Temperature control system for high-precision pressure-resistant gas

A temperature control system and high-precision technology, applied in thermometers, thermometer testing/calibration, measuring devices, etc., can solve problems such as inability to withstand pressure, temperature uniformity cannot reach ±1°C, and gas temperature cannot be truly displayed. The effect of withstand voltage requirements, improving stability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below.

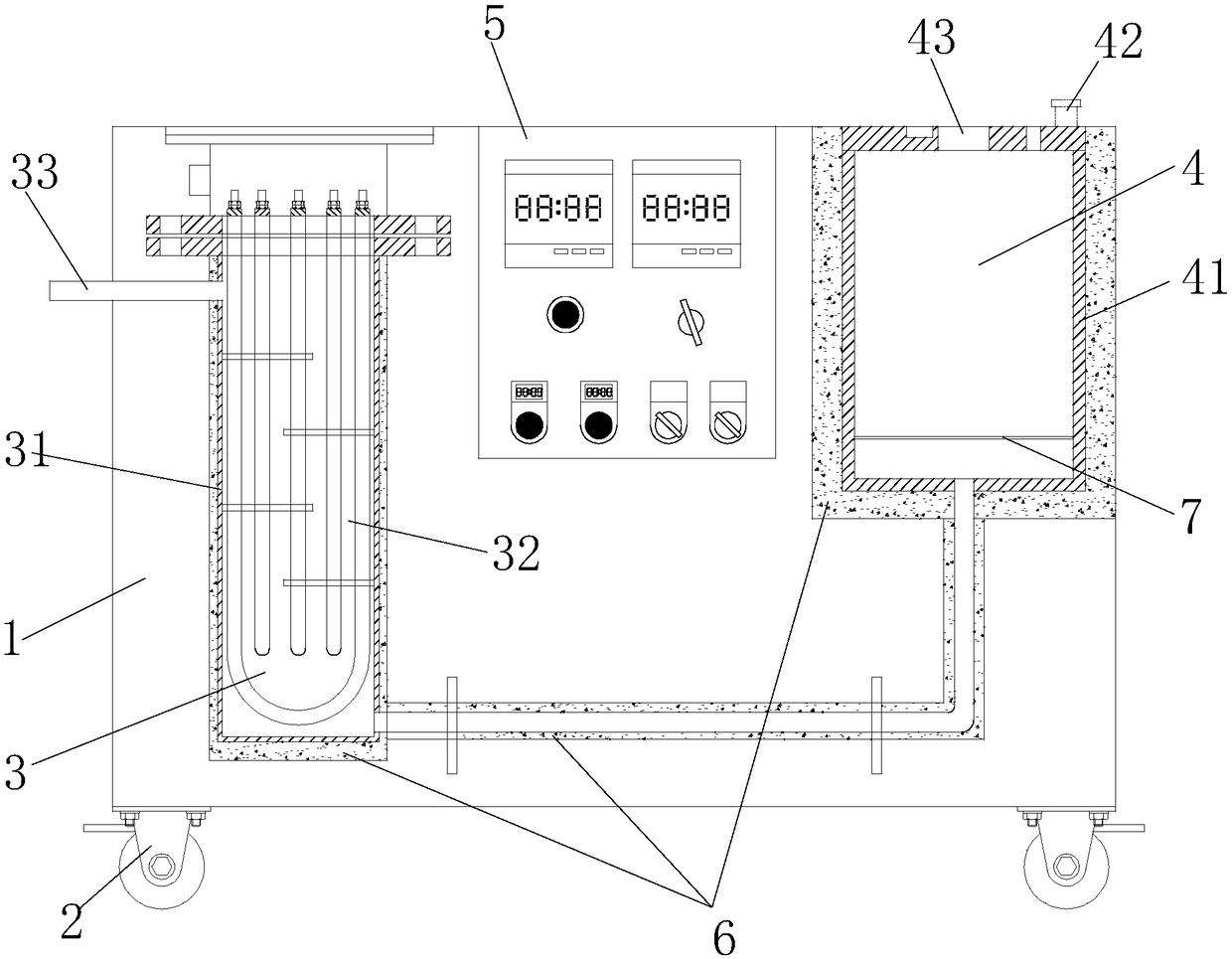

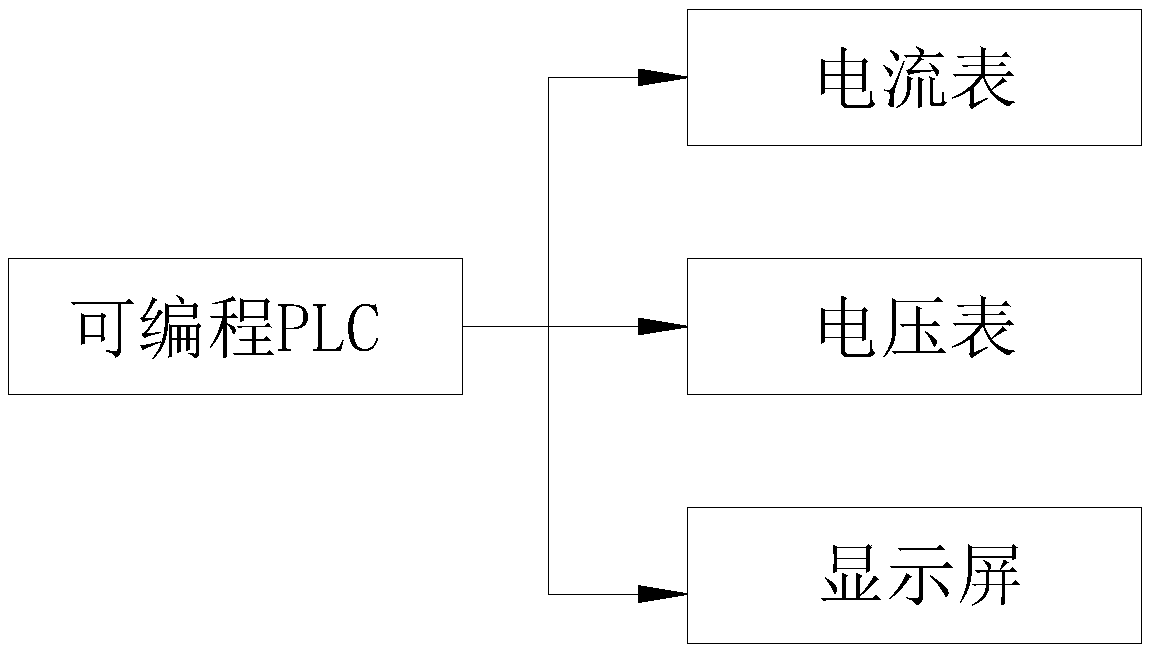

[0023] Such as Figure 1 to Figure 3 As shown, a high-precision pressure-resistant gas temperature control system includes a box body 1, a universal wheel 2 installed at the bottom of the box body 1, and a heating chamber 3 through which compressed gas is introduced and heated. The test cavity 4 where the test piece is installed, the heating cavity 3 and the test cavity 4 are connected by a pipe, and the box body 1 is provided with a control system 5 connected to the heating cavity 3 and the test cavity 4.

[0024] The heating chamber 3, the test chamber 4, and the pipe are all wrapped with an insulation layer 6, which is made of asbestos material and has a thickness of not less than 50mm.

[0025] The heating chamber 3 includes a heating box 31 in which an electric heating element 32 connected to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com