Detection method for cylinder deactivation camshaft displacement

A detection method and camshaft technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of engine cylinder deactivation technology without effective detection methods, and achieve the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

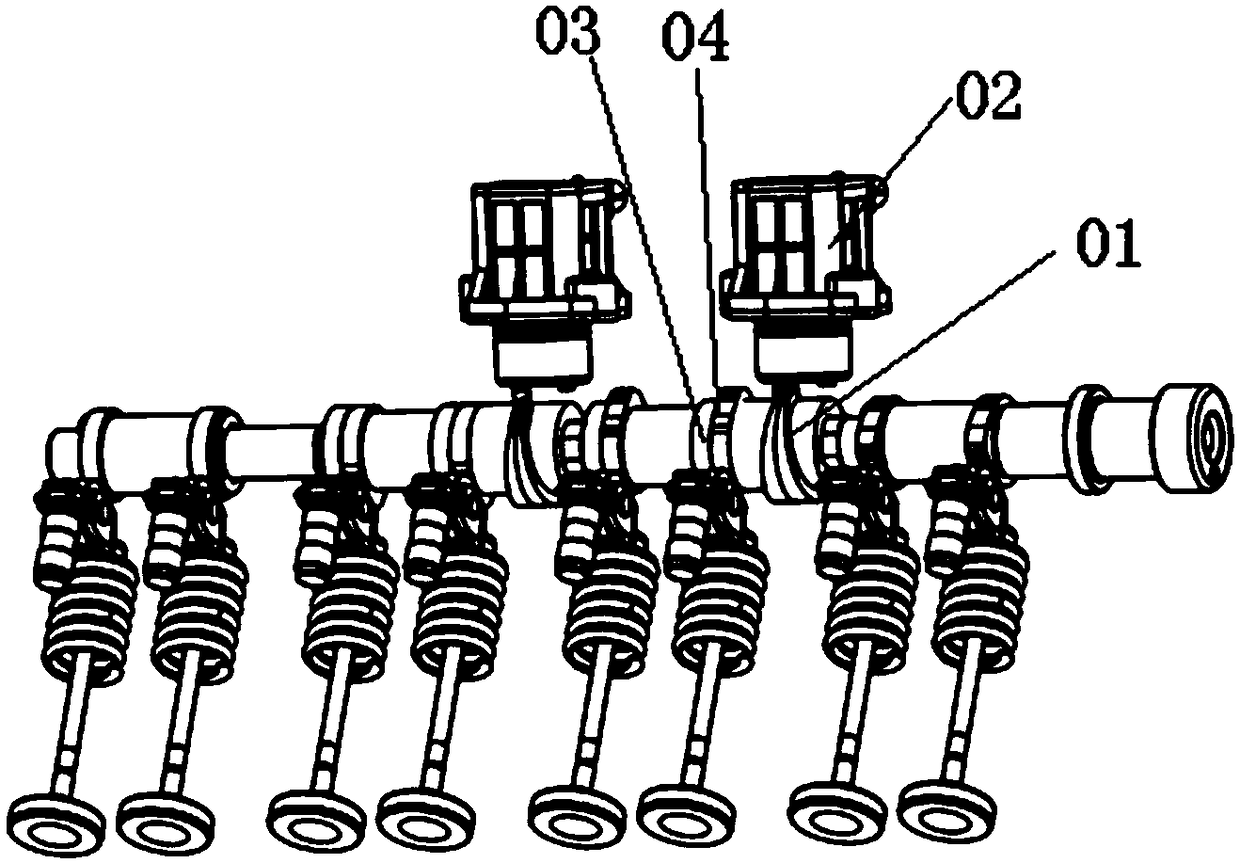

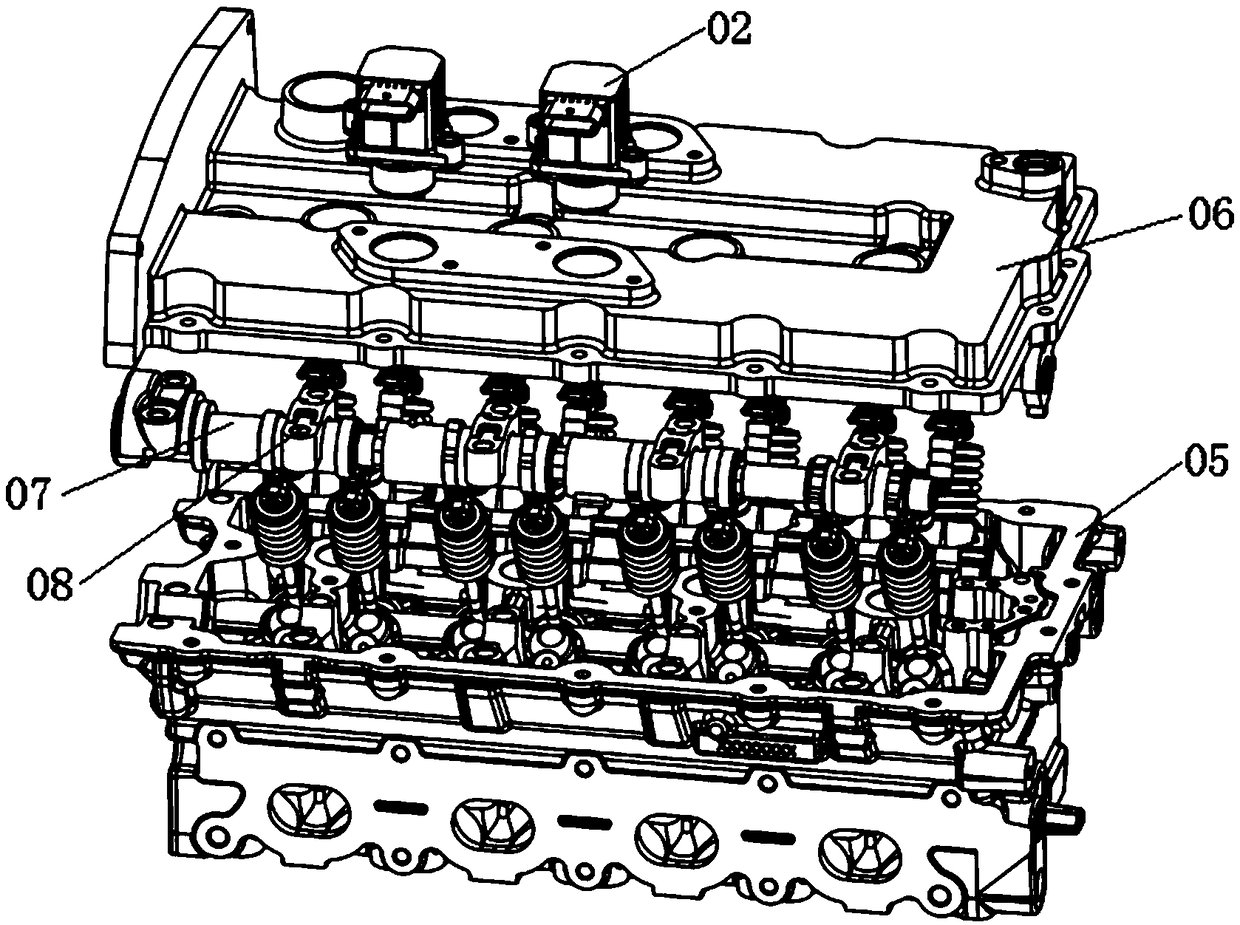

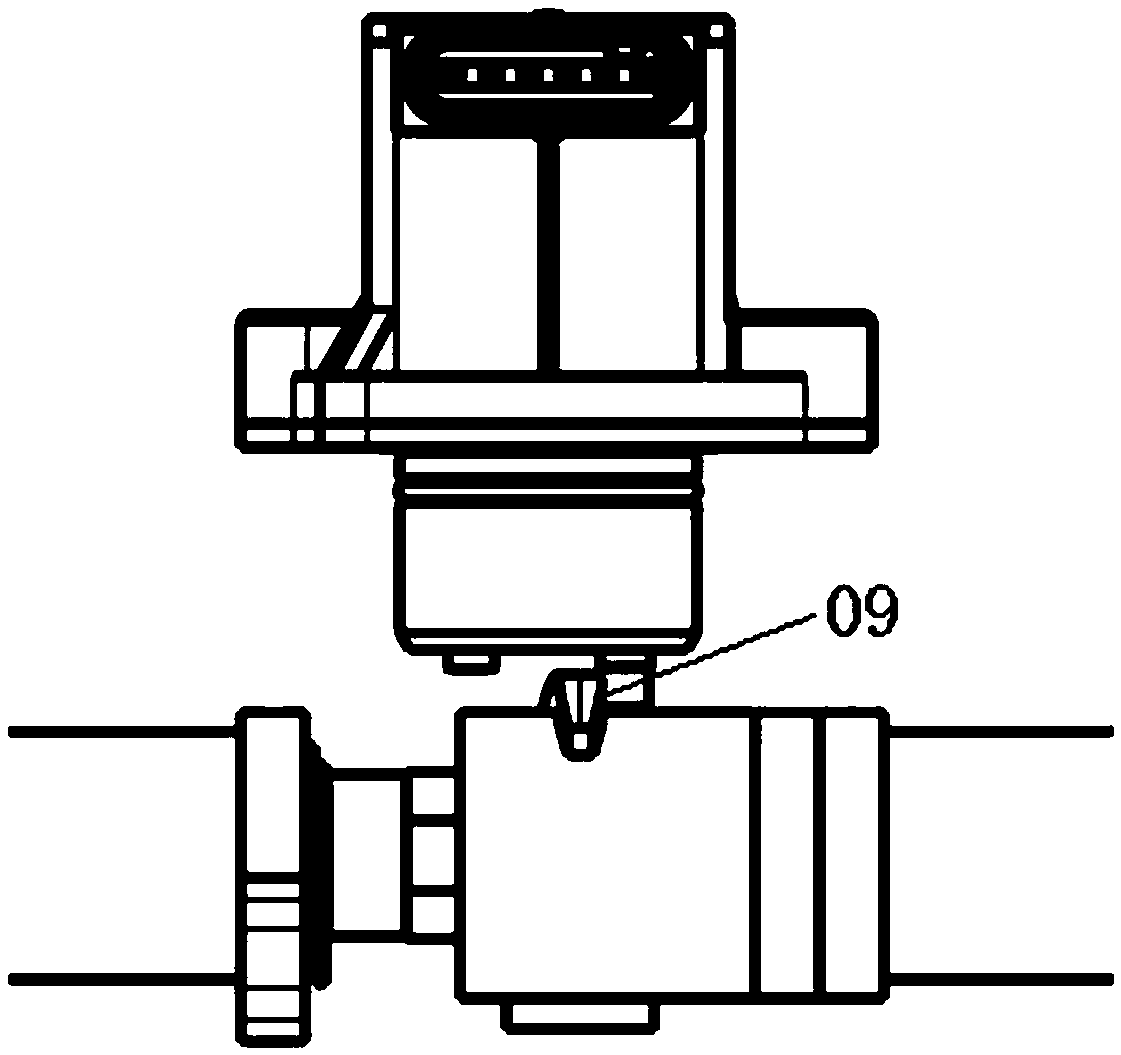

[0041] This application provides a test that can effectively detect the state of the rotation groove of the camshaft sleeve. On the one hand, the test result can be used to judge whether the cylinder head camshaft after assembly is qualified. On the other hand, the test result can be used as a control strategy for the solenoid valve pin input signal.

[0042] Such as Figure 4 to Figure 7 As shown in the static displacement detection method, the product 101 to be tested is fixed on the test platform, and the high-definition camera 102 is fixed by the tripod 103 . The tripod can be adjusted in height and angle. The displacement accurac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com