Tripod sliding type universal joint assembly

A sliding type, universal joint technology, applied in the field of auto parts, can solve the problems affecting the transmission efficiency of the whole vehicle, NVH performance and the swing angle range of the universal joint, large friction resistance, large contact area, etc. High efficiency, large working swing angle, and the effect of increasing the swing angle range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described

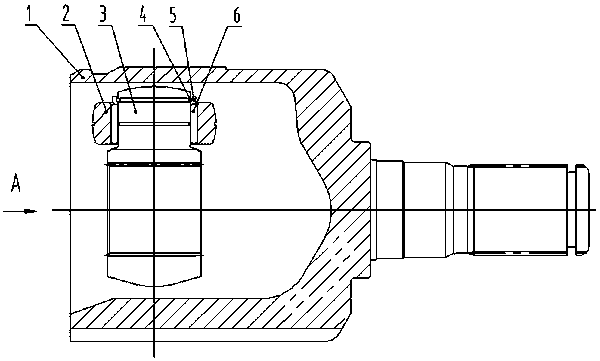

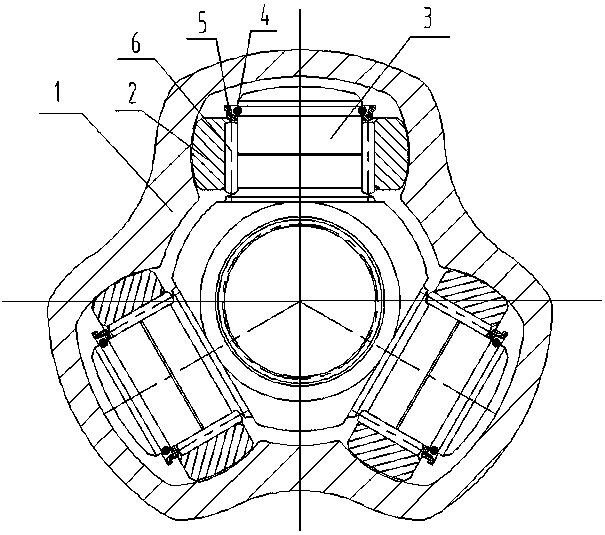

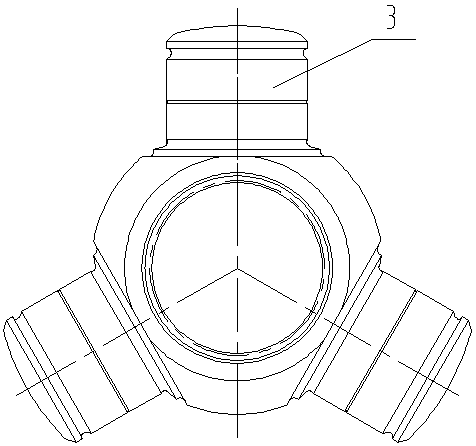

[0013] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown, this embodiment includes a sliding sleeve 1 and a trident bearing assembly arranged in the inner cavity of the sliding sleeve 1 . The sliding sleeve 1 is provided with a raceway with an arc-shaped section for the sliding of the three-prong bearing assembly. The three-prong bearing assembly includes a bearing frame 3 with an involute spline in the middle, and a bearing frame 3 uniformly arranged on the bearing frame 3. Three pin shafts, bearing outer ring 2, needle roller 6, retaining ring 4 and elastic snap ring 5 are housed on each pin shaft. The outer spherical surface of the bearing outer ring 2 matches the raceway of the sliding sleeve 1, and a groove 7 is processed on the outer spherical surface of the bearing outer ring 2 (or a rough surface etch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com