A method of gangue filling assisting working face retraction at the final mining stage

A working face and stage technology, applied in the direction of filling, mining equipment, earth cube drilling and mining, etc., can solve the problems of difficult retraction of the working face at the final mining stage, waste rocks occupying space to pollute the environment, waste rocks occupying space to pollute the environment, etc., to achieve The effect of shortening the moving cycle, realizing multi-point operations, and increasing the speed of withdrawal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1, prefabricated block filling assists the retreat of the working face at the final mining stage.

[0038] Firstly, waste coal gangue is used to prepare prefabricated blocks for filling, and maintenance is carried out in advance, and its uniaxial compressive strength is tested to ensure that its strength is greater than the strength of the coal body mined in the working face, and then packaged and stored for use.

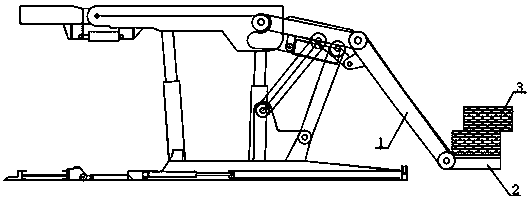

[0039] When the working face advances to the final mining stage, the prefabricated blocks are put down from the auxiliary shaft through the mine car to the yard at the bottom of the shaft, and then sent to the section return air level roadway through the main transport stone gate, and sent to the coal mining face by the belt conveyor, and finally Masonry of prefabricated blocks is carried out through the improved cover beam.

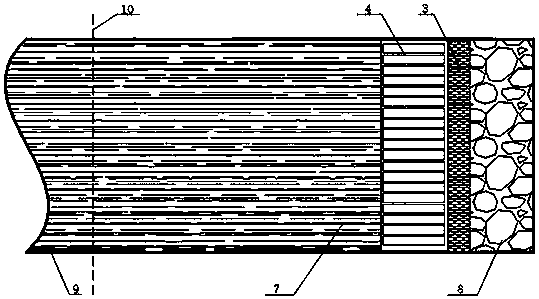

[0040] Prefabricated blocks shall be laid in ladder form before hanging net support in the impact stage of final mining, and t...

Embodiment 2

[0043] Embodiment 2, prefabricated block filling combined with a single pre-excavation withdrawal channel assists the withdrawal of the working face at the final mining stage.

[0044] Firstly, waste coal gangue is used to prepare prefabricated blocks for filling, and maintenance is carried out in advance, and its uniaxial compressive strength is tested to ensure that its strength is greater than the strength of the coal body mined in the working face, and then packaged and stored for use.

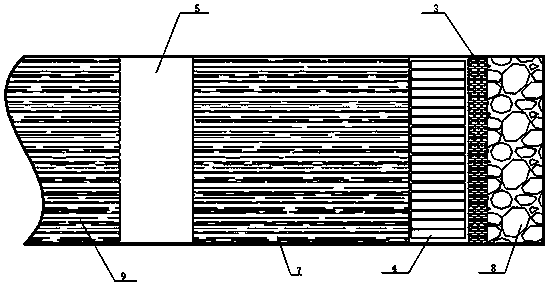

[0045] Before the start of mining at the working face, the coal body of the mining line is stopped, and a retraction channel is excavated near the side of the working face, and the surrounding rock is supported by bolts and anchor cables, and the construction of the single retraction channel is completed. .

[0046] When the working face advances to the final mining stage, the prefabricated blocks are put down from the auxiliary shaft through the mine car to the yard at the bottom of the s...

Embodiment 3

[0050] Embodiment 3, prefabricated block filling combined with double pre-excavation withdrawal channels to assist the withdrawal of the working face at the final mining stage.

[0051] Firstly, waste coal gangue is used to prepare prefabricated blocks for filling, and maintenance is carried out in advance, and its uniaxial compressive strength is tested to ensure that its strength is greater than the strength of the coal body mined in the working face, and then packaged and stored for use.

[0052] Before the start of mining at the working face, the coal body of the mining line is stopped, and an auxiliary retraction channel is excavated near the side of the working face, and an interval of coal pillars is left between the side of the working face and the auxiliary retracting channel, and another channel is excavated As the main retracement channel, the main and auxiliary retracement channels are separated by a distance between the coal pillars to excavate the connecting roadw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap