A method of constructing 3D mesh model of large underground engineering under complex geological conditions

A complex geological condition and grid model technology, applied in the field of 3D grid model construction, can solve the problems of time-consuming and laborious establishment of 3D grid model for large underground engineering, complex shape of 3D geometric model, poor quality of grid division, etc. Achieve the effects of reducing modeling workload, reducing the total number of grid units, and ensuring grid quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

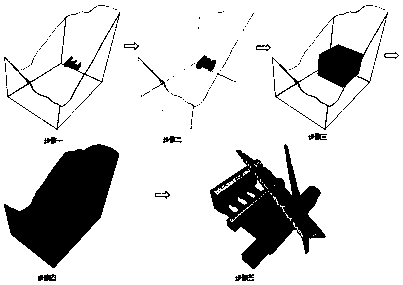

Embodiment 1

[0034] see figure 1 , in this software, the core command flow to realize step 5 is: group f1 ran plane dd 191dip 48 ori 271.769050, 734.759597, 2264 dist 1.0 group 35, the italics in the command flow are command keywords, and the subsequent parameters can be changed according to the actual situation. The situation is modified, the meaning of this command is: the group name is 35 points (271.769050, 734.759597, 2264), the inclination angle of 191°, the inclination angle of 48°, and the grids within the distance of 1.0m above and below the normal direction of the plane are returned to for group f1. According to this command format, you can continue to add other occurrences of discontinuous surfaces in the constructed FLAC3D3D mesh model.

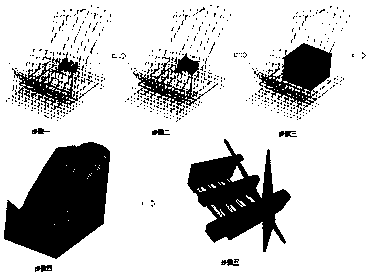

Embodiment 2

[0036] see figure 2 , in this software, the specific steps to realize step five are:

[0037] ① Create key points: K, NPT1, X1, Y1, Z1; ... K, NPT2, X2, Y2, Z2; NPT3, X3, Y3, Z3 (any 3 points in the discontinuous plane can be taken, NPT1- NPT3 is the number of the point, X1-X3, Y1-Y3, Z1-Z3 are the coordinates of the point, which can be modified according to the actual situation);

[0038] ②Move the working plane: KWPLAN, WN, NPT1, NPT2, NPT3 (move the working plane to the above key point, and its Z axis is parallel to the normal direction of the discontinuous surface);

[0039] ③Create a local coordinate system: CSWPLA, 11, 0, 1, 1, (Create a local coordinate system with the coordinate system number 11 based on the coordinate origin of the above work plane as the origin. The number can be modified according to the actual situation, but the value must be greater than or equal to 11) ;

[0040] ④ Activate the current local coordinate system: CSYS, 11,;

[0041] ⑤ Select th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com