Preparation process of wooden hanger

A preparation process and a technology for hangers, which are applied in the field of the preparation process of wooden hangers, can solve problems such as waste of tailings in the preparation process, and achieve the effects of excellent color and luster, low material loss and firm structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

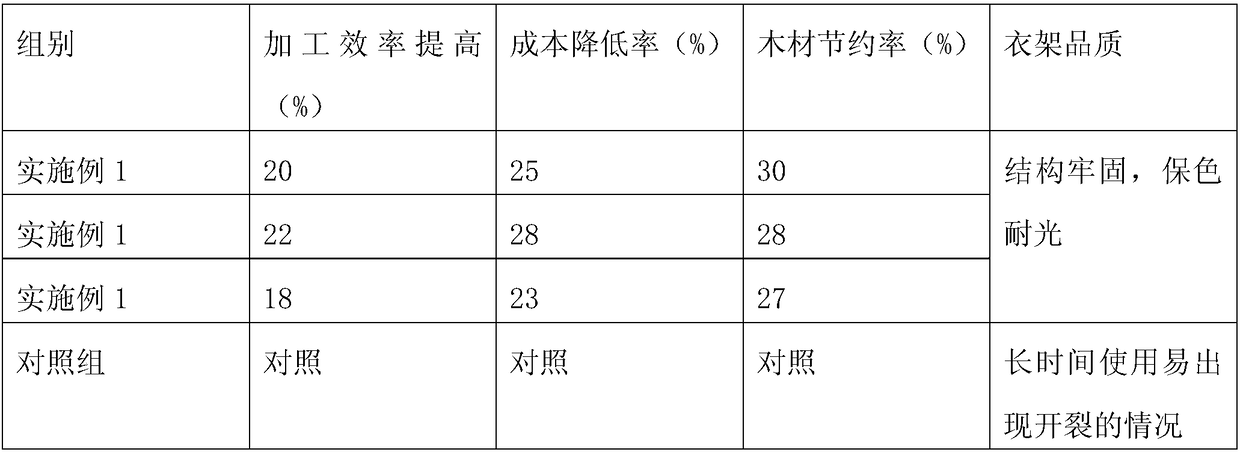

Examples

Embodiment 1

[0024] 1, a kind of preparation technology of wooden clothes hanger, comprises the following steps:

[0025] 1) Take a round bar with an outer diameter of 6 cm, cut it into quarters with a cutting tool to obtain four wood bars with a 90° arc surface, and cut the wood bars into sheets with a thickness of 0.8 cm The structure obtains the central skeleton connecting the left cantilever of the clothes hanger and the right cantilever of the clothes hanger.

[0026] 2) Take a cylindrical timber with an outer diameter of 15 centimeters, take the cylinder as the base body, take its inscribed square on its cross-section, and cut the cylinder axially along the side of the square to obtain 4 cross-sections with arc angles. It is an arc column formed by a 90-degree arc and a straight line and a cuboid whose cross section is a square.

[0027] 3) Butt the planes of the arc columns and bond them with glue to obtain rod-shaped wood. Before bonding the two arc columns, process the bonded sec...

Embodiment 2

[0030] 1, a kind of preparation technology of wooden clothes hanger, comprises the following steps:

[0031] 1) Take a round bar wood with an outer diameter of 7 cm, cut it into four equal parts with a cutting tool, and get four wood sticks with a 90-degree arc surface, and cut the wood sticks into sheets with a thickness of 1.5 cm The structure obtains the central skeleton connecting the left cantilever of the clothes hanger and the right cantilever of the clothes hanger.

[0032] 2) Take the cylindrical wood with an outer diameter of 20 centimeters and take the cylinder as the base body, take its inscribed square on its cross section, and cut the cylinder axially along the side of the square to obtain 4 cross sections with arc angles It is an arc column formed by a 90-degree arc and a straight line and a cuboid whose cross section is a square.

[0033] 3) Butt the planes of the arc columns and bond them with glue to obtain rod-shaped wood. Before bonding the two arc columns...

Embodiment 3

[0036] 1, a kind of preparation technology of wooden clothes hanger, comprises the following steps:

[0037] 1) Take the round bar wood with an outer diameter of 8 cm, cut it into four equal parts with a cutting tool, get four wood sticks with a 90 arc surface, and cut the wood sticks into sheets with a thickness of 2 cm The structure obtains the central skeleton connecting the left cantilever of the clothes hanger and the right cantilever of the clothes hanger.

[0038] 2) Take the cylindrical wood with an outer diameter of 30 centimeters, take the cylinder as the base body, take its inscribed square on its cross section, and cut the cylinder axially along the side of the square to obtain 4 cross sections. It is an arc column formed by a 90-degree arc and a straight line and a cuboid whose cross section is a square.

[0039]3) Butt the planes of the arc columns and bond them with glue to obtain rod-shaped wood. Before bonding the two arc columns, process the bonded section t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com