fix it on the enclosure wall with long screws every 200mm, each section of the hard plastic compression roof They are connected by lap joints, and the lap width of the adjacent two sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com