Secondary positioning table suitable for bearing workpiece machining and positioning method

A positioning table and bearing technology, which is applied in the field of bearing workpiece processing, can solve the problems of not being stuck, changing the face, affecting the precision and accuracy of processing operations, etc., achieving strong practicability, ensuring precise contact, and improving safety protection sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

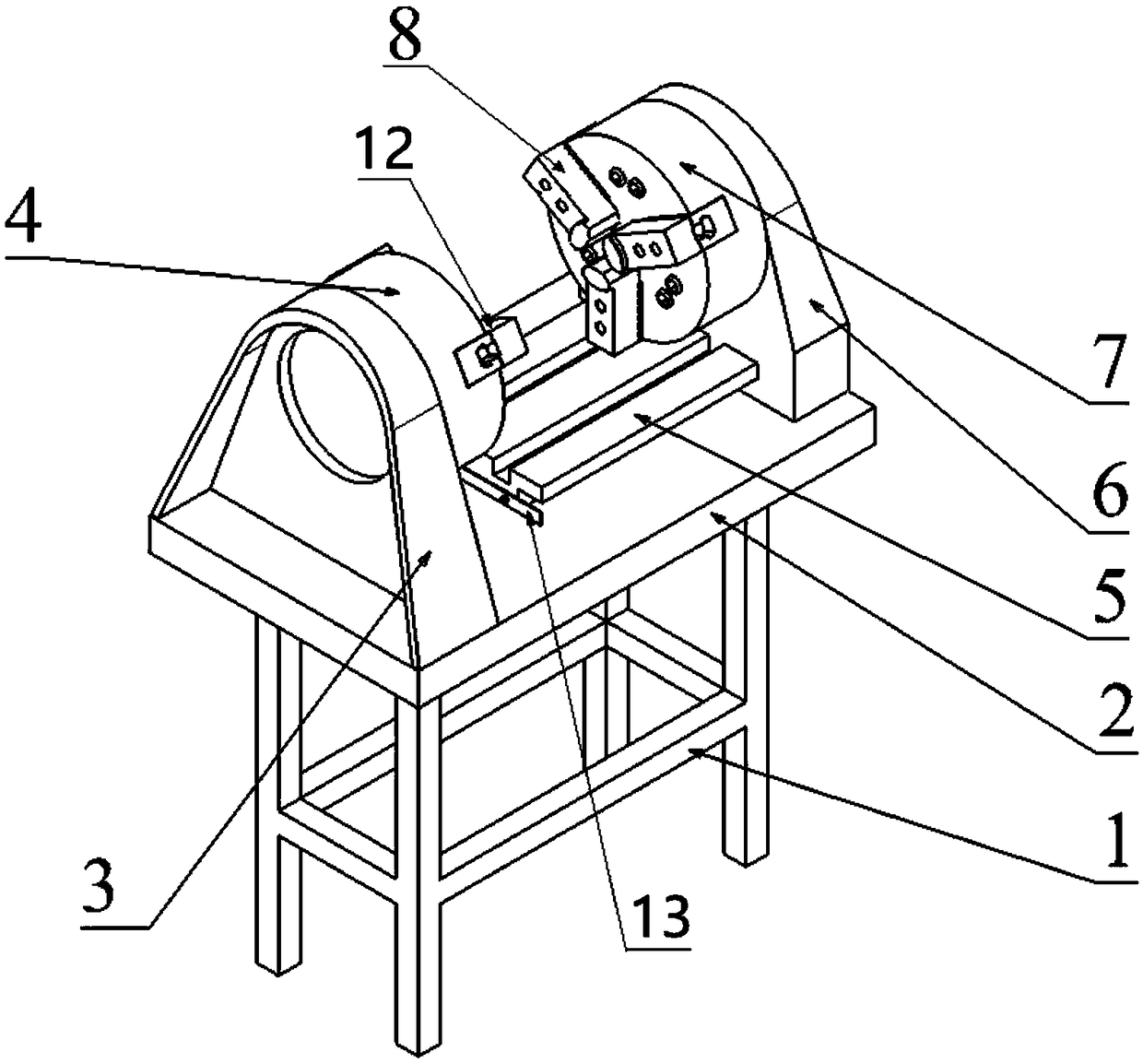

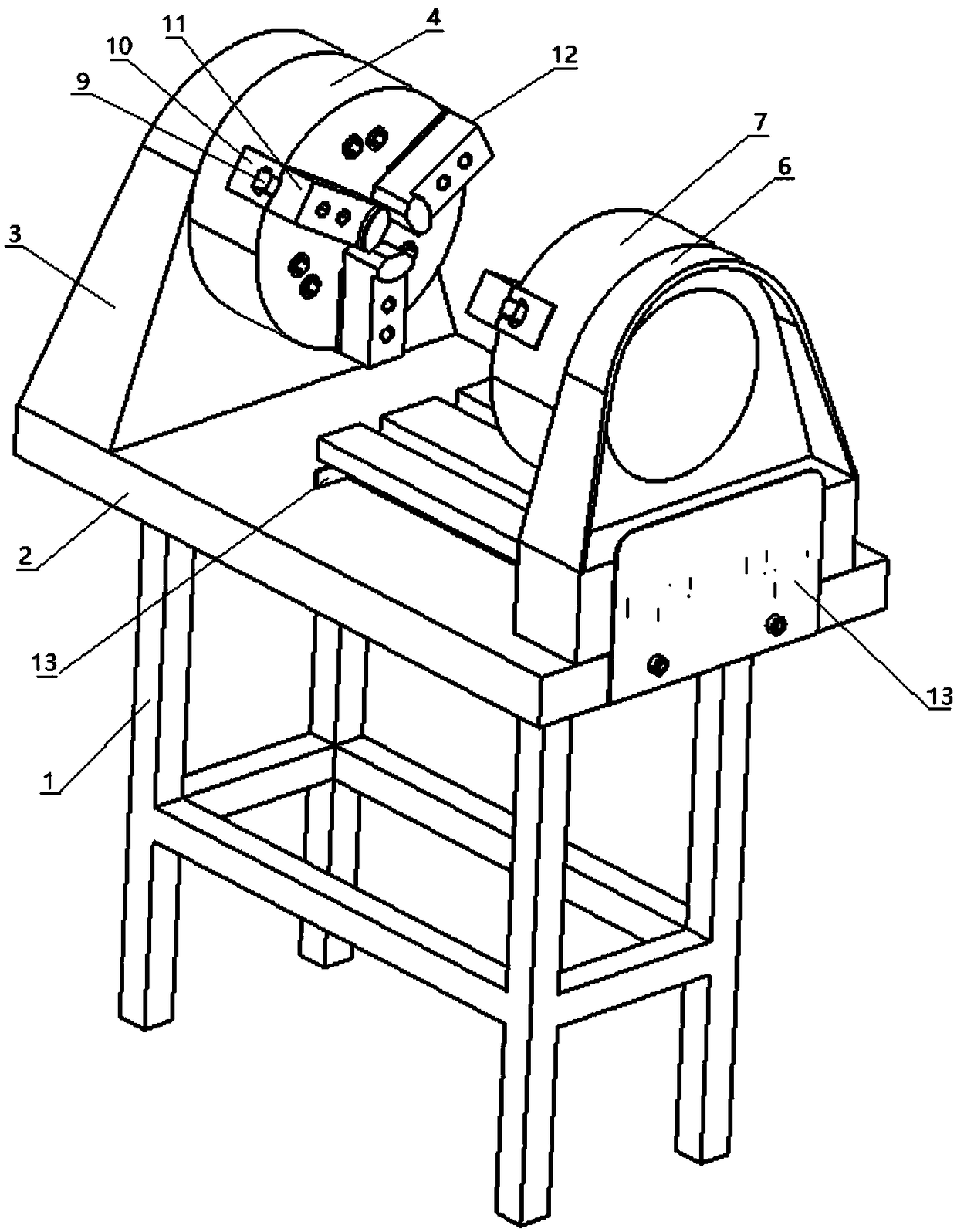

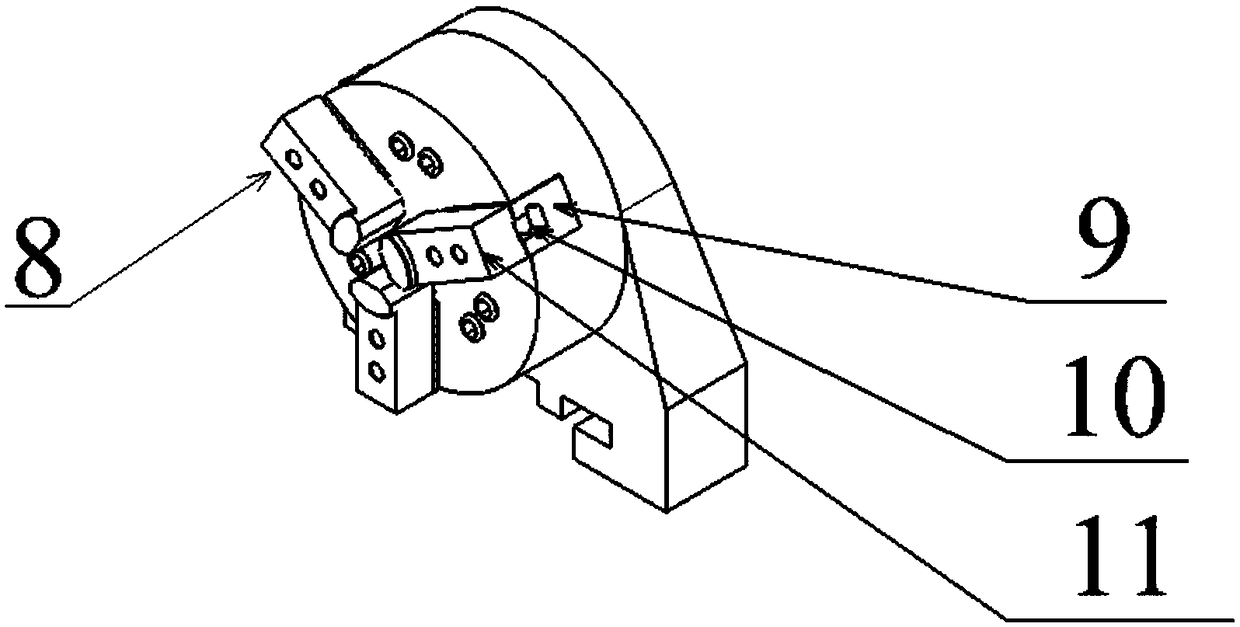

[0031] A secondary positioning table suitable for machining bearing workpieces, such as figure 1 , figure 2 with image 3 As shown, it includes a base support frame 1, a base support platform 2, a fixed chuck support 3, a fixed chuck base 4, a mobile transmission device 5, a mobile chuck support 6, a mobile chuck base 7, and a mobile chuck inner finger 8 , the chuck slider 9, the chuck finger pad 10, the chuck finger 11, the fixed chuck inner finger 12 and the baffle plate 13; the base support frame 1 is provided with a base support platform 2; The two ends of the upper surface of the base support platform 2 are relatively parallel with a fixed chuck support 3 and a movable chuck support 6;

[0032] The inner side of the upper part of the fixed chuck support 3 is provided with a cylindrical fixed chuck base 4, and the fixed chuck base 4 is provided with at least three fixed chuck internal grasping fingers 12, and the fixed chuck internal grasping fingers 12 include The chu...

Embodiment 2

[0037] A positioning method suitable for machining bearing workpieces, comprising the following steps:

[0038] a. The bearing workpiece is clamped and fixed by the finger 12 in the fixed chuck, and one end of the bearing workpiece is pushed against and fixed on the base 4 of the fixed chuck, and the processing operation of one end of the bearing workpiece is performed;

[0039] b. After the processing of one end of the bearing workpiece is completed, move the movable chuck base 7 along the mobile transmission device 5 to the fixed chuck base 4, so that the processed end of the bearing workpiece is pushed against the movable chuck base 7. The gripping finger 8 in the disk clamps and fixes the bearing workpiece;

[0040] c. Open the inner gripping finger 12 of the fixed chuck, move the movable chuck base 7 along the moving transmission device 5 away from the fixed chuck base 4 and return to the original position, complete the surface change, and then process the unprocessed end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com