Continuous automatic rotary rectangular tunnel furnace made of magnetic materials and production method of continuous automatic rotary rectangular tunnel furnace

A magnetic material, automatic rotation technology, applied in furnaces, furnace types, heat treatment furnaces, etc., can solve the problems of small footprint, uneven temperature, and high economic costs, saving production costs and avoiding potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

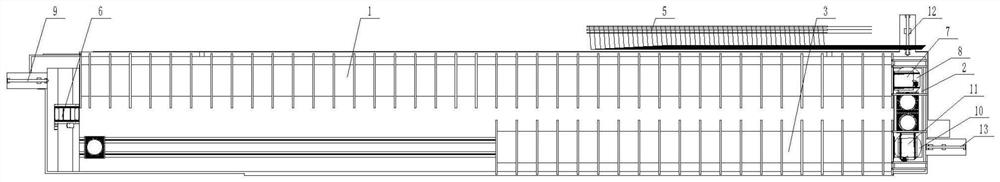

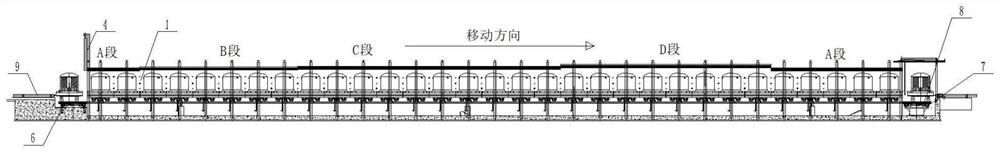

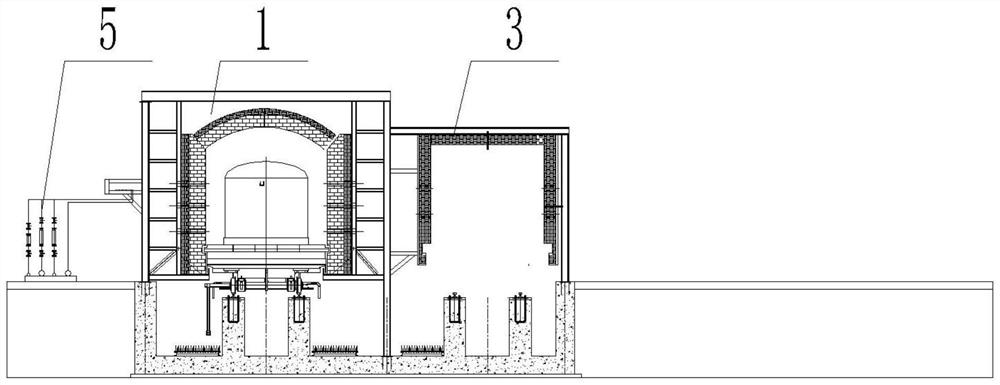

[0045] like Figure 1 ~ Figure 4 It shows that the invention is a rectangular tunnel furnace of the magnetic material, including the first vertical furnace body 1. The first vertical furnace body 1 represents different temperature interval, and the temperature of sections A, B, C section, and D sections increases in turn. Section A, B, C, C, and D section of the vault height increased in order;

[0046] Also include, horizontal furnace body 2 and second vertical furnace body 3, which are the first vertical furnace body 1., horizontal furnace body 2, and second vertical furnace body 3 are rectangular. In the first vertical furnace body 1, and the second vertical furnace body 3 is shorter than the first vertical furnace body 1, the horizontal furnace body 2 is perpendicular to the first vertical furnace body 1 and the second vertical furnace 3 settings. One end of the horizontal furnace body 2 is connected to the A paragraph at the tail end of the first vertical furnace body.

[0047...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com