Multi-speed-ratio independent transmission rolling mill and rolling method

A technology with independent transmission and multiple speed ratios, which is applied in metal rolling, metal rolling, and driving devices for metal rolling mills. impact and other issues, to achieve the effect of simplifying the equipment structure, improving flexibility, and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

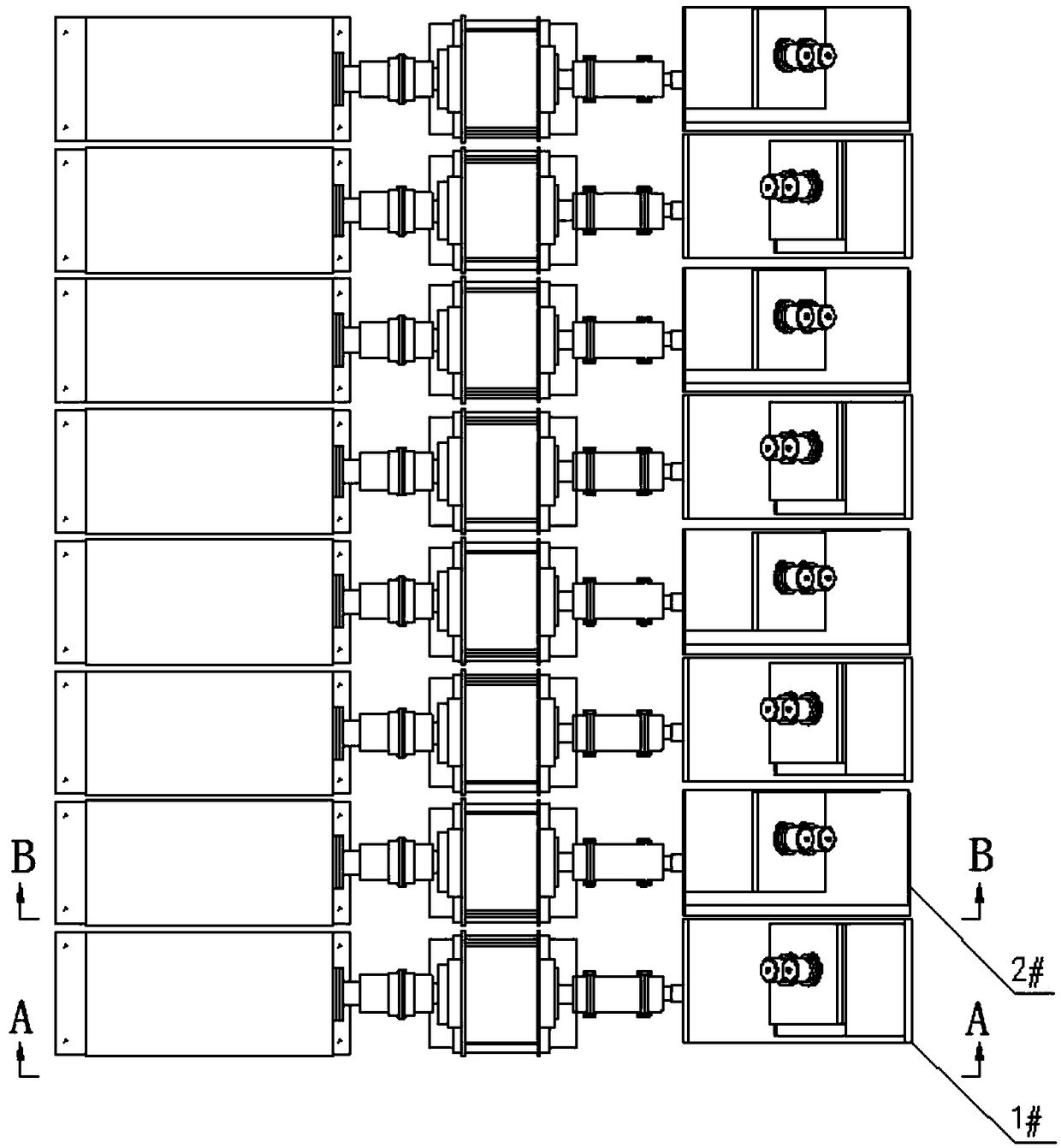

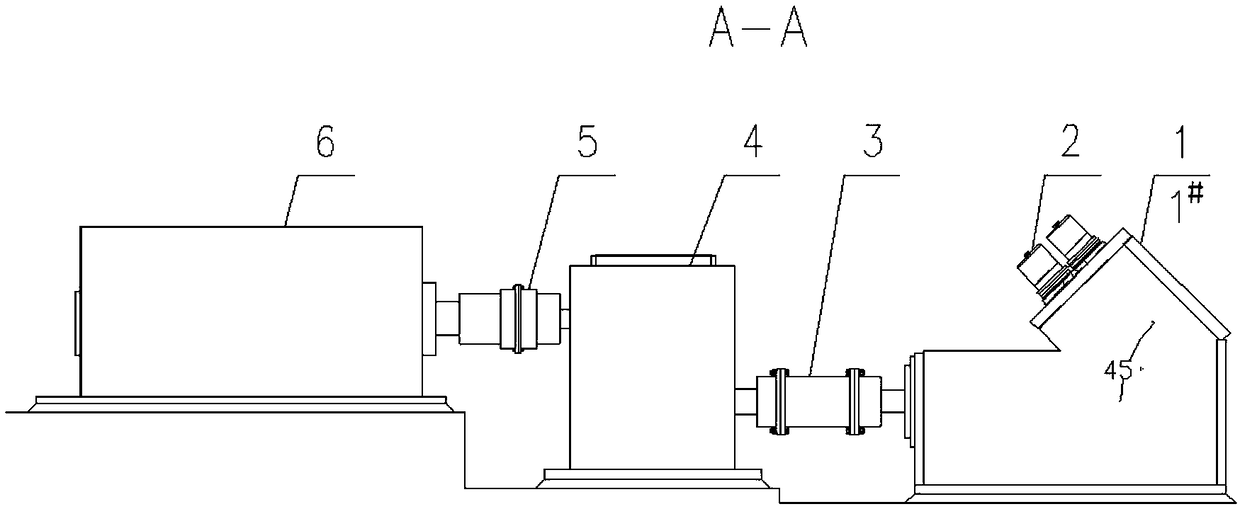

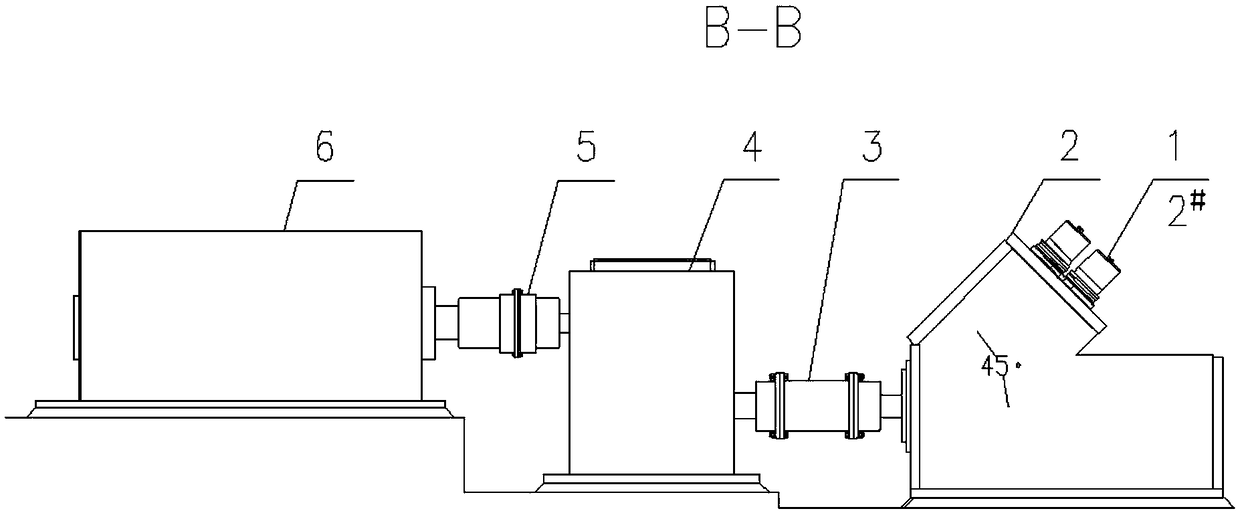

[0031] Such as Figure 1-4 As shown, this embodiment provides an independent drive rolling mill with double speed ratios, including a gearbox 4 with two speed ratios, a rolling mill 1 , and a motor 6 . The input shaft 4-1 of the gearbox 4 is provided with an idler gear 4a, and realizes synchronous rotation or free rotation with the input shaft 4-1 through the clutch 4-3. The output shaft 4-2 is provided with a fixed gear 4b which is fixedly connected with the output shaft, and is respectively meshed with the idler gear 4a on the input shaft 4-1, and the switching of different speed ratios is realized through the clutch 4-3. Under certain conditions, the rotational speed and torque of the output shaft 4-2 are changed to meet the speed ratio requirements of different rolling processes.

[0032] The input shaft 4-1 and the output shaft 4-2 of the gearbox 4 in this embodiment are vertically arranged to reduce the width of the gearbox so as to realize a compact arrangement.

[00...

Embodiment 2

[0035] Such as Figure 5 As shown, this embodiment is an independent transmission rolling mill with double transmission ratios like Embodiment 1, but the difference is that the clutch 4-3 of the gearbox 4 can also be arranged on the output shaft 4-2, that is, the input shaft 4 The fixed gear 4b provided on -1 is fixedly connected with the input shaft, and the idler gear 4a provided on the output shaft 4-2 is connected with the output shaft idler, which can also realize switching of different speed ratios.

Embodiment 3

[0037] Such as Image 6 As shown, the present embodiment is different from the above-mentioned embodiments in that it has an independent transmission rolling mill with multiple speed ratios, that is, the gearbox 4 can realize more speeds by increasing the number of intermediate shafts 4-4 and clutches 4-3. Ratio output, thus forming independent rolling mill row 1# and rolling mill row 2# with more speed ratios, increasing the output of speed ratios and the combination of speed ratios, further improving the flexibility of production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com