Special bag cage for filtering materials

A special-shaped, filter material technology, applied in the direction of filtration separation, gravity filter, fixed filter element filter, etc., can solve the problems of easy blockage of the discharge port and poor filtering effect, and achieve better results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

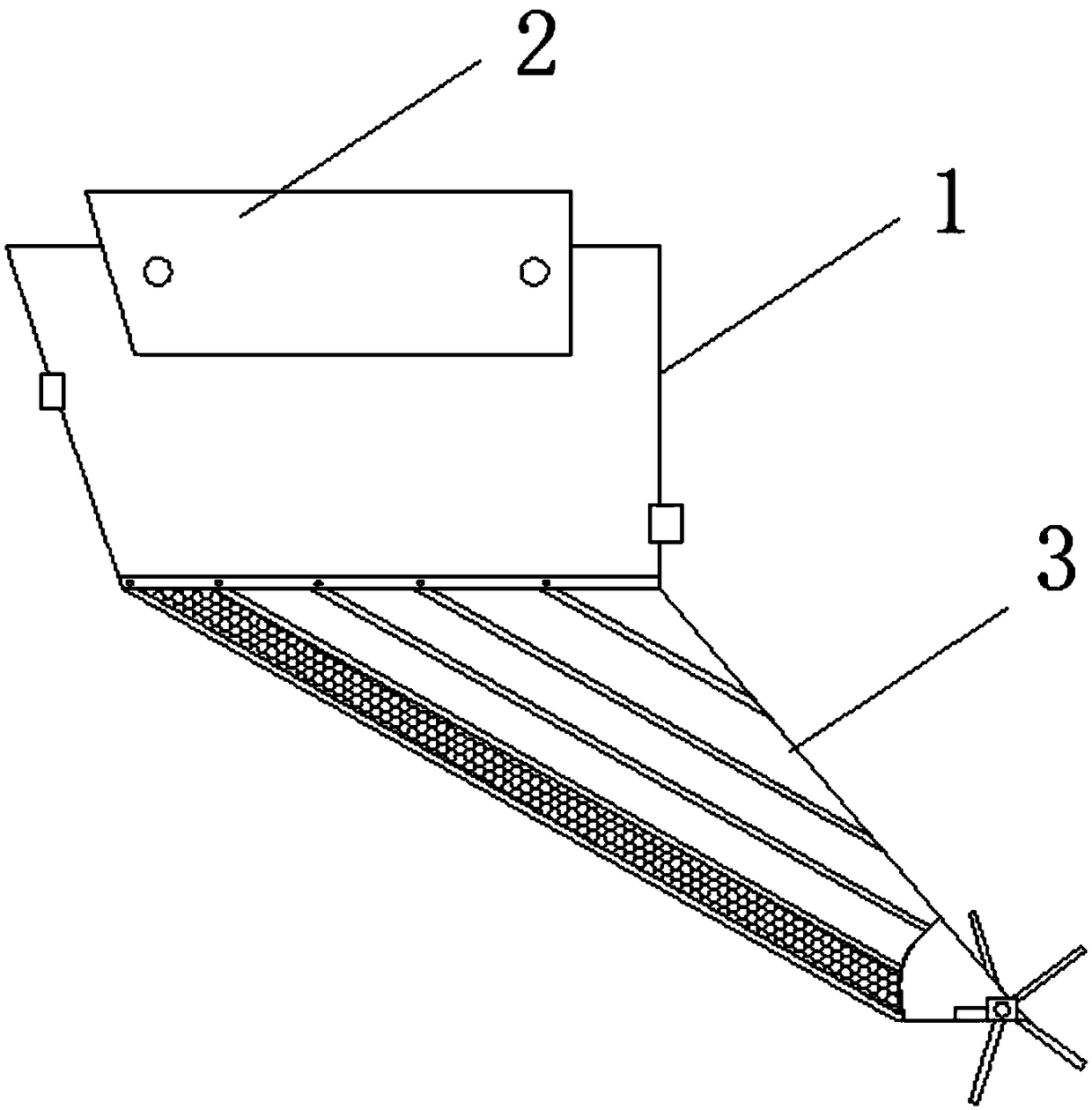

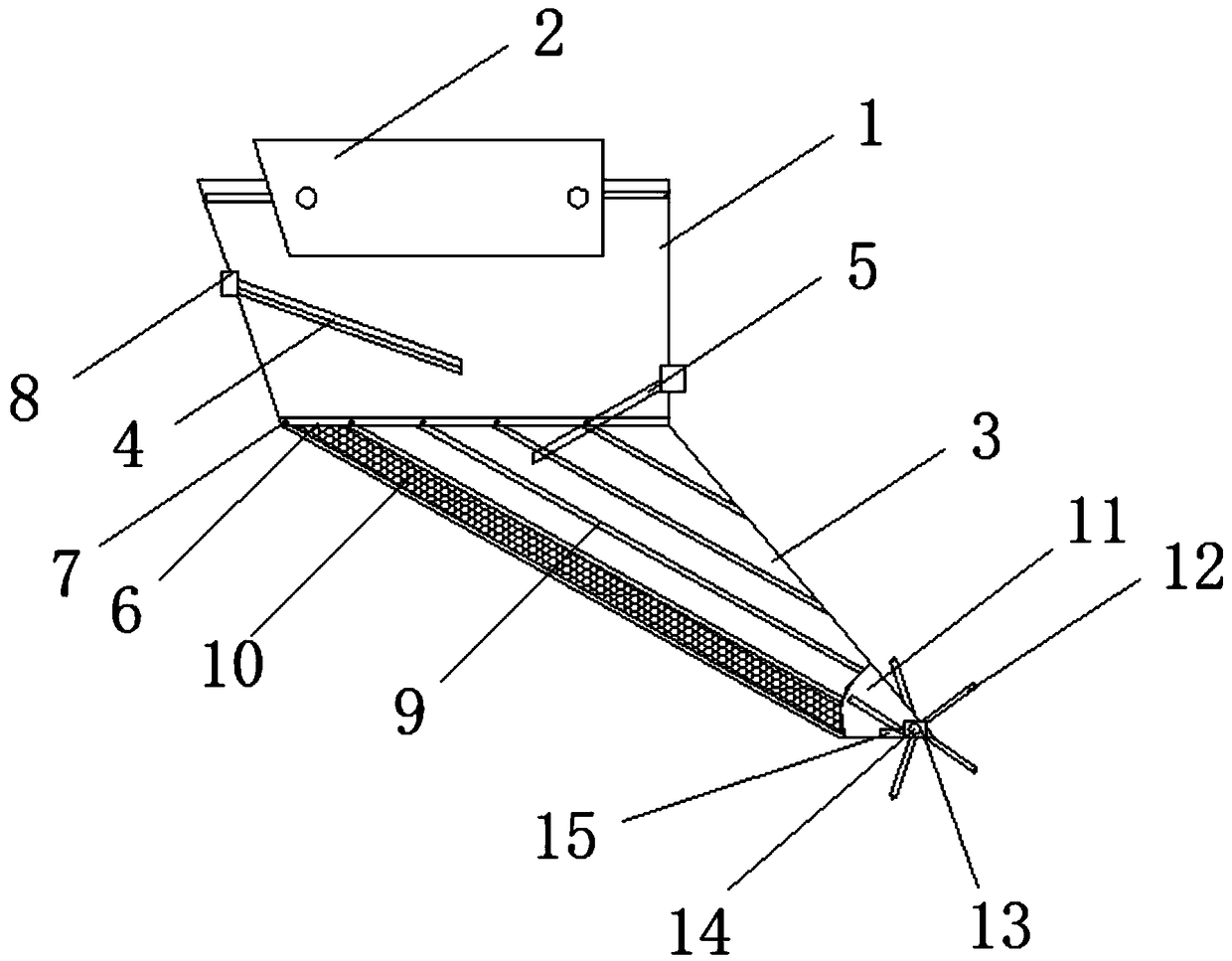

[0018] see Figure 1-2 As shown, a special-shaped bag cage for filter material includes a feed hopper 1 and a bag cage 9 at the bottom thereof. The top of the feed hopper 1 is provided with a feed inlet 2, and a filter bag 3 is sleeved on the outer wall of the bag cage 9. And the bottom of the bag cage 9 is provided with a discharge port 11, the first filter plate 4 is installed on the inner wall of one side of the feeding hopper 1, and the second filter plate 5 guiding the inside of the bag cage 9 is installed on the outer wall of the other side of the feeding hopper 1; The top of each skeleton constituting the bag cage 9 is connected to the bottom of the feed hopper 1, and a seal 6 is installed at the joint between the bag cage 9 and the feed hopper 1, and several screw holes 7 are arranged on the seal 6, and the bag A layer of screen 10 is sleeved on the inner wall of the inclined side of the cage 9, so that the filter material in the area where the material is accumulated ...

Embodiment 2

[0020] Please continue to refer to Figure 1-2 The difference between it and the above-mentioned embodiment is that one end of the first filter plate 4 and the second filter plate 5 are respectively inserted into two joints 8 located on the inner wall of the feed hopper 1 and fixed. The angle between the first filter plate 4 and the inner wall of the feed hopper 1 is 45°, and the angle between the second filter plate 5 and the inner wall of the feed hopper 1 is 60°, so that when the material enters from the feed hopper 1 It can be filtered by the filter holes on the two filter plates and flow to the inside of the filter bag 3 under the guidance of the second filter plate 5 . Each skeleton of the bag cage 9 is connected to a corresponding screw hole 7, and the bag cage 9 is fixedly connected with the feed hopper 1 and the filter bag 3 by a seal 6, so that the feed hopper 1 and the bag cage 9 and The filter bag 3 constitutes a stable whole, and a special-shaped bag cage is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com