An automatic feeding device for stamping process of punch press

A technology of automatic feeding and punching, applied in the field of mechanical processing, can solve the problems of limited coil processing capacity, long time occupation, and small target volume, so as to improve equipment accuracy and operation stability, reduce labor costs, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

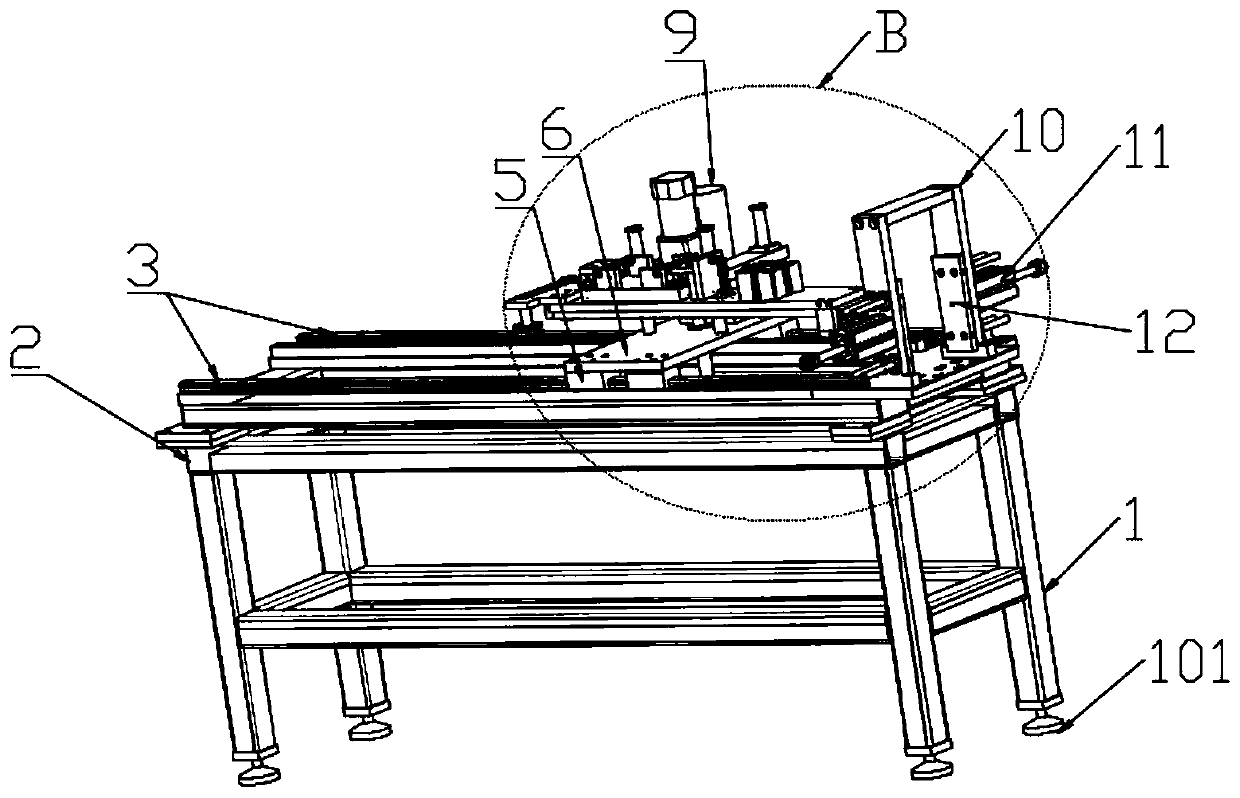

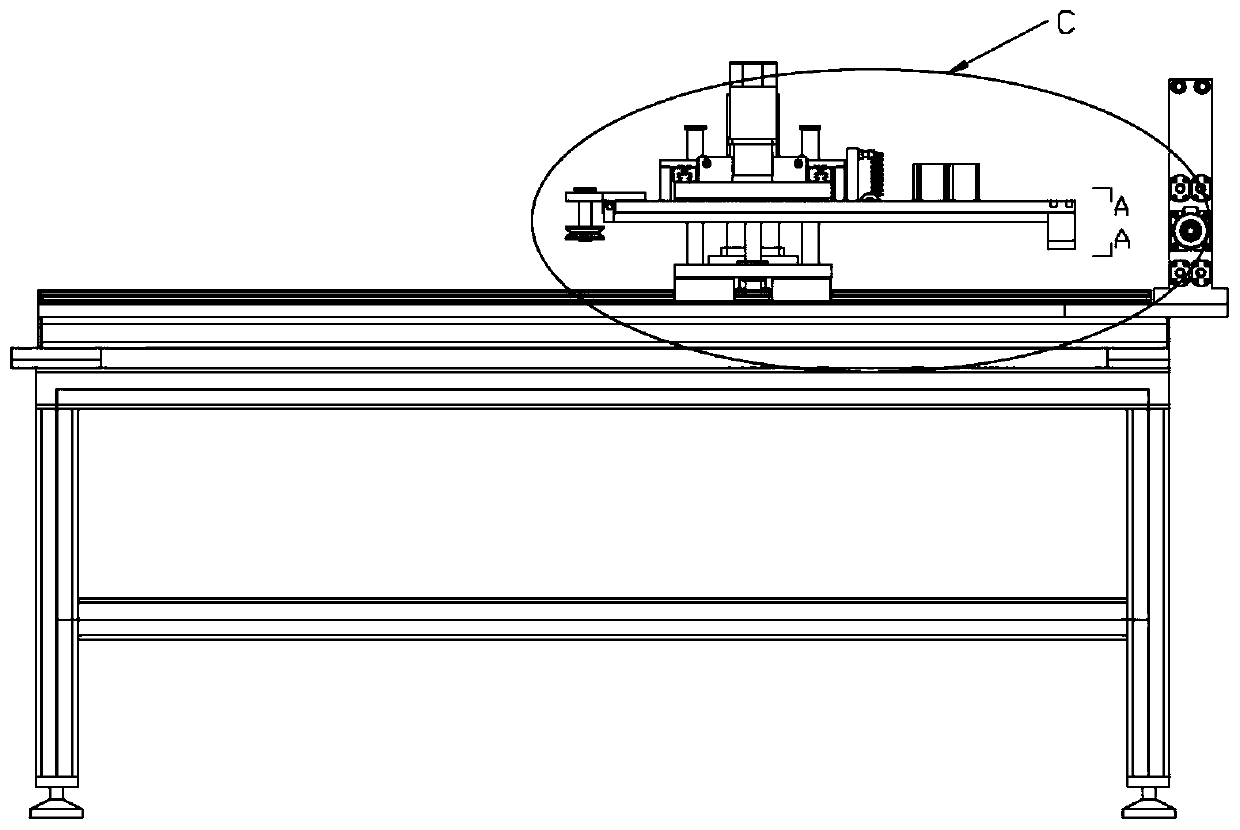

[0038] Such as Figure 1-6 Shown, a kind of automatic feeding device that is used for stamping process of punch press, comprises support 1, the workbench 2 that is fixed on described support 1, the feeding mechanism that is slidably arranged on described workbench 2, the described workbench 2 Slide rails 3 are fixedly arranged on both long sides, and a rack 4 is arranged parallel to one of the slide rails 3 .

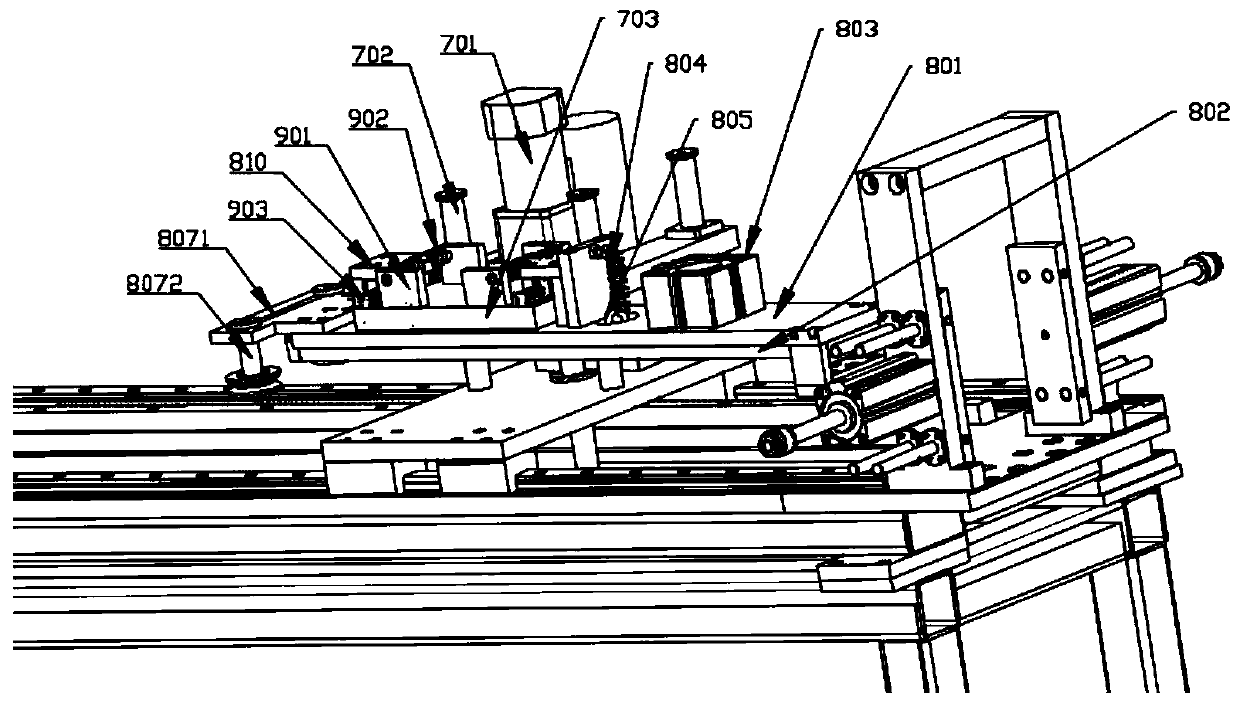

[0039]The feeding mechanism includes a feeding plate 6, a first slide block 5 that is located at the bottom of the feeding plate 6 and matches the slide rail 3, and a servo motor 9. The output end of the servo motor 9 is connected with the rack 4. The meshed gears, the present embodiment adopts the transmission mode of rack and pinion to drive the movement of the feeding mechanism, that is, the servo motor 9 drives the gear to rotate on the rack 4, and drives the feeding plate 6 to slide on the slide rail 3 to realize feeding. The plate 6 is provided with a lifting mec...

Embodiment 2

[0043] This embodiment is further optimized on the basis of Embodiment 1, and specifically includes a buffer mechanism, the buffer mechanism includes four fixed blocks 901, and the fixed blocks 901 are fixed on the upper surface of the fixed plate, The sidewalls of the fixed blocks 901 that are opposite to each other and arranged perpendicular to the direction of the slide rails are provided with second springs 902, and the second springs 902 are fixed to the connecting block 810, and the second spring 902 is fixed below the connecting block 810. Two sliders, and a linear guide rail 903 matching the second slider is set on the fixed plate 703. This buffer mechanism can effectively avoid the phenomenon that the equipment is easy to be stuck due to the size deviation of the material tape, and can play a role in buffer fine-tuning The role of increasing the stability of equipment operation. The setting of the linear guide rail 903 can further play the role of guiding and bufferin...

Embodiment 3

[0045] This embodiment is further optimized on the basis of embodiment 2, such as Image 6 As shown, specifically, the guide table 806 is provided with a mold 8061, and different molds are designed according to different profiles, which is convenient for replacement and has strong versatility; and / or the surface of the mold is provided with a layer of rubber pad 8062 to prevent damage to the mould. Scratch, but also reduce a certain amount of noise, prolong the life of the mold and optimize the working environment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com