A crosslinked elastomer insulation sheath new energy vehicle internal high-voltage cable

A technology of new energy vehicles and insulating sheaths, applied in the direction of insulated cables, insulated conductors, cables, etc., can solve the problems of excessive cable outer diameter, uneven circuit arrangement, poor heat resistance of cables, etc., to improve heat resistance performance, internal ambient temperature equalization, effects of avoiding natural phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

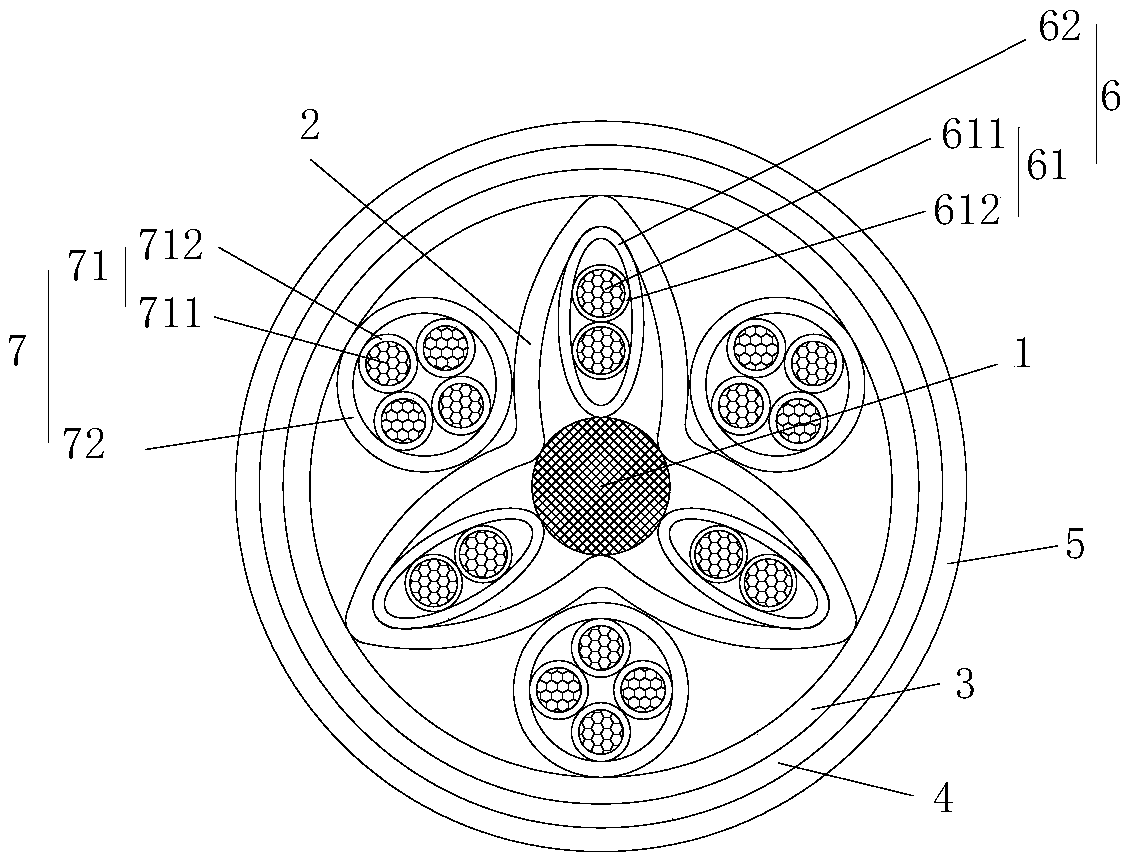

[0011] Such as figure 1 as shown, figure 1 It is a schematic structural diagram of a cross-linked elastomer insulating sheath for a new energy vehicle internal high-voltage cable proposed by the present invention.

[0012] refer to figure 1 , the present invention proposes a cross-linked elastomer insulating sheath new energy vehicle internal high-voltage cable, including a central high-temperature-resistant skeleton 1, a heat-insulating tube 2, a high-temperature-resistant layer 3, a total shielding layer 4, and an outer sheath 5; wherein :

[0013] The central high-temperature-resistant framework 1 is set inside the heat-insulating pipe 2. The heat-insulating pipe 2 includes a plurality of V-shaped sections that are distributed around the central high-temperature-resistant framework 1 and are connected to each other. The V-shaped openings of the V-shaped sections face the central high-temperature resistant Skeleton 1, the joints of two adjacent V-shaped sections abut agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com