A structure and method for realizing deep and high ground stress release based on phase change oriented pre-cracking

A technology of high in-situ stress and stress-relief holes, which is used in earth-moving drilling, wellbore/well components, mining equipment, etc. It can solve the disturbance of surrounding rock, increase the drilling density, and cannot strictly control the hole depth and blasting depth, etc. problem, to achieve the effect of increasing rock drilling rate and reducing rock burst

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto.

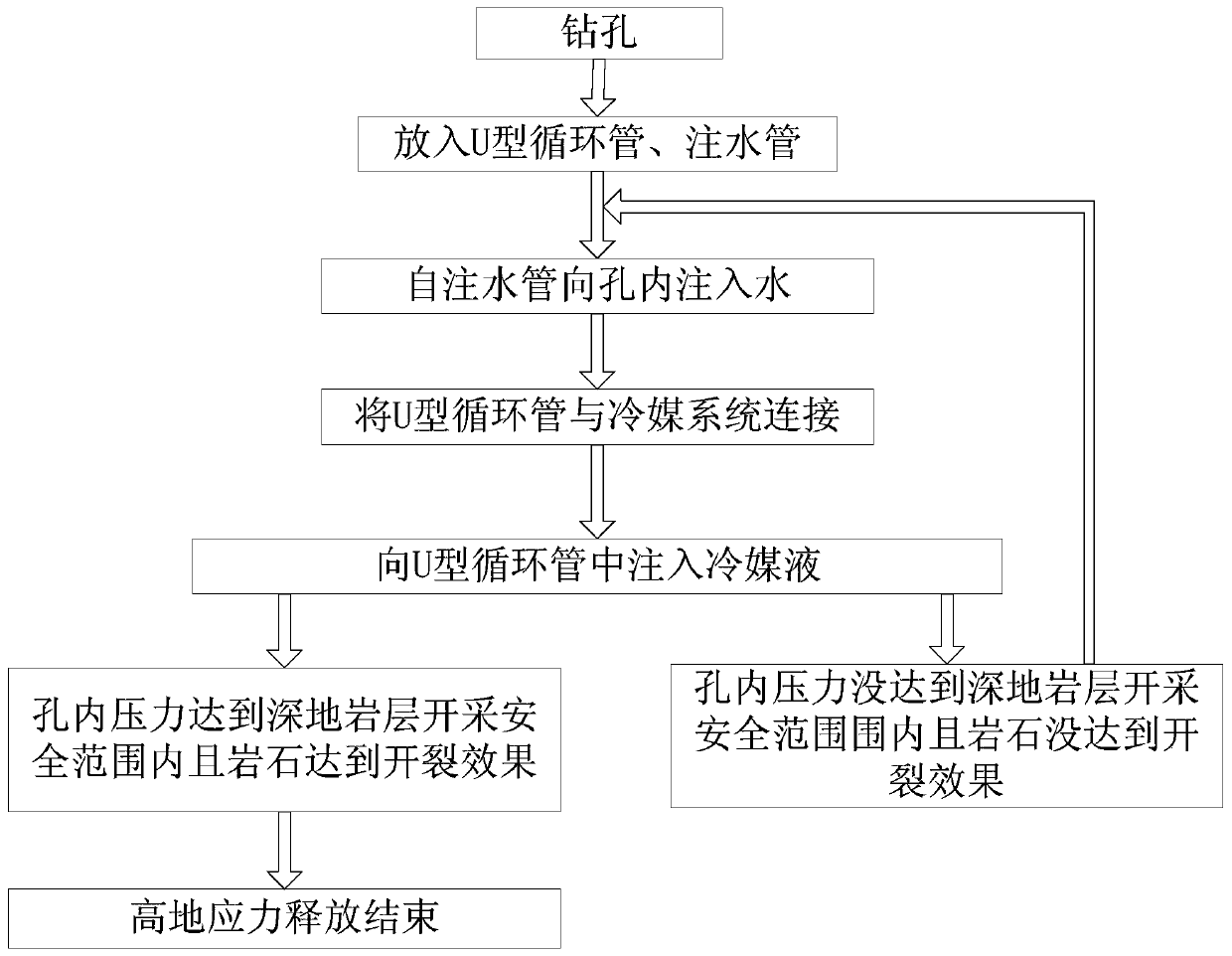

[0032] This embodiment provides a safe, efficient and fast method for releasing deep rock drilling prestress, including the following steps:

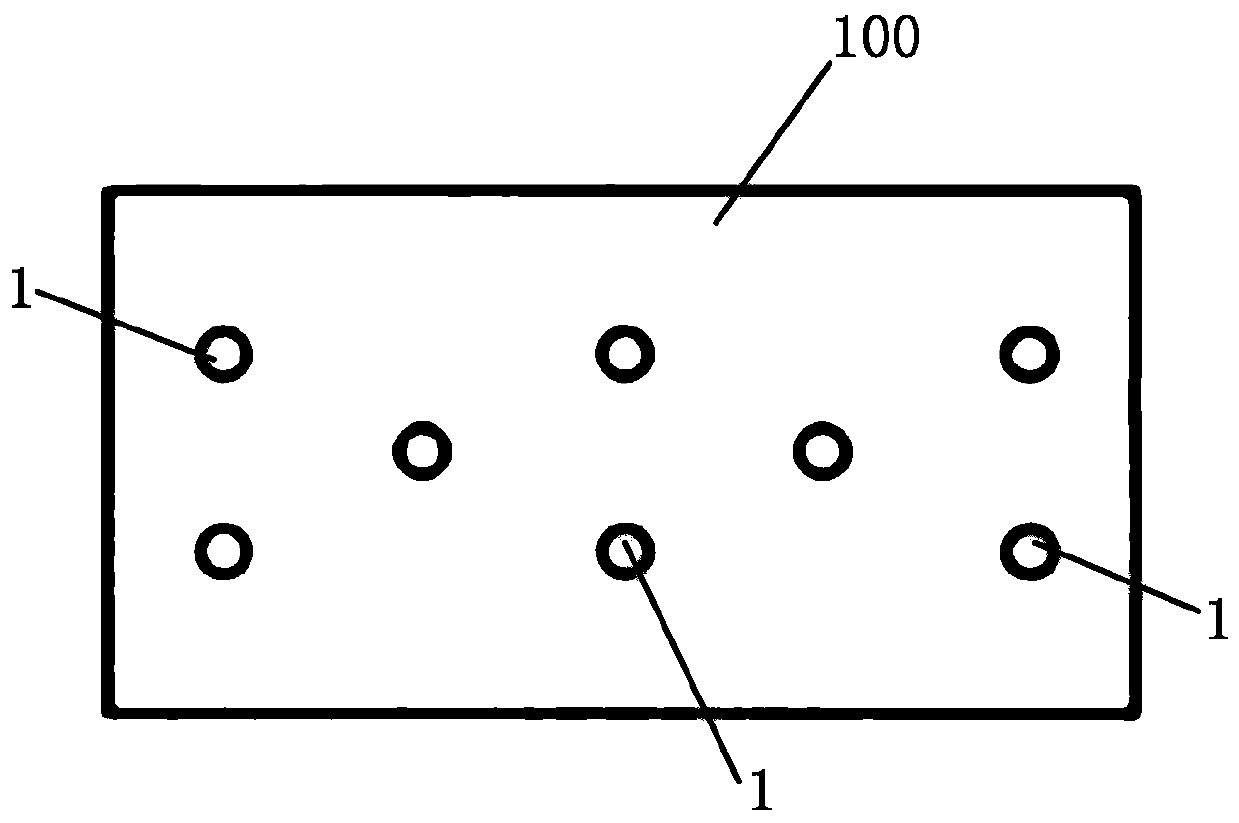

[0033] Step 1. Using a rock drilling rig to open a plurality of stress relief holes 1 in the rock formation 100, the plurality of stress relief holes 1 are arranged in five patterns or in the shape of a meter;

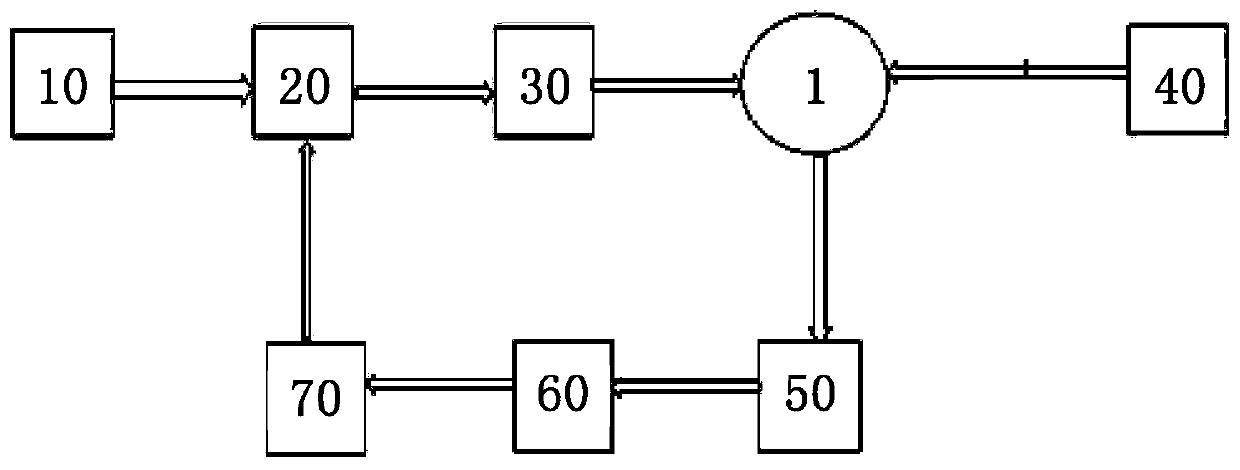

[0034] Step 2: On the surrounding wall of the induction ring 4, open a plurality of through holes for the sensing head to protrude from. The inner cavity of the induction ring 4 is equipped with a temperature sensor and a pressure sensor, and then the induction ring 4 is fixed on the U-shaped circulation pipe. 2, to realize the real-time collection of the temperature and pressure of the water in the stress relief hole 1; insert a U-shaped circulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com