Dynamoelectric machine having a thermosiphon

A technology of electric motors and hollow shafts, applied in the field of hollow shafts, to achieve stable air tightness, improve efficiency, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

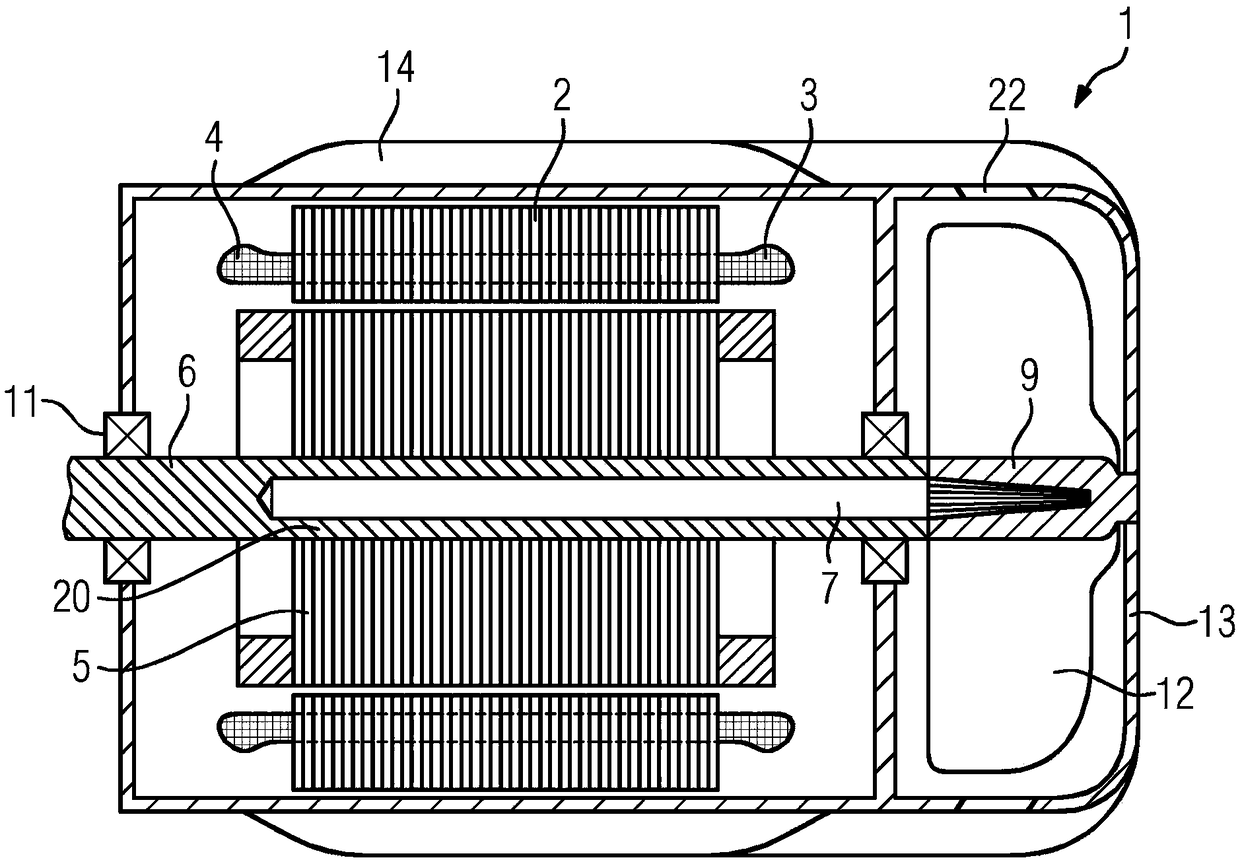

[0033] figure 1 A rotary electric motor 1 is shown having a stator 2 and a rotor 5 . In this embodiment, the rotor 5 is designed as a cage rotor, but it can also be a permanently excited rotor, a rotor of a reluctance machine or a rotor with a winding system.

[0034] The rotor 5 is connected in a rotationally fixed manner to the hollow shaft 6 , wherein the hollow shaft 8 is mounted in bearings 11 . A torsionally fixed connection is understood here to be a torque-transmitting connection, for example a heat shrink connection or a keyed connection or another hub connection between the laminated core of the rotor 5 and the hollow shaft 8 . The housing of the motor 1 carries the bearing housing. On the radially outer housing of the stator 2 there are axially extending cooling ribs 14 which guide the cooling air flow generated by the fan 12 along the housing. In this case, the fan 12 is mounted in a fan hood 13 , which optionally has an opening 22 .

[0035] In this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com