A double-string motor for a submersible pump

A technology for submersible pumps and motor housings, which is applied in the field of motor devices for submersible pumps and double-series motors for submersible pumps. It can solve problems that affect the transportation and movement of the device, require high space, and cost high, and reduce complexity. Degree and volume, high head, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail through the following examples, which are illustrative rather than restrictive, and cannot limit the protection scope of the present invention.

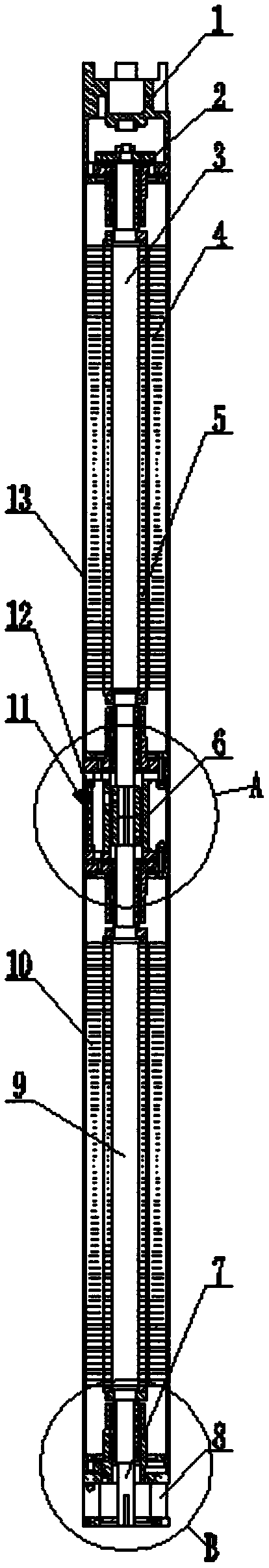

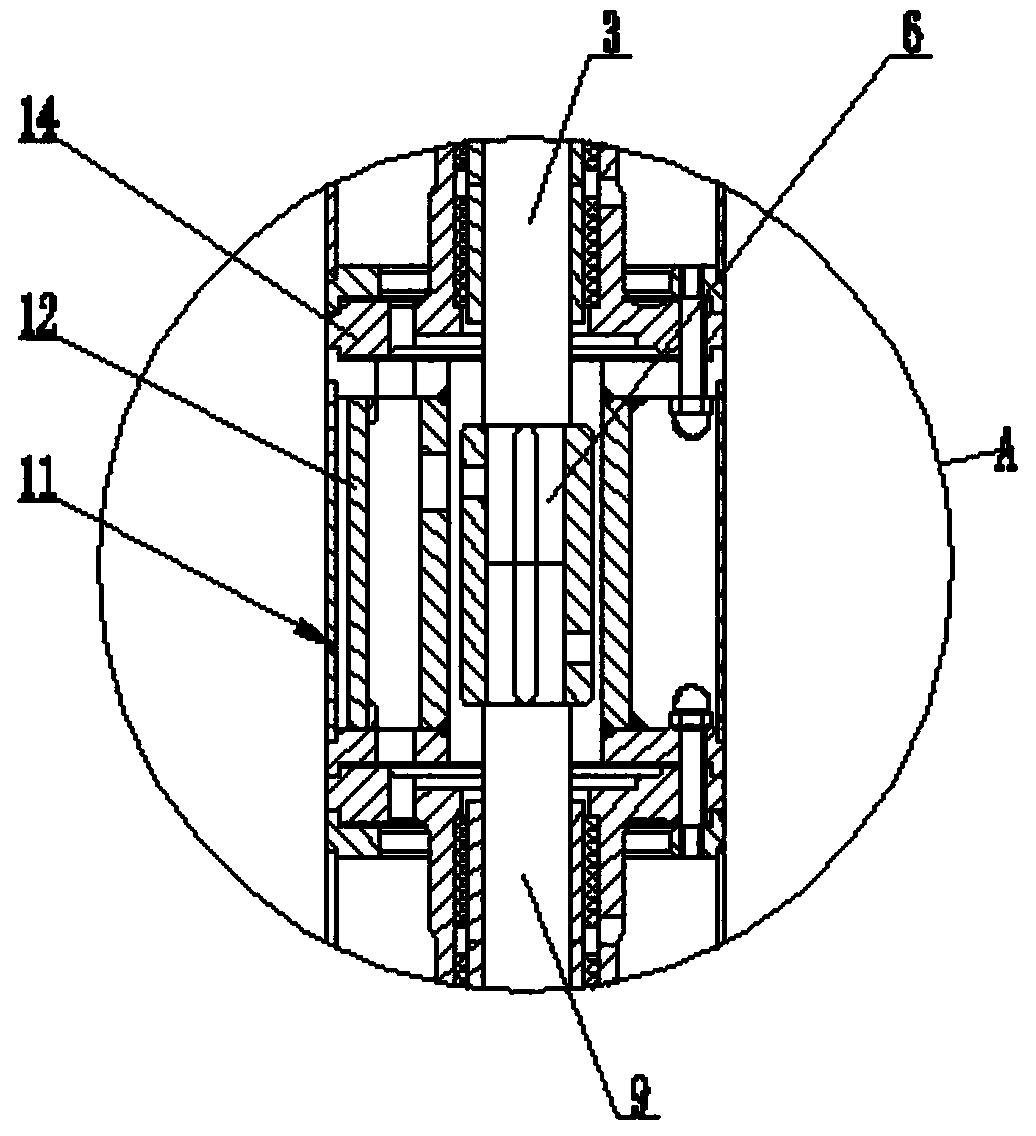

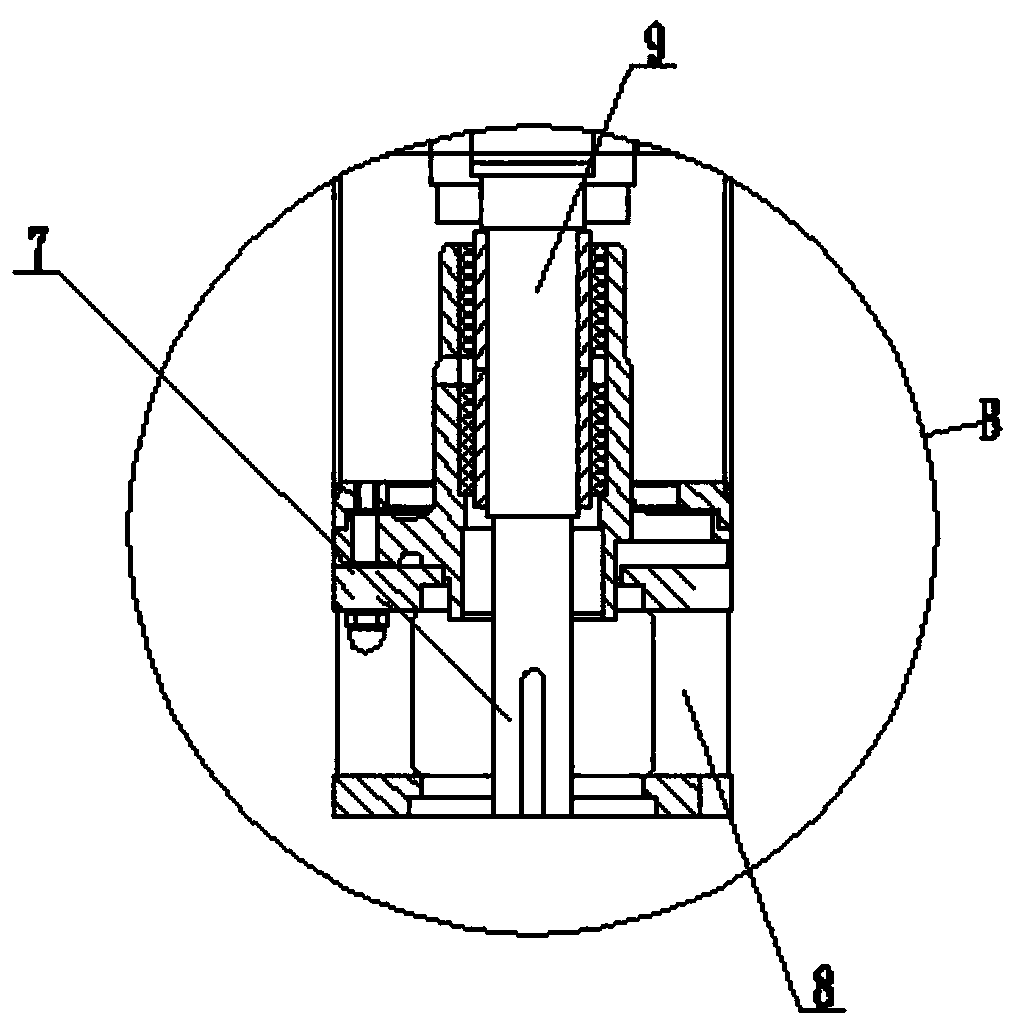

[0018] A double-string motor for a submersible pump, including a motor housing 13. The innovation of the present invention is that a first main shaft 3 and a second main shaft 9 are sequentially installed in the motor housing. The first main shaft and the second main shaft The two main shafts rotate synchronously and at the same speed. The outer sides of the first main shaft and the second main shaft are respectively equipped with rotors 5, and the first stator 4 and the second stator 10 are respectively installed on the inner edges of the motor housing corresponding to the rotors. The circuits of the first stator and the second stator are connected in series.

[0019] In this embodiment, the first main shaft and the second main shaft respectively use iron core bars as rotors. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com