Muddy water circulating system for shield tunneling machine

A technology of shield machine and muddy water, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as inability to discharge slurry, poor flow, and easy accumulation of mud and slag in the air cushion warehouse, so as to prevent the stagnation of slag and soil, The effect of reducing the specific gravity and reducing the risk of surface breakdown or subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

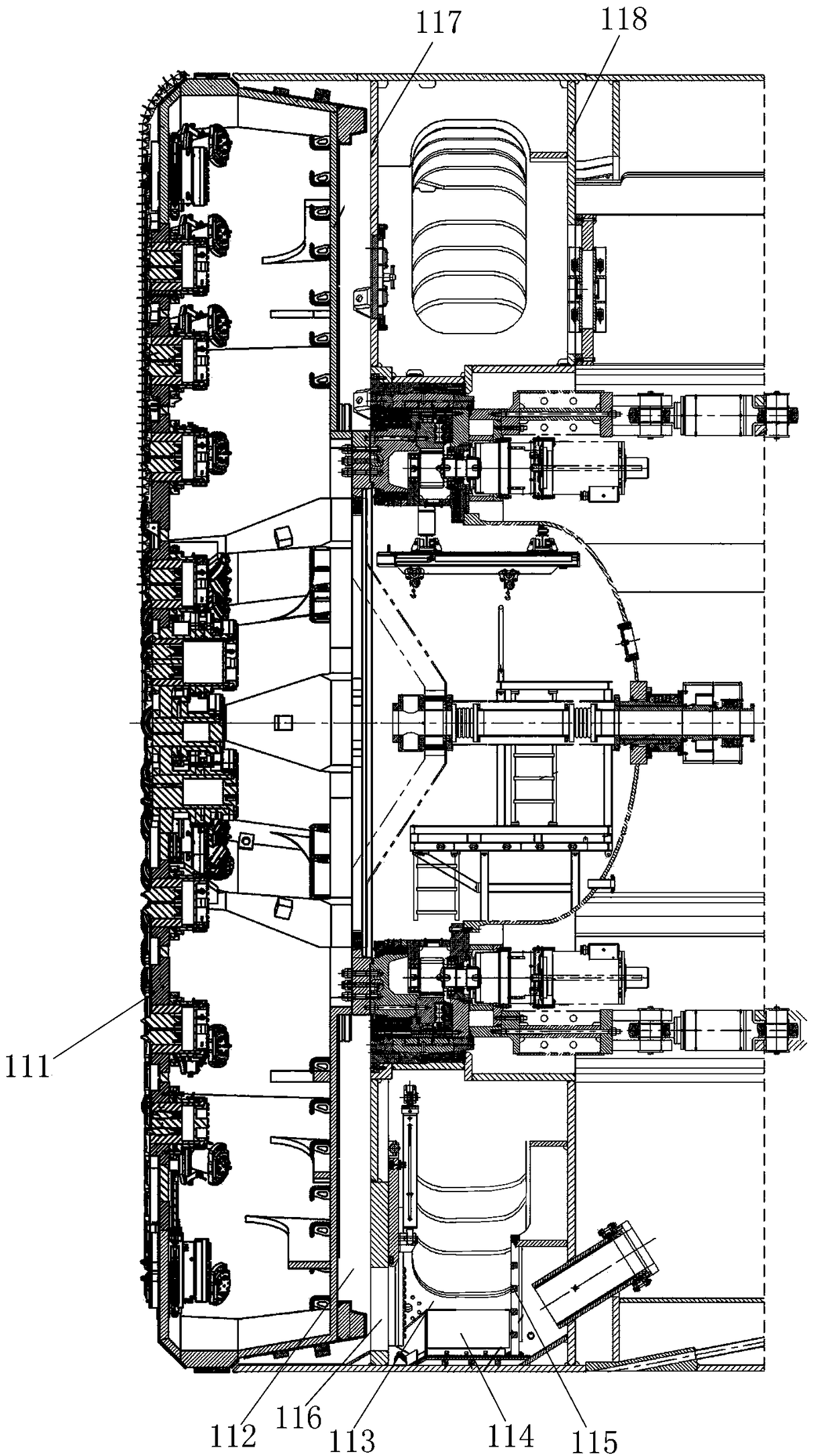

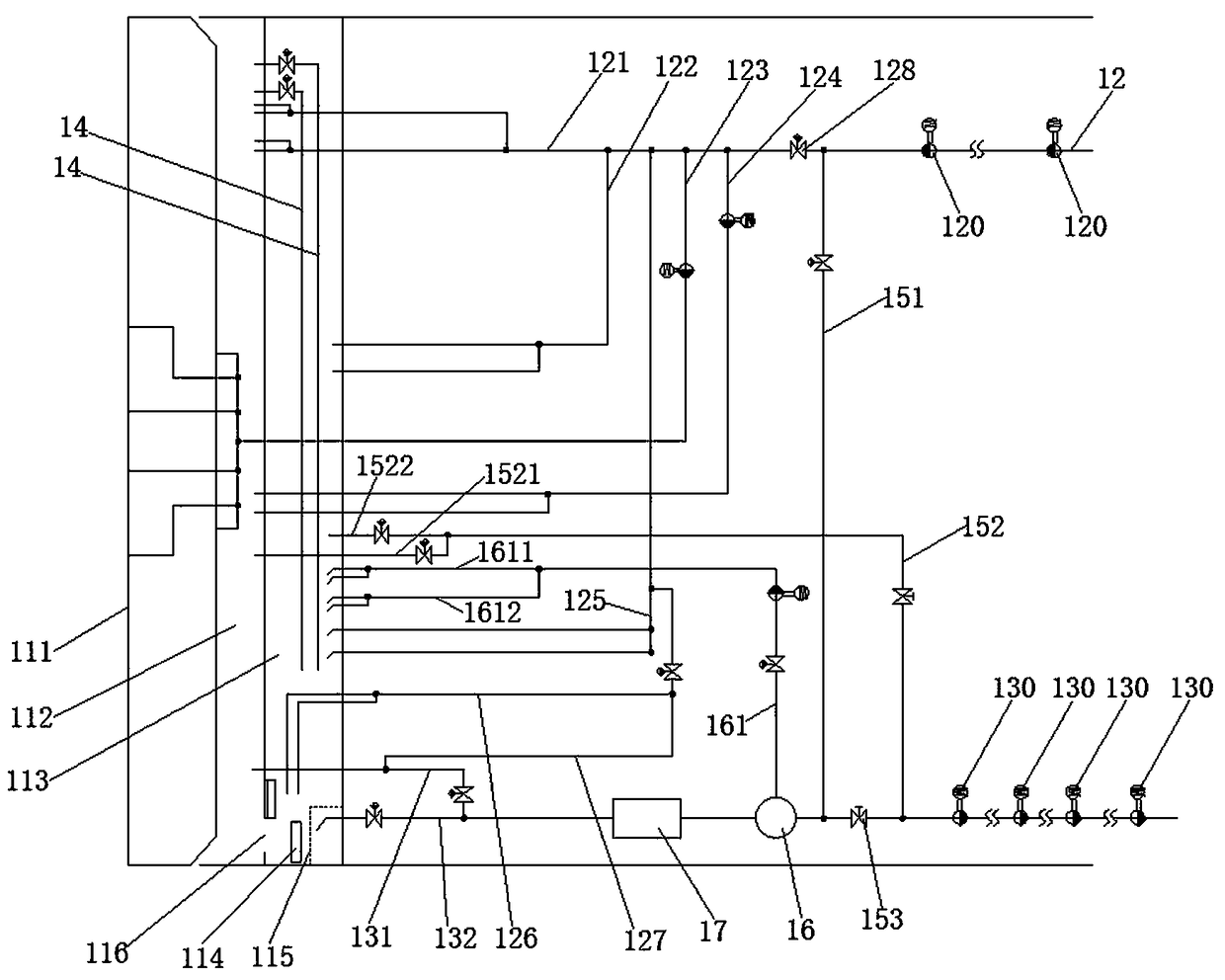

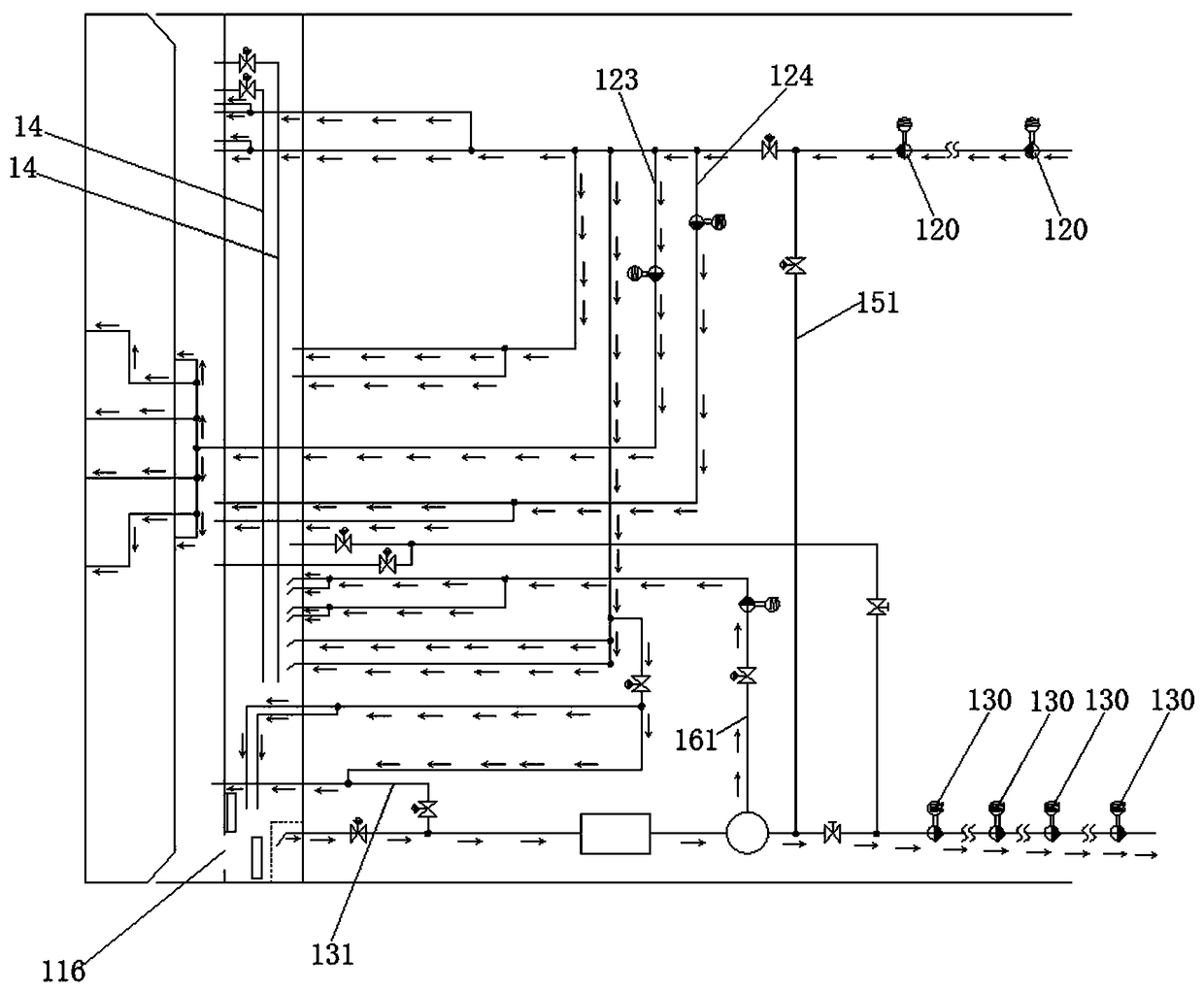

[0033] see Figure 1 to Figure 6 .

[0034] Such as figure 1 As shown, the mud-water circulation system of the shield machine provided by the embodiment of the present invention is used on the mud-water balance shield machine. The rear of the cutterhead 111 of the mud-water balance shield machine is isolated by the front partition 117 and the rear partition 118. Two internal spaces, Wherein, before the front bulkhead 117 is the mud tank 112, between the front bulkhead 117 and the rear bulkhead 118 is the air cushion warehouse 113, the bottom of the front bulkhead 117 is provided with a mud door 116, and the mud in the mud water bin 112 is passed through the mud door. 116 enters the air cushion warehouse 113, the upper half of the air cushion warehouse 113 is filled with pressurized air, the lower half of the air cushion warehouse 113 is mud, and the slurry discharge pipeline discharges the mud in the lower half of the air cushion warehouse 113 outwards, at the bottom of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com