Horn temperature testing system and method based on phase change measurement

A phase change and test system technology, applied in the direction of electrical components, etc., can solve the problems of area consumption and power consumption, power amplifiers and filters, occupying a large area, and occupying a large area, so as to reduce complexity, occupy a small area, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

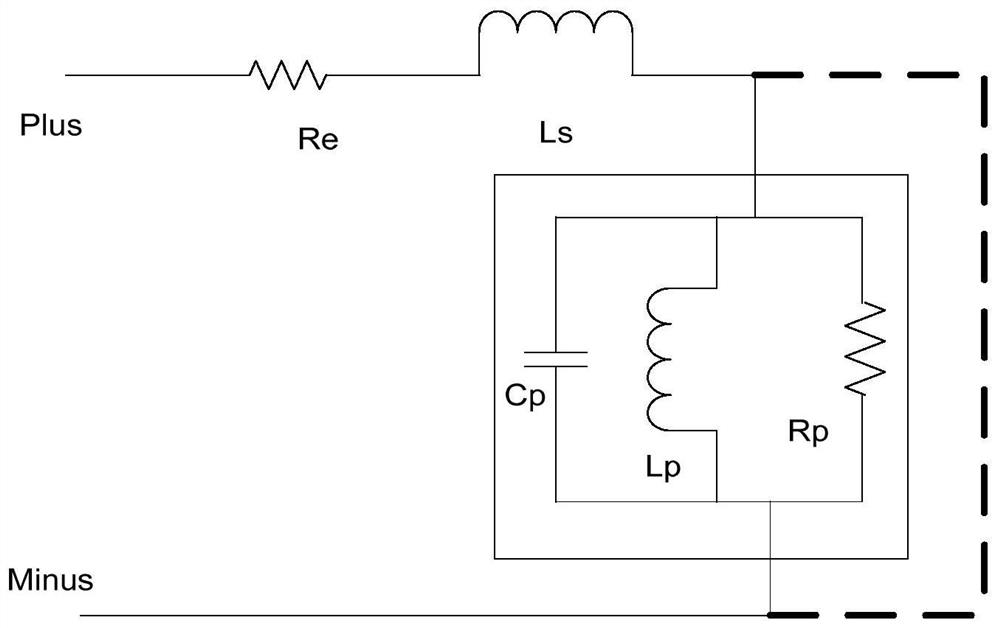

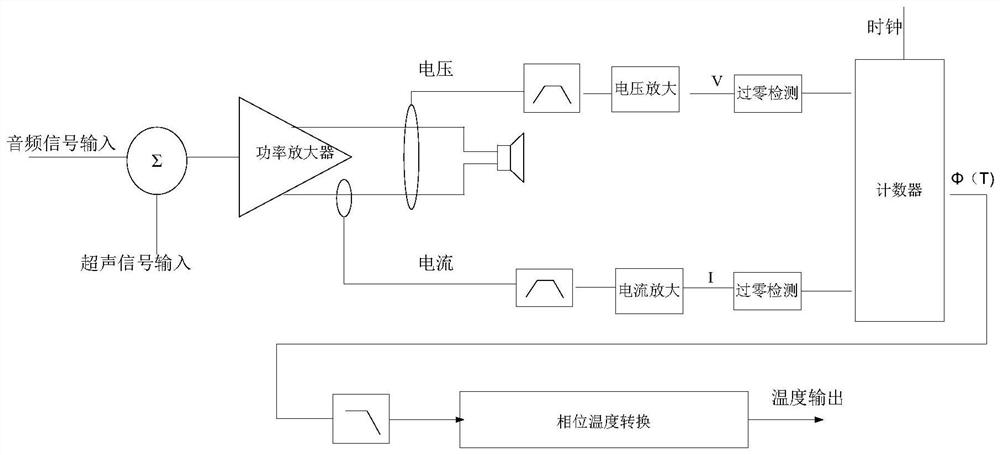

[0080] This embodiment provides a horn temperature testing system based on phase change measurement, such as figure 2 As shown, it includes: an adder, a power amplifier connected to the output of the adder, a voltage processing component and a current processing component connected to the output of the power amplifier and arranged in parallel, a counter connected to the output of the voltage processing component and the current processing component, connected to A phase temperature converter at the output end of the counter; the voltage processing component and the current processing component both include a band-pass filter, an amplification circuit and a zero-crossing detection circuit arranged in sequence;

[0081] in:

[0082] The adder adds the input audio signal and the ultrasonic signal used for testing to obtain a sum signal, and outputs it to the power amplifier;

[0083] The power amplifier amplifies the obtained sum signal, and outputs a voltage signal and a curre...

Embodiment 2

[0119] This embodiment provides a horn temperature testing method based on phase change measurement, using the horn temperature testing system based on phase change measurement provided in Embodiment 1, such as Figure 4 shown, including the following steps:

[0120] Step S1, adding the input audio signal and the ultrasonic signal used for testing to obtain a sum signal;

[0121] Step S2, amplifying the sum signal, and outputting a voltage signal and a current signal to drive a load;

[0122] Step S3:

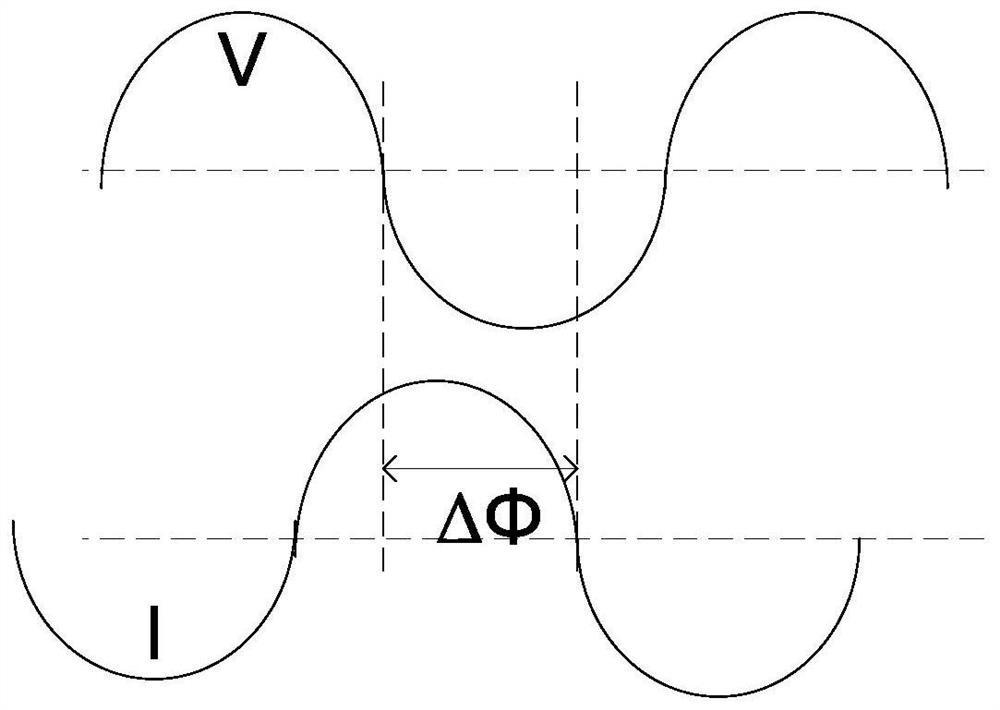

[0123] - extract the ultrasonic voltage signal in the output voltage signal, amplify the ultrasonic voltage signal, and perform zero-crossing detection on the amplified ultrasonic voltage signal to obtain the voltage zero-crossing moment;

[0124] - Extract the ultrasonic current signal in the output current signal, amplify the ultrasonic current signal, and perform zero-crossing detection on the amplified ultrasonic current signal to obtain the current zero-crossing moment; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com