Blade cooler and preparation system of cellosilk

A blade cooling and blade technology, which is applied in the field of cooling devices and fiber filament preparation systems, can solve the problems of short service life of blade coolers, easy internal corrosion of blades, corrosion of blades, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

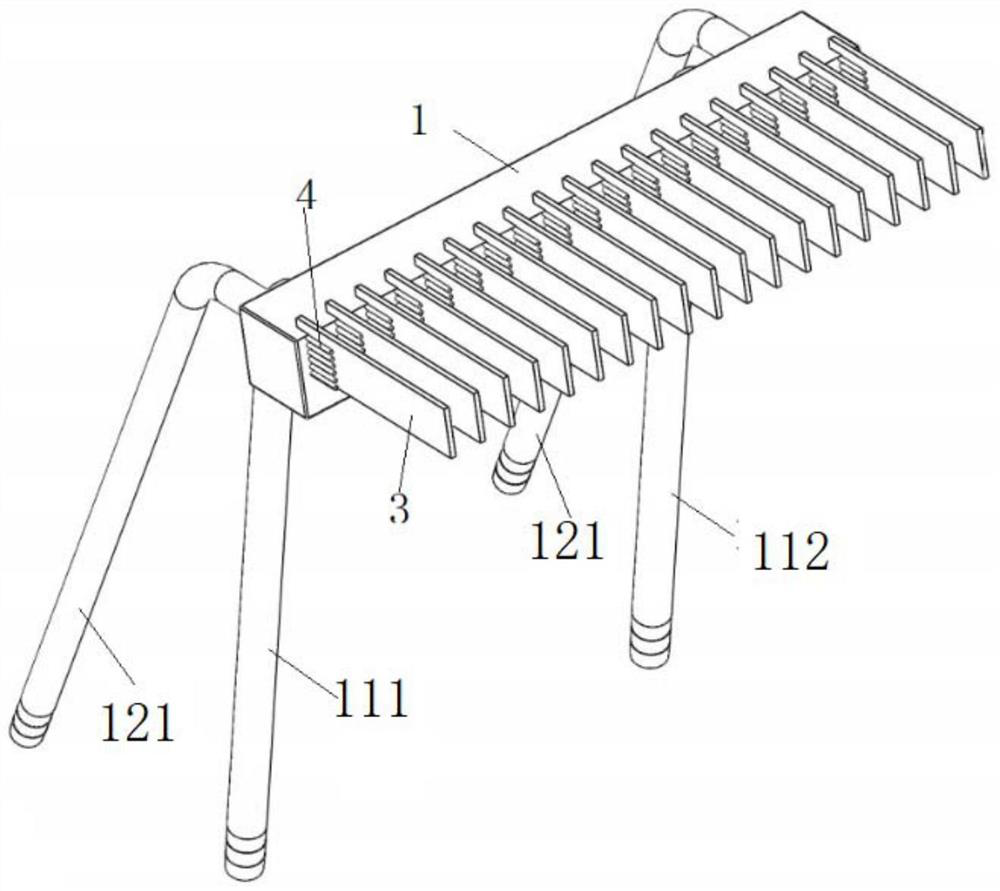

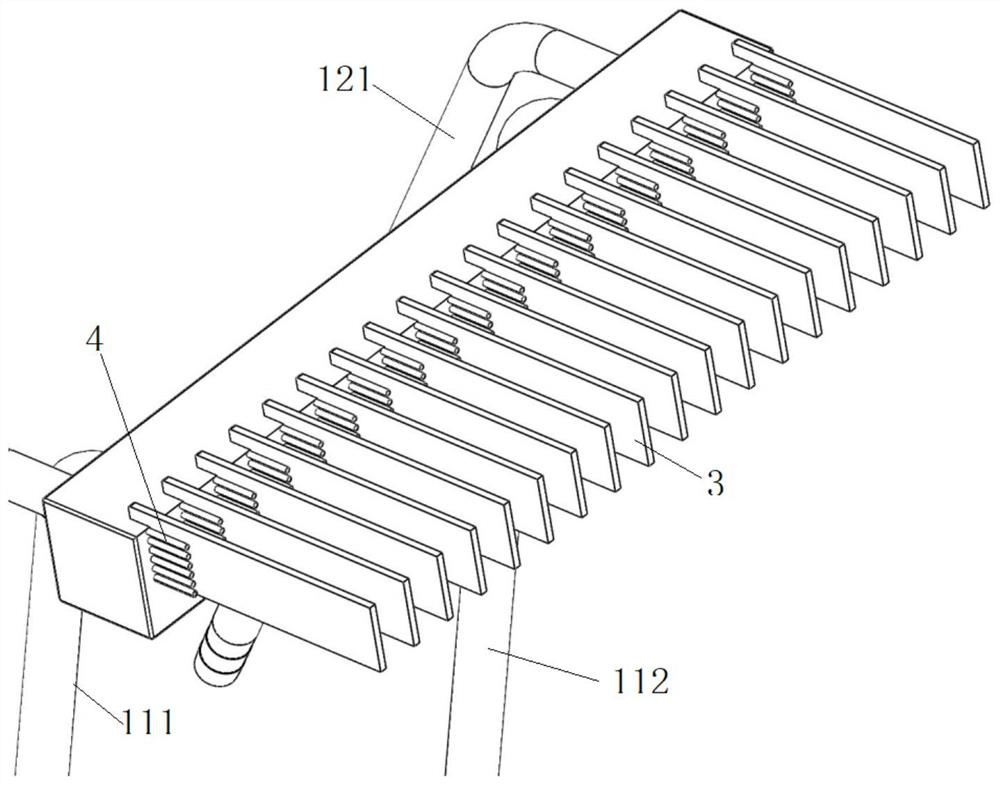

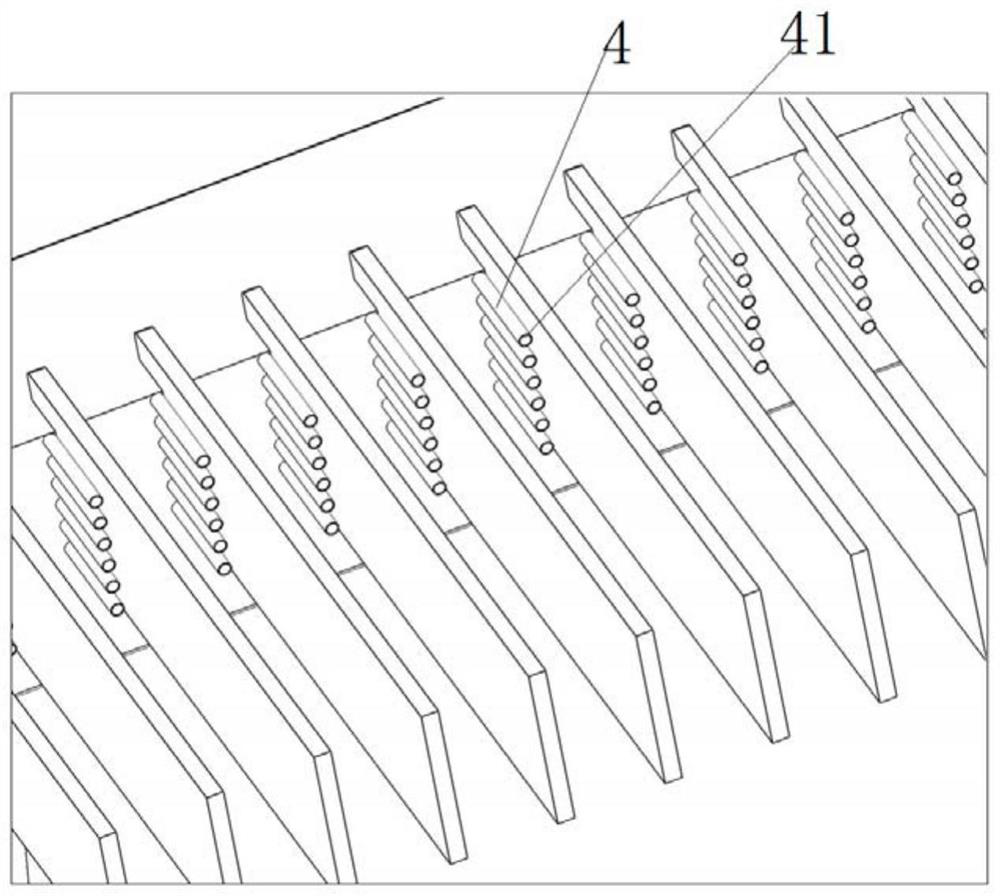

[0049] This embodiment provides a blade cooler, such as Figure 1 to Figure 9 As shown, it includes a base 1 , at least two solid blades 3 , an air outlet component 4 , an air supply mechanism 2 and a liquid supply mechanism 5 .

[0050] Among them, such as Figure 9 As shown, the base 1 is provided with mutually independent first passage 11 and second passage 12; the first passage 11 is for liquid circulation, and the second passage 12 is for gas circulation; the first end of any solid blade 3 is fixed on the base On the seat 1, the second end extends outward as a free end; all the solid blades 3 are arranged side by side and are distributed at intervals, and a cooling area is formed between two adjacent solid blades 3; the air supply mechanism 2 communicates with the second channel 12; the air outlet component One end of 4 is arranged on the base 1 and communicates with the second channel 12, and the other end is provided with an air outlet 41; at least one air outlet part ...

Embodiment 2

[0078] This embodiment provides a preparation system for fiber filaments, such as Figure 10 shown, including

[0079] The leaking plate 6 is funnel-shaped, and the bottom of the leaking plate is provided with several outlet holes;

[0080] For any implementation of the blade cooler provided in Example 1, the cooling area of the blade cooler is distributed directly below the wire outlet hole.

[0081] For example, if Figure 10 As shown, a plurality of nozzles 61 are arranged at the bottom of the bushing 6, and each nozzle serves as a thread outlet hole, and the plurality of nozzles 61 form a plurality of thread outlet holes. The root 71 of the fiber filament 7 is located at the bottom of the nozzle, and the fiber filament 7 is located in the cooling area between two adjacent solid blades, and is cooled down.

[0082] The fiber filament preparation system of this embodiment includes the blade cooler of any embodiment provided in Example 1, so that the fiber filament is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com