A preparation method of high-density multi-angle braided carbon fiber carbon cylinder

A carbon fiber carbon, multi-angle technology, applied in the field of preparation of high-density multi-angle weaving carbon fiber carbon cylinders, can solve the problems of large difference in internal and external density, low carbon fiber content, long production cycle, etc., to achieve uniform density, high carbon fiber content, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for preparing a high-density multi-angle braided carbon fiber carbon cylinder, specifically comprising the following steps:

[0048] (1) Use carbon fiber with a carbon content ≥ 92% as raw material, chop the carbon fiber, comb it into wool with a carding machine, and make it into a mesh tire. The weight of the mesh tire is 70g / m 2 , the carbon fiber arrangement direction is basically consistent with the plane where the mesh tire is located;

[0049] (2) Needling the single-layer mesh tire and unidirectionally arranged carbon fiber filaments into a unit layer by needle punching method, and the needle punching density is 2-50 needles / cm 2 ;Unit layer weight 280g / m 2 ;

[0050] (3) Needle-punching the two unit layers across each other to form a composite carbon fiber pre-punched layer;

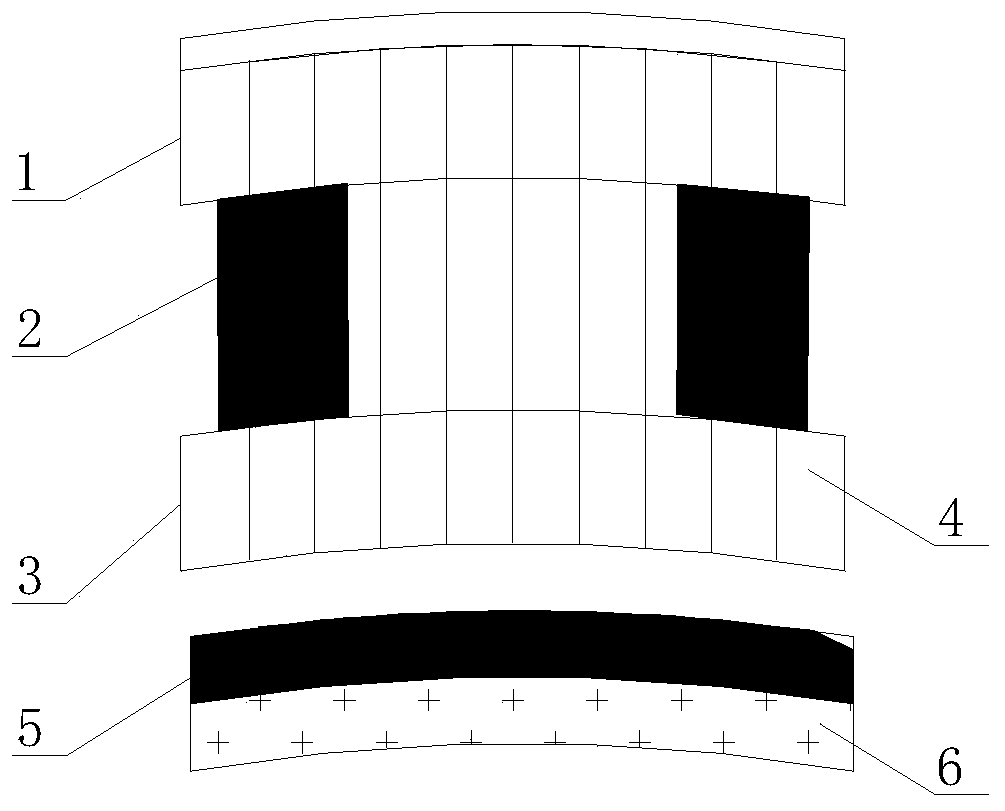

[0051] (4) Wrap the composite carbon fiber prepunched layer on the tray mold, such as figure 1 As shown, the composite carbon fiber pre-punched layer is repeatedly needled to...

Embodiment 2

[0060] A method for preparing a high-density multi-angle braided carbon fiber carbon cylinder, specifically comprising the following steps:

[0061] (1) Use carbon fiber with a carbon content ≥ 92% as raw material, chop the carbon fiber, comb it into wool with a carding machine, and make it into a mesh tire. The weight of the mesh tire is 80 g / m 2 , the carbon fiber arrangement direction is basically consistent with the plane where the mesh tire is located;

[0062] (2) Needling the single-layer mesh tire and unidirectionally arranged carbon fiber filaments into a unit layer by needle punching method, and the needle punching density is 2-50 needles / cm 2 ;The weight of the unit layer is 320 g / m 2 ;

[0063] (3) Needle-punching the two unit layers across each other to form a composite carbon fiber pre-punched layer;

[0064] (4) Wrap the composite carbon fiber prepunched layer on the tray mold, such as figure 1 As shown, the composite carbon fiber pre-punched layer is repea...

Embodiment 3

[0073] A method for preparing a high-density multi-angle braided carbon fiber carbon cylinder, specifically comprising the following steps:

[0074] (1) Use carbon fiber with a carbon content ≥ 92% as raw material, chop the carbon fiber, comb it into wool with a carding machine, and make it into a mesh tire. The weight of the mesh tire is 100 g / m 2 , the carbon fiber arrangement direction is basically consistent with the plane where the mesh tire is located;

[0075] (2) Needling the single-layer mesh tire and unidirectionally arranged carbon fiber filaments into a unit layer by needle punching method, and the needle punching density is 2-50 needles / cm 2 ;The weight of the unit layer is 320 g / m 2 ;

[0076] (3) Needle-punching the two unit layers across each other to form a composite carbon fiber pre-punched layer;

[0077] (4) Wrap the composite carbon fiber prepunched layer on the tray mold, such as figure 1 As shown, the composite carbon fiber pre-punched layer is repe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com