A copper clad laminate using inverted copper foil material and a production process thereof

A production process and technology for copper clad laminates, applied in the field of reversed copper foil copper clad laminates, can solve the problems of increased difficulty in PCB pattern transfer process, increased risk of defective gaps, open circuits, etc., to reduce defects, improve open circuits, and improve adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

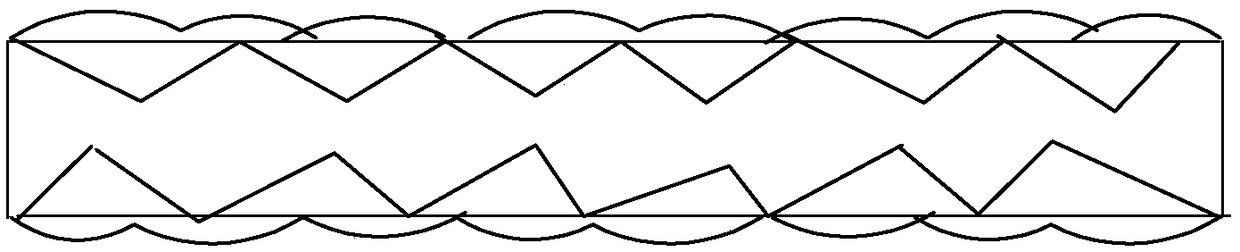

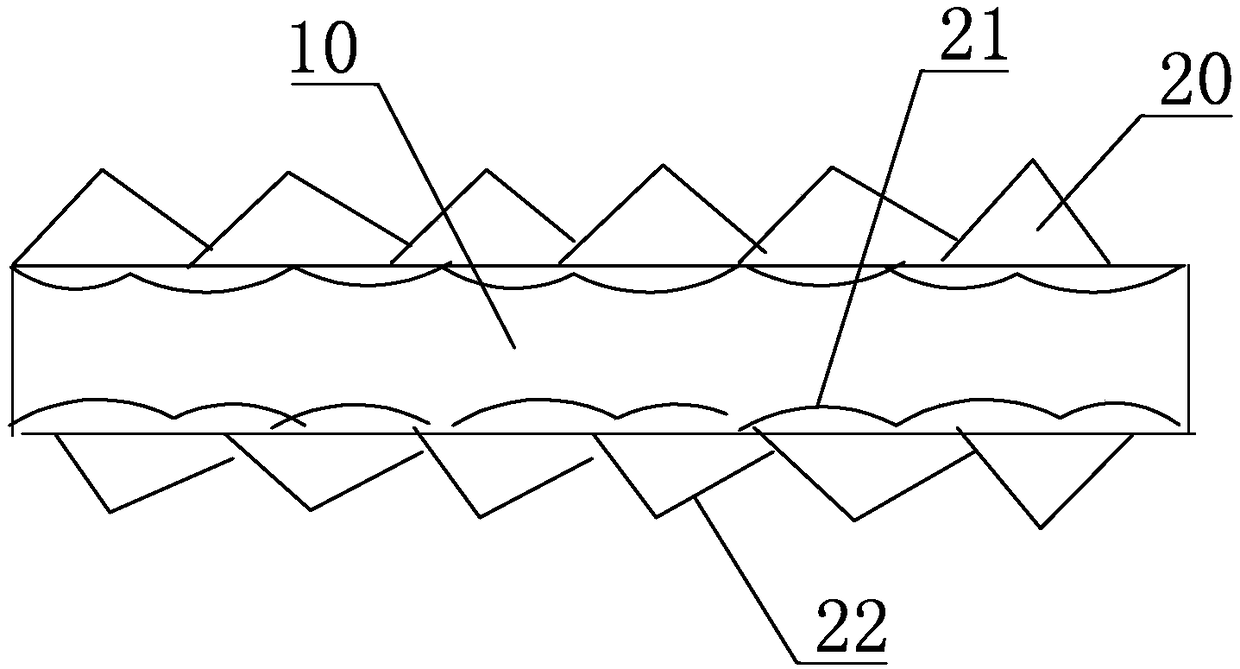

[0019] refer to Figures 1 to 2 , a copper clad laminate using a reversed copper foil material, including a reversed copper foil material and an etch resist bonded to its surface, the reversed copper material includes an insulating layer 10 and a copper layer 20, and the insulating layer 10 is placed In the middle, the copper layer 20 is covered on both sides of the insulating layer 10, and one side of the copper layer 20 is a smooth surface 21, and the other side is a matte surface 22 whose roughness is greater than that of the smooth surface 21. The insulating layer 10 is bonded, and the rough surface 22 faces the outside and is bonded with the etch resist. The thickness of the copper layer 20 on both sides of the insulating layer 10 is the same. The roughness of the rough surface 22 is between 3.5-5um, and can be specifically set to 4um. Both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com