Internal cleaning device for coating environmental protection machinery and equipment

A technology for mechanical equipment and internal cleaning, applied in the direction of injection devices, etc., can solve the problems of affecting air intake, increasing resistance, and surplus capacity, and achieve the effect of avoiding premature replacement, reducing use costs, and surplus capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

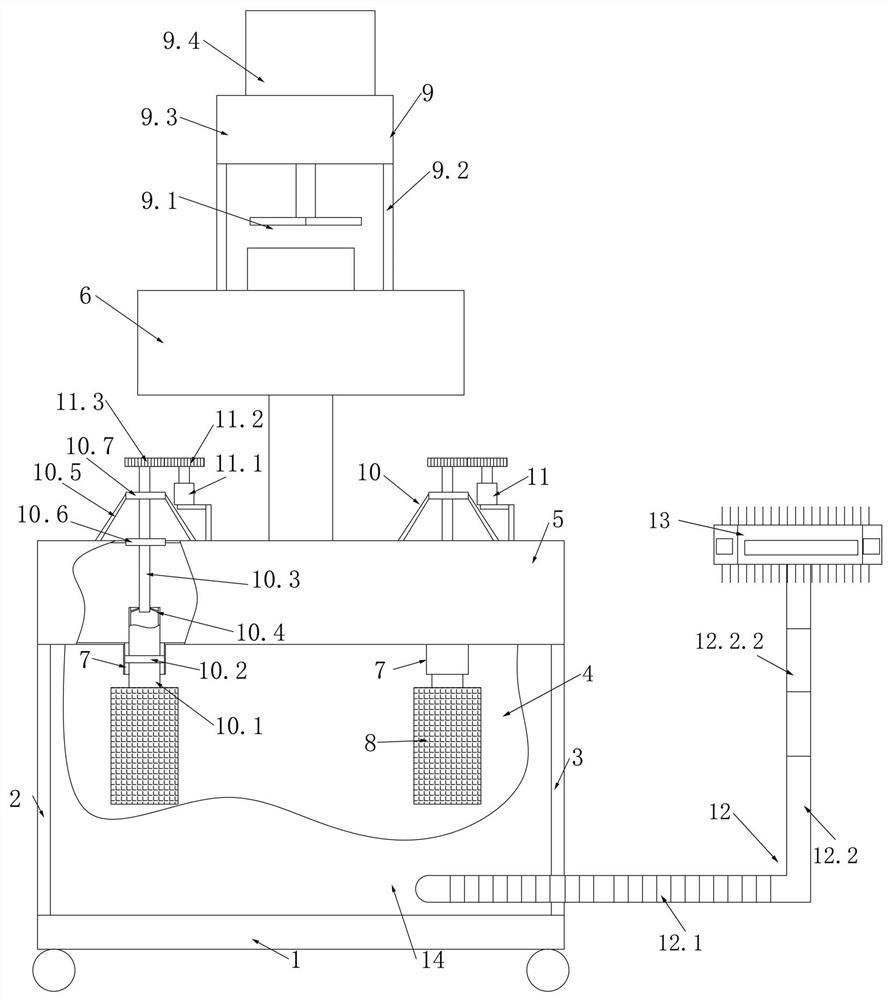

[0023] Such as figure 1 As shown, the internal cleaning device of the coating environmental protection mechanical equipment includes a walking chassis 1, a windshield, a wind collecting hood 5, an induced draft fan 6, an air inlet 7, a filter element 8, a connecting pipe 12, and a dust suction head 13 And detachable front mounting plate 14, the upper end of windshield is fixed on the bottom of wind collecting hood 5, and the lower end of windshield is fixed on the upper surface of walking chassis 1, and windshield comprises left side plate 2, right side plate 3 and The tailgate 4, the left and right ends of the tailgate 4 are respectively vertically connected with the left side board 2 and the right side board 3, and the upper ends of the left side board 2, the right side board 3 and the tailgate 4 are all fixed to the wind collecting hood 5 Connection, the lower ends of the left side plate 2, the right side plate 3, and the rear baffle plate 4 are all fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com