electrical connector

A technology for electrical connectors and connections, which is applied in the direction of conductive connections, connections, vehicle connectors, etc., and can solve problems such as reducing wires, poor electrical contact, and disconnected wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The description that follows shows various specific details intended to provide an improved understanding of the embodiments. Embodiments may be practiced without one or more of the specific details, or using different methods, components, materials, etc. In other instances, known structures, details of construction, materials or operations are not shown or described in detail because they may be implemented in any known manner and because they would not be within the scope of the invention when considered in isolation.

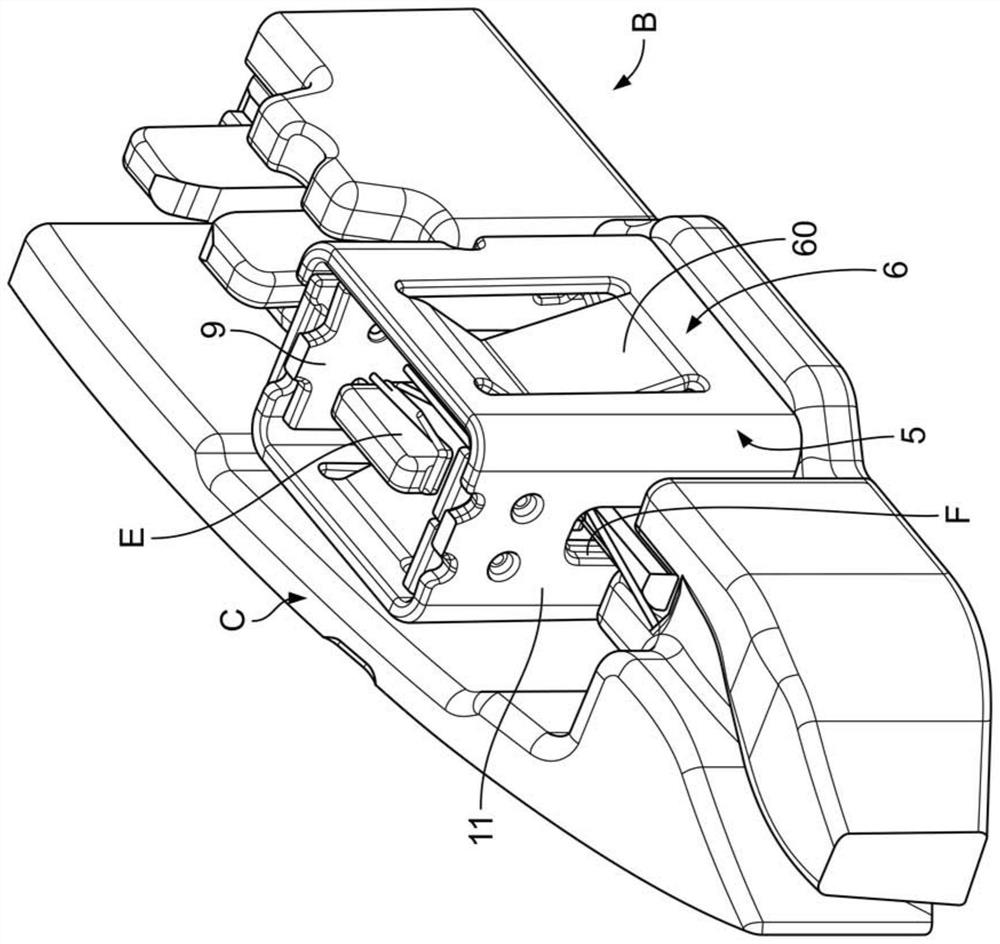

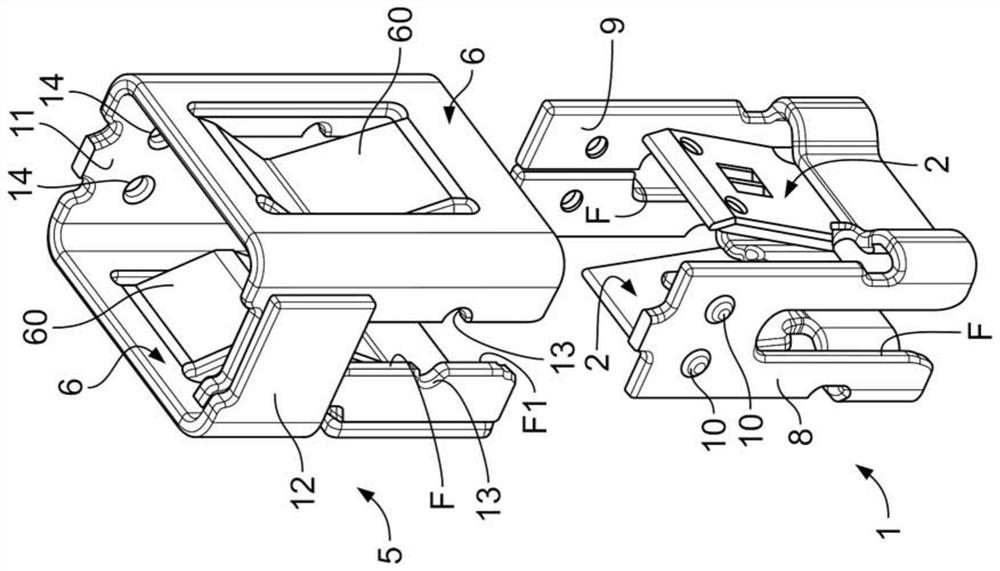

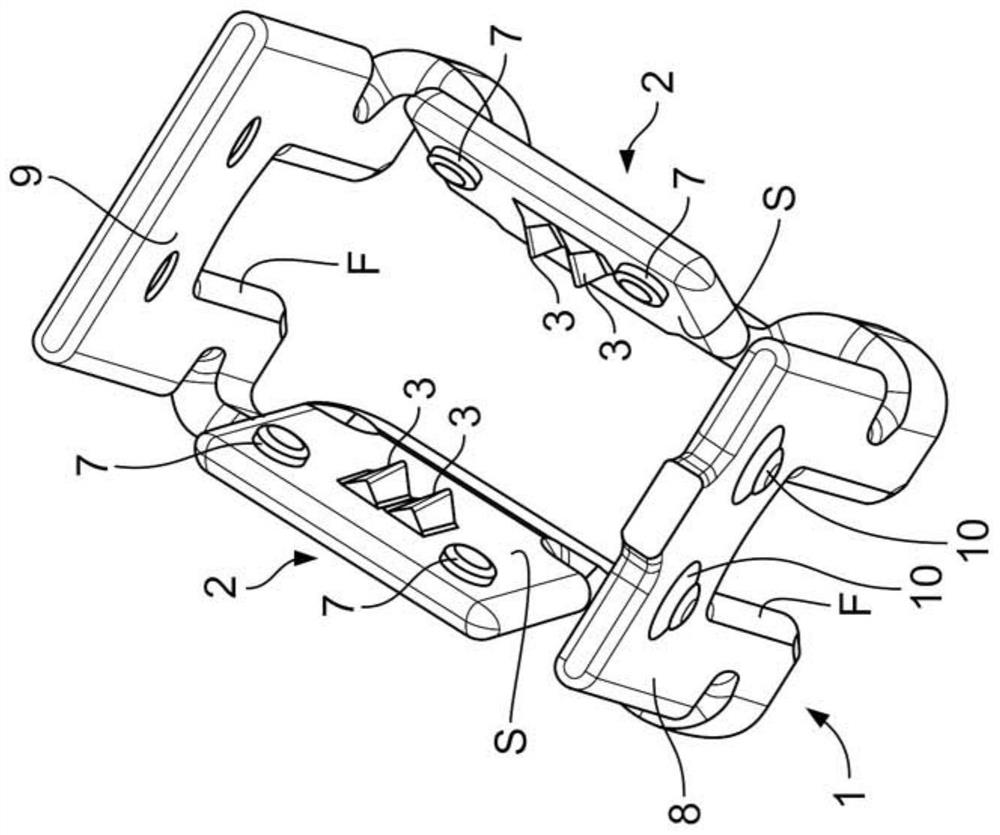

[0036] In the drawings, reference sign C denotes a preferred embodiment of the electrical connector according to the present invention. exist figure 1 , connector C is connected to the magnetic ignition coil B of the internal combustion engine. In a conventional production process, the connector C is obtained by cutting to a suitable size and bending a sheet metal plate. The details of the construction relating to the manufacturing process of the ig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com