Vehicle storage battery cover making die and making method

A manufacturing method and battery technology, applied in the field of automobile battery cover manufacturing, can solve the problems of increasing difficulty in quality control, secondary positioning error, large equipment footprint, etc., so as to reduce enterprise cost investment and ensure parts quality, the effect of improving the quality of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

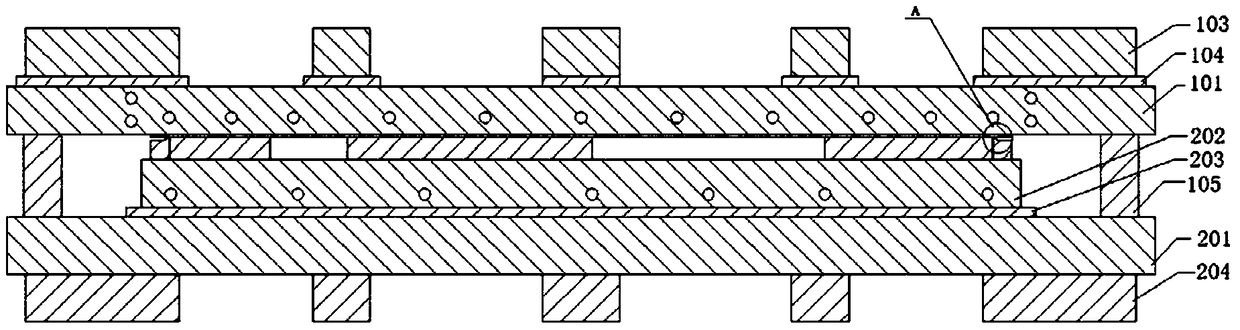

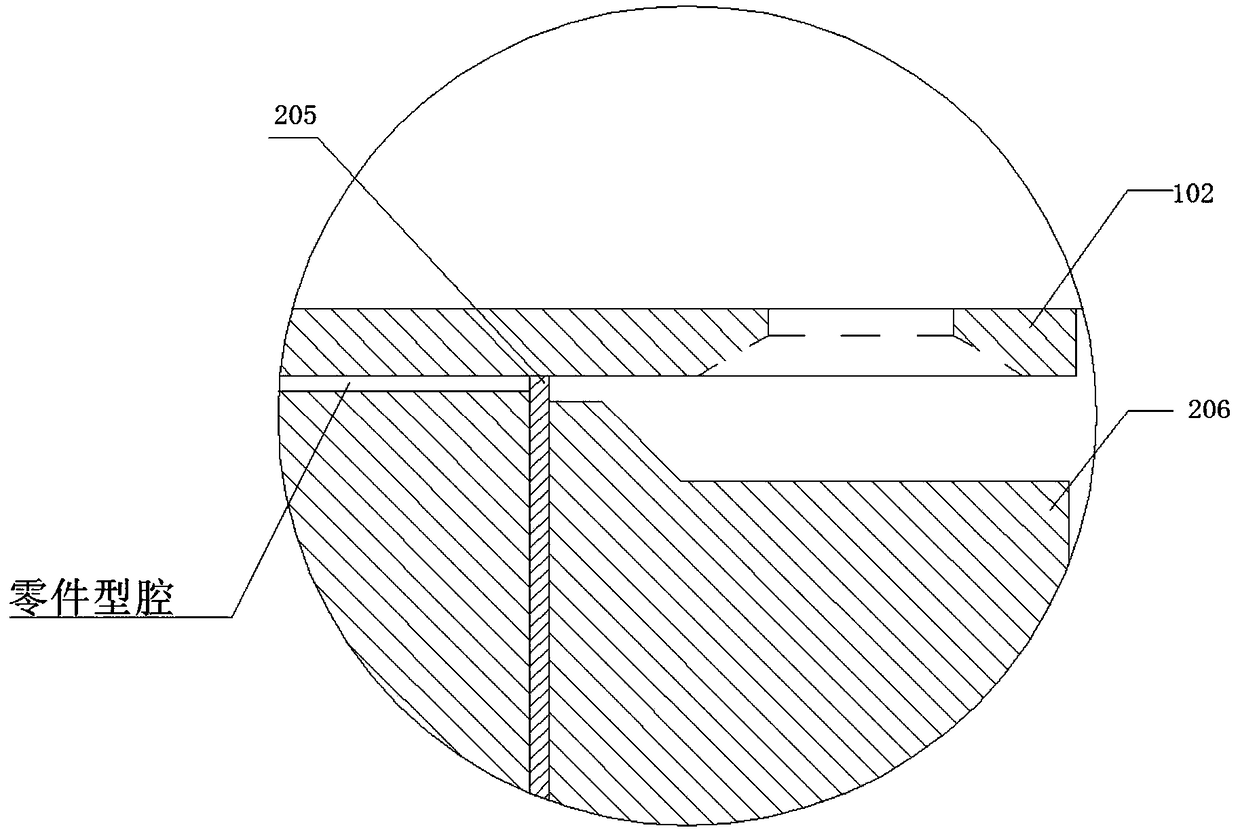

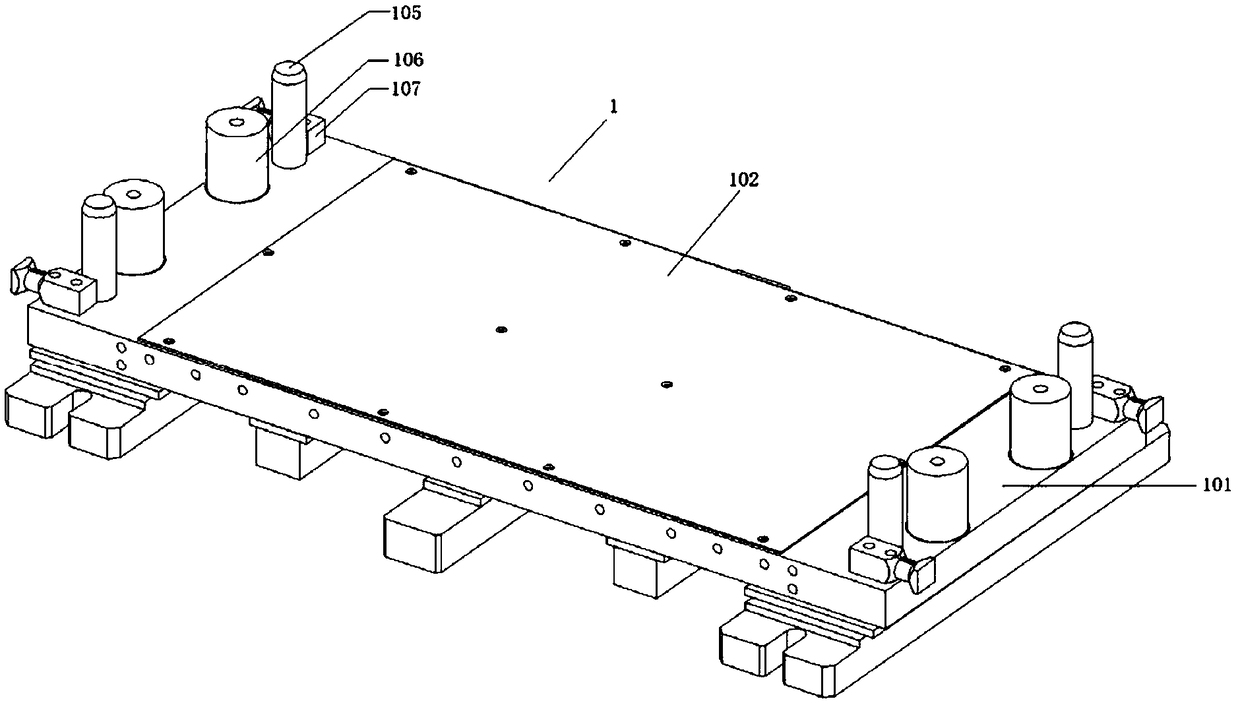

[0033] A kind of manufacturing mold of automobile battery cover, refer to Figure 1-4 , including upper mold 1 and lower mold 2, lower mold 2 is located at the below of upper mold 1, upper mold 1 comprises upper mold fixed plate 101 and is located at the upper mold impact plate 102 of upper mold fixed plate 101 bottom, and lower mold comprises The lower mold fixed plate 201 and the lower mold core 202 located at the upper part of the lower mold fixed plate 201, the lower mold fixed plate 201 bottom is provided with a lower mold spacer 204, the upper mold fixed plate 101 top is provided with an upper mold spacer 103, An upper mold heat insulating plate 104 is arranged between the mold cushion block 103 and the upper mold fixing plate 101 , and a lower mold insulating plate 203 is arranged between the lower mold core 202 and the lower mold fixing plate 201 . On both sides of the upper mold fixed plate 101, there are positioning guide pillars 105 and clamping pins 106. The height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com