An extrusion-resistant and high-temperature-resistant multifunctional cable for aviation

An extrusion-resistant and high-temperature-resistant technology is applied in the field of extrusion-resistant and high-temperature-resistant multifunctional cables for aviation. It can solve problems such as thick extrusion, poor safety and reliability, and heavy weight, and achieve radial force and environmental protection. Effect of temperature balance and improvement of extrusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

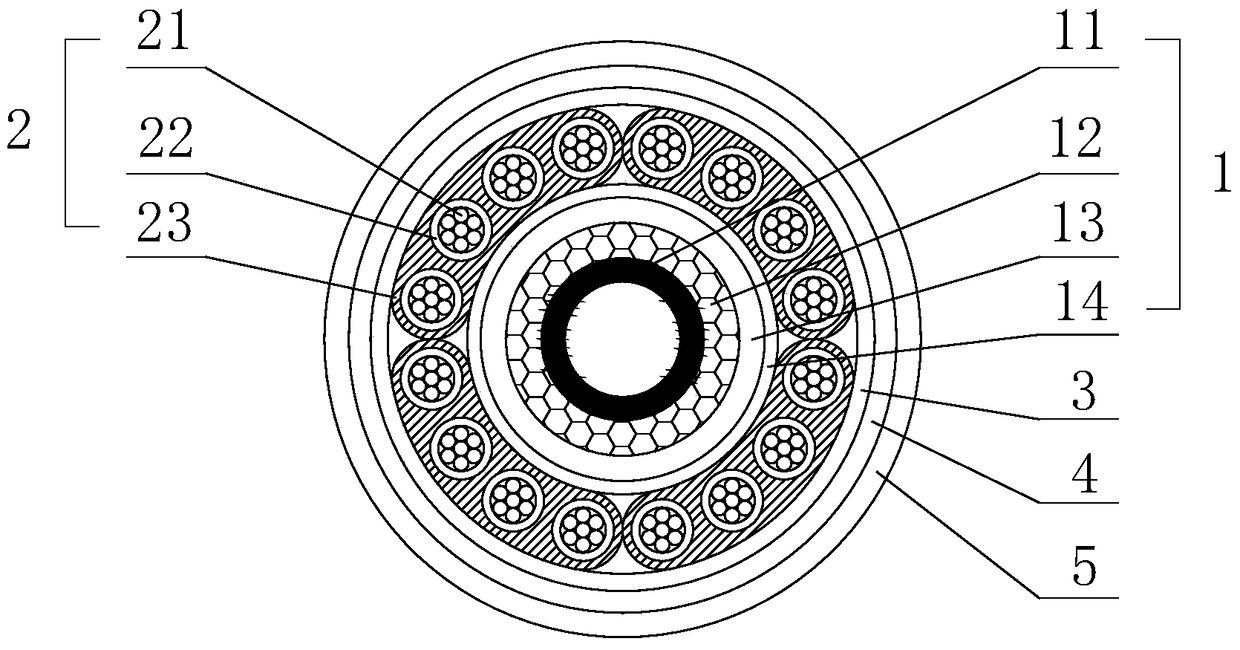

[0014] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an extrusion-resistant and high-temperature-resistant multifunctional cable for aviation proposed by the present invention.

[0015] refer to figure 1 , an extrusion-resistant and high-temperature-resistant multifunctional cable for aviation proposed by the present invention, including a cable core, a wrapping layer 3, a shielding layer 4, and a sheath layer 5;

[0016] The above-mentioned cable core includes a wire 1 and four signal wires 2. The wire 1 includes an insulating support tube 11 located in the middle. The insulating support tube 11 is made of thermoplastic elastomer material. Copper wires are wound to form a conductor layer 12, thereby forming a circular cross-section. Utilizing the principle of the skin of the copper conductor, while ensuring the electrical conductivity of the cable, the amount of copper used is reduced, and the total weight of the cable is reduced. In addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com