A busbar support device and a busbar transmission system using the support device

A busbar support and power transmission system technology, which is applied to fully enclosed busbar devices, busbar installation, electrical components, etc. Convenient, flexible installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

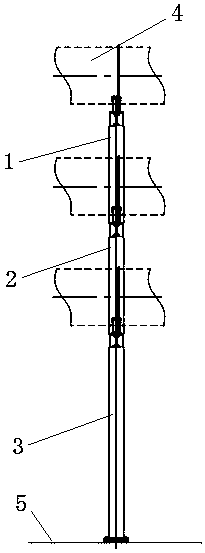

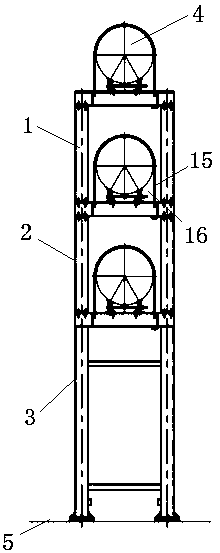

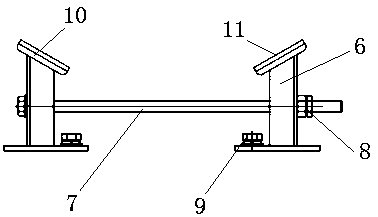

[0025] Embodiment 1 of a busbar power transmission system of the present invention, such as Figure 1 to Figure 4 As shown, the three-layer busbars and busbar support devices arranged in sequence from top to bottom, the busbar support device includes an upper support layer 1, a middle support layer 2 and a lower support layer for supporting the corresponding busbars arranged in sequence from top to bottom 3. The busbar 4 includes a busbar casing and a busbar conductor arranged in the busbar casing. Each support layer includes a base frame, each base frame is provided with a support structure, and each base frame is formed by welding H steel. supporting structures such as image 3 As shown, it includes support beams 6 symmetrically arranged along the radial direction of the busbar, and insulating backing plates 10 arranged obliquely to form a V-shaped p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com