A Method for Prevention and Control of Rockburst in Shuangshangshan Mining

A rockburst and mine room technology, applied in ground mining, earthwork drilling, underground mining, etc., can solve problems such as hidden dangers of production safety, complicated construction process, especially severe rockburst phenomenon, etc., to ensure production safety and reduce safety risks. , the effect of improving resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

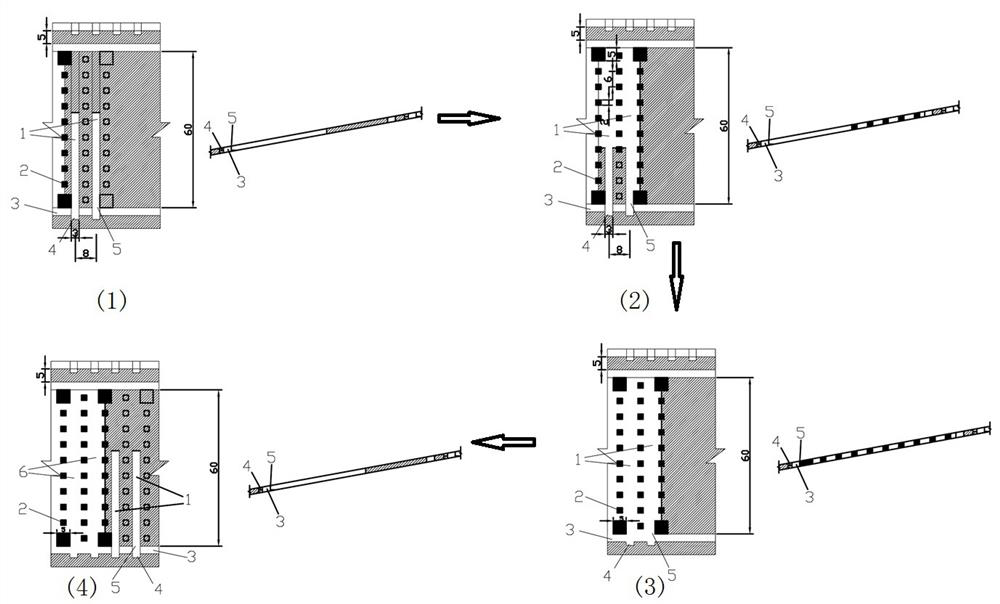

[0023] In view of the fact that the roof of the lower phosphorus layer in Yichang is medium-thick dolomite and gray dolomite interbedded with psynonymous phosphorite, argillaceous psynonymous phosphorite strips or sandy debris, the rockburst phenomenon is remarkable at the burial depth of 200-450 meters. By changing the traditional technology, using the double-uphill excavation method to release the stress on the surrounding rock evenly at multiple points, reduce the degree of rockburst, improve the construction safety factor, reduce the difficulty of construction, and make effective use of mineral resources.

[0024] First: Arrange the mine house in the opposite direction in the thin ore body block, and simultaneously excavate two cuttings up the mountain on both sides of the mine house. Control the distance between the two uphills to be 6 meters, the width of the uphill is 3 meters, and the height is based on the thickness of the rich ore. Take the rich ore at one time, gener...

Embodiment 2

[0029] Example 2: Sujiapo Phosphate Mine is a typical sedimentary deposit with a burial depth of about 500 meters. The main out-of-vein development projects have been completed. Most of the middle-section development roadways are arranged along the veins. The single-headed excavation distance is long, and rockbursts are common. The tunneling speed is less than 40 meters per month. After the successful construction technology test of the double-up hill, try to construct the double-level lanes along the main road at the same time. It not only solved the severe rockburst in the double roadway, but also solved the problem of long-distance ventilation and the requirements for meeting cars, and achieved a good performance of 80 meters in monthly excavation. Since the roadway is constructed along the vein, the ore belt during the excavation can offset the construction cost, and it is now widely used in the excavation and excavation along the vein.

Embodiment 3

[0030] Example 3: The Yangliu Phosphate Mine, also in Yichang, is a super-large mine with a design of 4 million tons per year. It is now under construction. It is also a typical sedimentary deposit with a buried depth of 800 meters. The rockburst phenomenon is more severe. All protection methods have been tried, but the excavation speed is difficult to meet the planning requirements. After exploring the double uphill layout of the excavation construction, the rockburst has been significantly improved, and the alternate parallel construction has achieved a monthly progress of 75 meters. The progress of the project is 3 excavation cycles every two days. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com